Original Article

, Volume: 16( 1)Study on Structural Properties of Concrete by Partial Replacement of Fly Ash and Quarry Dust

- *Correspondence:

- Vetriselvan M, Ph.D Scholar, Department of Civil Engineering, Periyar Maniammai University, Vallam, Tamilnadu, India, Tel: 04362264600; E-mail: vmvetriselvan11@gmail.com

Received: November 22, 2017; Accepted: December 26, 2017; Published: January 02, 2018

Citation: Vetriselvan M, Sentamilkumar S. Study on Structural Properties of Concrete by Partial Replacement of Fly Ash and Quarry Dust. Int J Chem Sci. 2018;16(1):232

Abstract

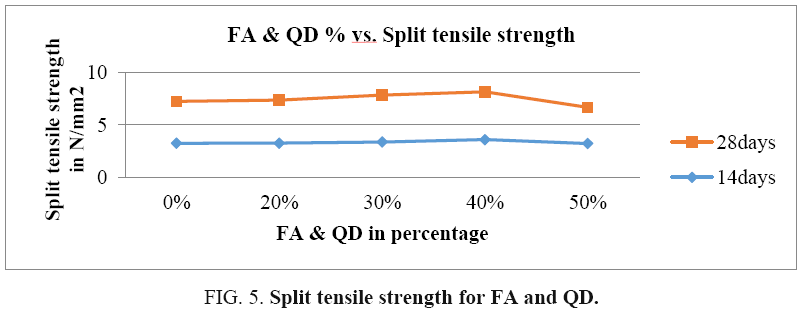

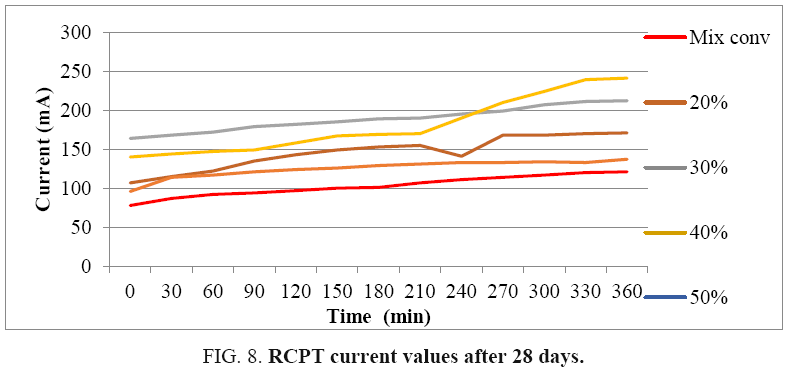

This research study presents the strength variations of concrete when replacing fine aggregate by quarry dust and cement by fly ash from 0%, 20%, 30%, 40% and 50% in step by step. For this study M25 grade of concrete are used. The experimental study of compressive strength of fly ash concrete cubes at age of 7, 14 and 28 days are taken at room temperature. Also, the split tensile strength of fly ash concrete cylinders was found at the age of 14 and 28 days. The flexural strength of the concrete beams is cured by water at 28 days. Following that the admixture of casein protein was added in fly ash and quarry dust concrete specimens while casting process. In this study the advanced method of chloride penetration method (RCPT) was conducted for the fly ash and quarry dust concrete. Finally, this study shows the structural properties like compressive strength, split tensile strength and flexural strength of fly ash and quarry dust concrete at various percentage of replacements and also describes the advanced testing of chloride permeability of concrete at 0% to 50% replacement of fly ash and quarry dust.

Keywords

Fly ash; Quarry dust; RCPT; Compressive strength

Introduction

Concrete is a most important material in construction field. Concretes are the composite materials and its composites of coarse aggregate, fine aggregate and bonded with cement. In concrete the Portland cements is most common material in general usage of concrete. Now a day’s the requirements of construction materials are high so that the lagging of cements and other raw materials are high. To avoid this type of problems in constructions means to improve the usage of alternative construction materials in construction fields.

