Original Article

, Volume: 15( 1)The Effect of Nd Nanoparticles on (Bi, Pb)-2223 Superconducting

- *Correspondence:

- Abdulridhaa AR College of Education for Pure Science, University of Babylon, Hilla, Iraq, Tel: 9647721500085; E-mail: ali_rzzq@yahoo.com

Received: February 21, 2017 Accepted: February 15, 2017 Published: March 20, 2017

Citation:Abbas MM and Abdulridhaa AR. The Effect of Nd Nanoparticles On (Bi, Pb)-2223 Superconducting. Int J Chem Sci. 2017;15(1):105.

Abstract

The prepared Superconducting samples achieved by a conventional solid-state reaction method and methodically deliberate for their superconducting properties. The Nd2O3 nanoparticles concentration x varied from 0.1 wt% to 0.6 wt%. Studying the effect of Nd nanoparticles (50 nm) on the physical properties of superconducting phase. The sightsaw of phase structural characteristics of synthesized thin films samples through powder X-ray diffractometer and reveals that all the samples crystallize in orthorhombic structure. Also, phase examination by XRD indicated that Nd nanoparticles enhanced the (Bi, Pb)-2223 phase formation. The standard DC four-probe method was used to measure the critical transition temperature (Tc) and found to have optimal value at x=0.2 wt%, which had a maximum enhancement in Tc for samples.

Keywords

(Bi, Pb)-2223; Nd nanoparticle;, solid state reaction

Introduction

The most essential discovery of the Bi-Sr-Ca-Cu-O (BSCCO) superconducting system was achieved by Maeda [1], which considered to be very important for practical applications meanwhile it has a large chemical resistance against moisture and stable in atmospheric pressure. For these reasons, many researchers study this system. Chen et al. [2] studied the superconductivity and microstructure of BSmCCO samples with the addition of small amounts of Nd nanoparticles additives were investigated. The Jc was enhanced, especially in high-field regions and in low-field regions by the Nd-BSmCCO samples. The Jc(H,T) and pinning behavior analysis both indicated the action of Tc pinning in the Nd doped samples The larger active region and the larger enhancement of Jc for the Nd doped samples could be attributed to the higher peritectic temperature, the higher solubility of Nd in liquid phase, and the larger size of Nd ions. Aloysius et al. [3] studied Phase evolution and superconducting properties of Nd added (Bi, Pb)-2223 superconductors in bulk form. The amount of Nd was varied from 0.005 to 0.030 on a general stoichiometry of Bi:Pb:Sr:Ca:Cu=1.85:0.35:2.0:2.1:3.1. Critical current density of all the samples was higher than that of the pure sample and it is more than twice for the sample with Nd=0.020. XRD analysis showed the presence of Bi-2212 even after the last stage of sintering for the samples with Nd=0.020 and 0.030. Microstructural analysis revealed that the morphology and texturing of all the samples are identical with a slight improvement for the Nd added samples.

It is likely that Nd may be substituted at Ca or Sr sites creating point defects, which act as flux pinning centers. Ozkurt et al. [4] studied the effects of Nd3+ substitution for Pb2+ in dilute concentrations of Bi1.7Pb0.3−xNdxSr2Ca3Cu4O12+y (x=0.025, 0.050, 0.075, 0.1) compounds. The obtained results suggest that with increasing Nd3+ doping for Pb2+ the (2223) phase existing in undoped BSCCO gradually transforms into the (2212) phase and hence all of the samples have a mixed phase formation. The R-T result of the samples show two-step resistance transition; first transition occurs at 100 K and second in an interval of 80-90 K, depending on the Nd concentration. The magnetization decreases with increasing temperature in agreement with the general characteristic of the high-Tc materials.

The aim of this research is to investigate the effect of addition of Nd nanoparticles on the superconducting properties of Bi1.7Pb0.3Sr2Ca2Cu3O10+δ samples that prepared by solid-state reaction method.

Materials and Methods

Bi1.7Pb0.3Sr2Ca2Cu3O10+δ, bulk samples for x equals to (0.1, 0.2, 0.3, 0.4 0.5 and 0.6 were prepared by solid state reaction using appropriate weight of high purity powders (99.9)% of material Bi2O3, PbO, Sr (NO3)2, CaO, CuO, and nano powder Nd2O3 with particle size 50 nm for that proportional to their molecular weight. The powders were mixed together using agate mortar. A sufficient quantity of 2-propanol was added to form a paste during the process of grinding for about 1 h, to get a homogeneous mixture. Later the mixture was calcined in air at 800°C for 24 h. Then it was pressed into disk-shaped pellets 13 mm in diameter and 1 mm to 2 mm in thickness using a manual hydraulic press type (SPECAC) under pressure 0.7 GPa. The pellets were sintered in air at 835°C for 140 h. The prepared samples structure was obtained by using X-ray diffraction (XRD) (Philips). The critical temperature (Tc) determination and resistivity measurement achieved by using four-point probe method.

Results and Discussion

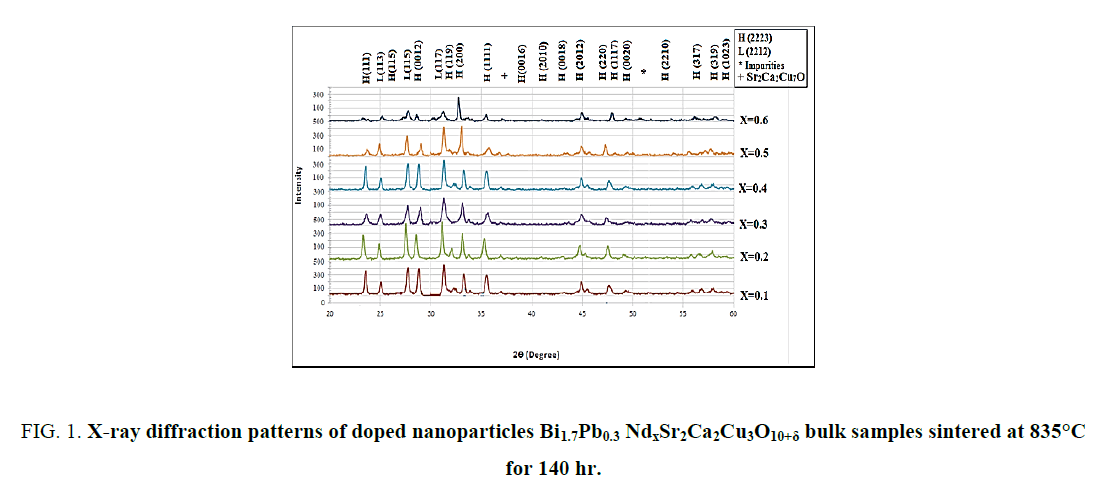

The crystal structure of Bi1.7Pb0.3Sr2Ca2Cu3O10+δ doped with Nd nanoparticles samples sintered at 835°C with different composition (x=0.1, 0.2, 0.3, 0.4, 0.5 and 0.6) were studied by XRD and represented in Figure. 1. The results of the X-ray diffraction patterns indicate that all samples had an orthorhombic structure with the presence of both phases; High-Tc phase (Bi-Pb)-2223, which was being the dominant phase, and low-Tc phase (Bi-Pb)-2212, and Sr2Ca2Cu7O as impurity phase of peak at 2θ=36.8° in some samples. Figure. 1 show some reflection lines, such as, H (220) vanished at x=0.6, H (2010) and H (0016) appeared at x=0.2 and 0.3, while H (111), H(0012) and H(119) decreased at x=0.6, but L(117) appeared at x=0.6. More over there is unsystematic variation in the growth of Bi-2223 as the percentage of Nd increases. In addition, no secondary phase has been observed which includes Nd ions. This shows that the Nd ions enter into the crystal structure of (Bi, Pb)-2223. Comparing the ionic radii of Ca+2 (1.06 Å) and Nd+3 (1.109 Å), the most probable occupancy of Nd ions is the Ca site in the crystal [3].

Table 1 shows a

Figure 1: X-ray diffraction patterns of doped nanoparticles Bi1.7Pb0.3Sr2Ca2Cu3O10+δ bulk samples sintered at 835°C for 140 hr.

decreasing of the lattice parameters a and c after x=0.2. Indeed, this behavior agreed with Aloysius et al. [3]. Moreover, increasing behavior of c parameters with Nd nanoparticles concentration could be interpreted as: heat treatment changes the oxygen content that is combination with added materials strongly altered superconducting properties, including increase of the super fluid density, which means Nd increases flux of the super fluid density.

| x | a (A°) | b (A°) | c (A°) | V(A°)3 | c/a | Tc (K) | Volume fraction of phases formed (%) | ||

|---|---|---|---|---|---|---|---|---|---|

| Bi-2223 phase | Bi-2212 phase | ||||||||

| 0.1 | 5.431 | 6.425 | 37.084 | 1294.015 | 6.828 | 0.669 | 111 | 78.571 | 21.428 |

| 0.2 | 5.450 | 5.442 | 37.172 | 1102.480 | 6.820 | 0.858 | 113 | 83.333 | 16.666 |

| 0.3 | 5.412 | 5.422 | 37.126 | 1089.420 | 6.859 | 0.814 | 111 | 76.923 | 23.076 |

| 0.4 | 5.376 | 5.350 | 37.115 | 1067.486 | 6.903 | 0.752 | 110 | 78.571 | 21.428 |

| 0.5 | 5.355 | 5.395 | 37.108 | 1072.058 | 6.929 | 0.458 | 110 | 75 | 25 |

| 0.6 | 5.358 | 5.304 | 36.905 | 1048.796 | 6.887 | 0.325 | 109 | 72.727 | 27.272 |

Table 1: Values of lattice parameters, volume of unit cell and Volume fraction of Bi-(2223) and Bi-(2212) at sintering temperature 835°C for different composition of Bi1.7Pb0.3Sr2Ca2Cu3O10+δ bulks.

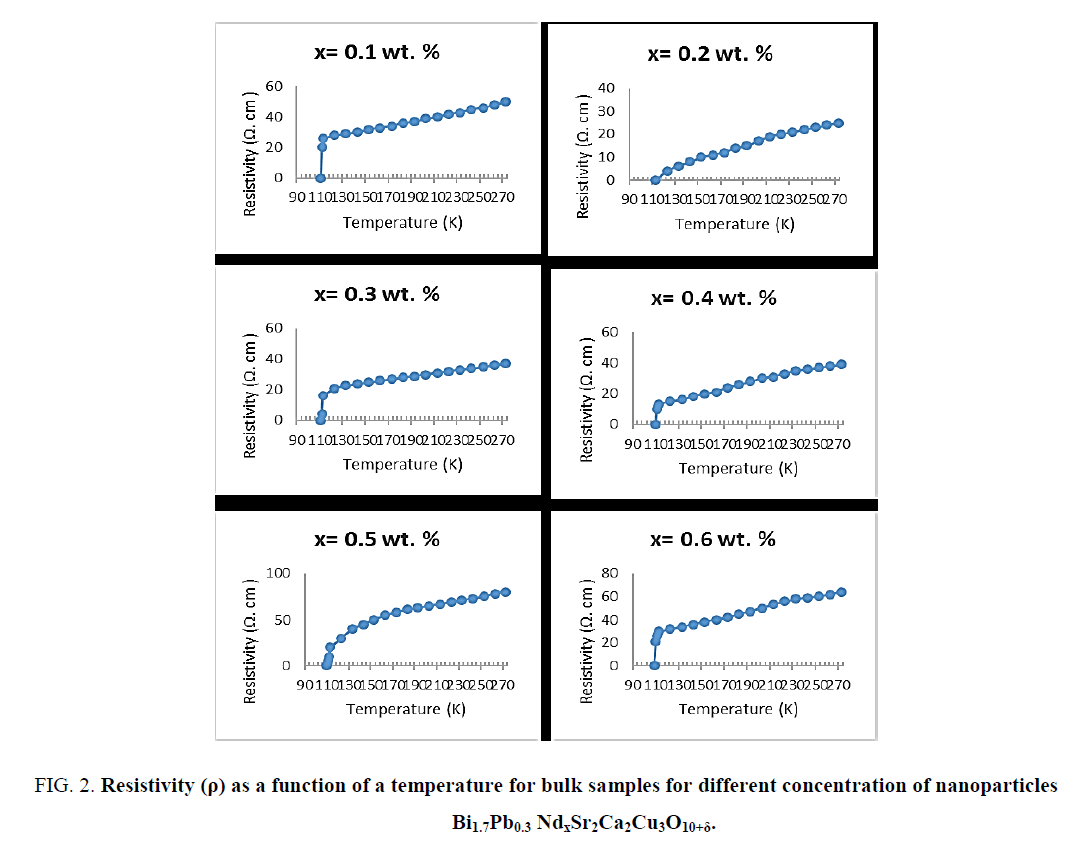

Figure. 2 shows the variation of resistivity with temperature for the samples of doping Bi1.7Pb0.3Sr2Ca2Cu3O10+δ. From the figure, all the compositions are superconductors with one-step transition although in all cases a complete zero-resistance could be observed. The higher Tc=113 K at ×=0.2 with. However, the enhancement of the Tc could be attributed to increase the contact between the grains and the growth of 2223-high Tc phase during the sintering process time. Moreover, this could characteristic to a decrease in oxygen content δ, leaves vacant sites. This may give rise to grain boundaries and act as poor contact within the 2223-phase. Such grain boundaries would occur at some stage as a crystallization decomposition process of the high-Tc phase at high sintering temperature.

Figure 2: Resistivity (ρ) as a funtion of a temperture for ulk samples for different concentration of nanoparticles Bi1.7Pb0.3Sr2Ca2Cu3O10+δ.

The addition of Pb2+ (1.19) in Bi3+ (0.96Å) sites is to release the internal stress [5], also the addition of Pb to the compounds may lower the modulation by influencing the charge balance, structural of the relevant layers [6].

The important argument which can be inferred from the results above, the addition of Pb on Bi sites and doping the nanoparticles with Nd in combination which specifies the improvement of links on intergranular interfaces of high temperature 2223-phases. The enhancement of Tc can achieve by appropriate amount of added nanoparticles in Bi-2223, which led to the improvement in electric connection between superconducting grains.

The results indicate the improvement of the samples, suggesting that a small amount of the doping acts as the effective pinning centers of the fluxes in the samples Nd nanoparticle doping more than 0.2 reduced the intergranular coupling and increased weak link behavior by increasing impurity phases, similar results mentioned by [7,8]. In addition, nanoparticle can fill the intergrain spaces, and thereby reinforce the coupling between granules. The decreasing of δ and Tc as nanoparticles Nd concentrations increasing from 0.3 wt% to 0.6 wt%. The explanation through the charge-ordering phenomenon, maybe induced by Pb and Nd as a pair breaker could be accompanied by changes in oxygen content or oxygen order effects that decrease the number of holes in the lattice from the optimum value [9]. The reason behind improving the Tc, the local structure of the BiO layer considered to be altering by increasing the amount of oxygen atoms. Therefore, the additional oxygen attracts electrons from the CuO plane, in that way, the creation of holes will shorten the Cu-O2 bond length [10,11]. In other hand, the decreasing of the average valance of Cu and the average CuO2-plane hole concentration in BiPb-2223 occurred by substitution by Pb. Therefore, the reduction of Tc was argued to be out of plane addition of Pb for Bi where it shows a longer wavelength of structural modulation [12].

Conclusions

XRD analyses presented the orthorhombic structure for all samples with two superconducting phases. The maximum transition temperature was 113 K with a higher volume fraction 83.3% of Bi-2223 and the maximum value of oxygen content was 0.858 which was found for the composition at x=0.2.

References

- Maeda H, Tanaka Y, Fukutomi M, et al. A new high-r oxide superconductor without a rare-earth element. J Appt Phys Pt. 1988;27:209-10.

- Chen SH. Effect of different nanoscale RE2BaCuO5 additions on the formation of compositional fluctuation in Sm-Ba-Cu-O superconducting bulk materials. J Mater Res. 2004;20:482-8.

- RP Aloysius, Enhanced critical current density in (Bi, Pb)-2223 superconductor by Nd addition in low percentages. Physica C. 2005;556-62.

- Ozkurt B. Structural and physical properties of Nd substituted Bismuth Cuprates Bi1.7 Pb0.3−xNdxSr2Ca3Cu4O12+y. J Low Temp Phys. 2007;149:105-18.

- Ikeda Y, Takano M, Hiroi Z, et al. The high-Tc with a new modulation mode in the Bi, Pb-Sr-Ca-Cu-O System, Japanese. J Appl Phys. 1988;27:L2067.

- Maeda H, Tagano K. Bismuth-based high temperature superconductors, Marcel Dekker, Inc., New York. 1996.

- Aloysius RP. Enhanced flux pinning in (Bi, Pb)-2223 superconductor by Nd addition, Supercond. Sci Technol. 2005;18:427-31.

- Hamid NA, ABD-Shukor R. Effects of TiO2 addition on the superconducting properties of Bi-Sr-Ca-Cu-O system. J Mater Sci. 2000;35:2325-9.

- Shatkovskis E, Dapkus L, Pyragas V. The metastable superior phases in Bi-2212 perovskite-like high-temperature superconductor, defects and surface-induced effects in advanced perovskites: NATO Sci Series. 2000;77:161-6.

- Abbas MM, Abass LK, Salman U. Influences of sintering time on the Tc of Bi2-xCuxPb0.3Sr2Ca2Cu3O10+δ high temperature superconductors. Energy Procedia. 2012;18:215-24.

- Khaled J, Komatsu T, Sato R. Formation and thermal stability of high-Tc phase in Te-Doped Bi-based superconducting glass-ceramics. J Ceram Soci Japan. 1997;105:279-83.

- Salamati H, Morshedloo T, Kameli P. The effect of Ba substitution at Sr site in Bi-2223 high-Tc superconductors, Iranian Journal of Physics Research, Proceedings of the Second National Conference on Advances in Superconductivity 2010;10:34.