Fly ash is the most common and well known alternative material in concrete. Fly ash is a coal combustion product and it’s composed of fine particles from the boiler with fuel gases [1-4]. These are the substitute material for the portland cement. Fly ash improves the workability and reduces the greenhouse gases. It will applicable for concrete structures and also the brick works, wall constructions etc.

Quarry dust consists of finely crushed rocks. This is also one of the alternative materials in construction side. It should be used as a fine aggregate in a concrete [5-7]. These are partially replaced at certain percentages in concrete. It will act as a filler material. Quarry dusts are additionally or partially added into the concrete means it will improve the quality of concrete and also to improve the workability of concrete (Figure 1-9). It won’t affect the properties of conventional concrete [8,9]. If fly ash and quarry dusts are partially replaced in concrete up to 50% means it improve the strength of the fly ash concrete and also this is one of the way to detect the problems placed in construction side lack of raw materials (Tables 1-8).

| Property | Experimental Results |

|---|---|

| Fineness of Cement | 10% |

| Specific Gravity of Cement | 3.25 |

| Initial setting time | 31.30 Minutes |

| Final setting time | 650 Minutes |

| Standard consistency | 31% |

| Specific Gravity of Fly ash | 2.81 |

| Specific Gravity of Fine aggregate | 2.7 |

| Specific Gravity of Quarry dust | 2.65 |

Table 1: Properties of materials.

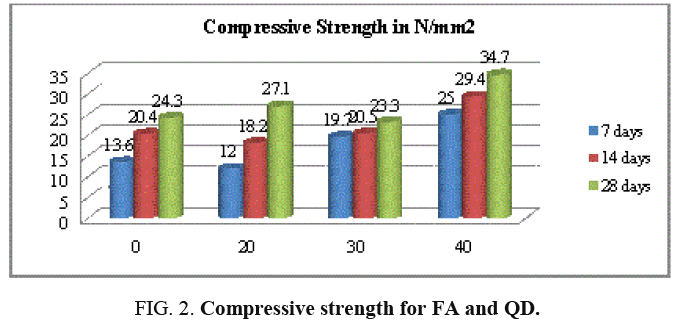

| %ofFA & QD | Compressive strength in N/mm2 | ||

|---|---|---|---|

| 7 th day | 14 th day | 28 thday | |

| 0 | 13.6 | 20.4 | 24.3 |

| 20 | 12 | 18.2 | 27.1 |

| 30 | 19.7 | 20.5 | 23.3 |

| 40 | 25 | 29.4 | 34.7 |

| 50 | 21.9 | 34.6 | 40.3 |

Table 2: Compressive strength of FA and QD cubes.

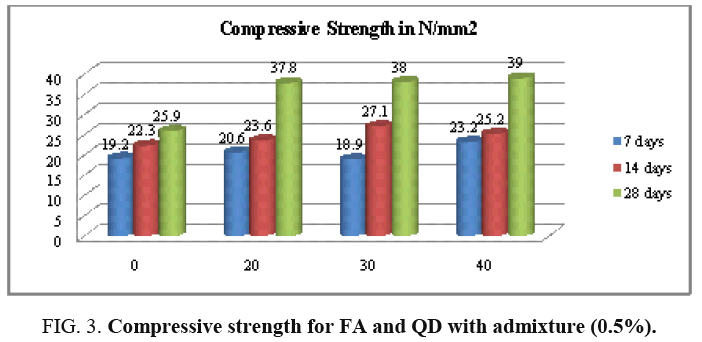

| %ofFA & QD | Proteins % | Compressive strength in N/mm2 | ||

|---|---|---|---|---|

| 7 th day | 14 th day | 28 thday | ||

| 0 | 0.5 | 19.2 | 22.3 | 25.9 |

| 20 | 0.5 | 20.6 | 23.6 | 37.8 |

| 30 | 0.5 | 18.9 | 27.1 | 38 |

| 40 | 0.5 | 23.2 | 25.2 | 39 |

| 50 | 0.5 | 19.5 | 30.1 | 42.3 |

Table 3: Compressive strength of FA and QD cubes with admixture.

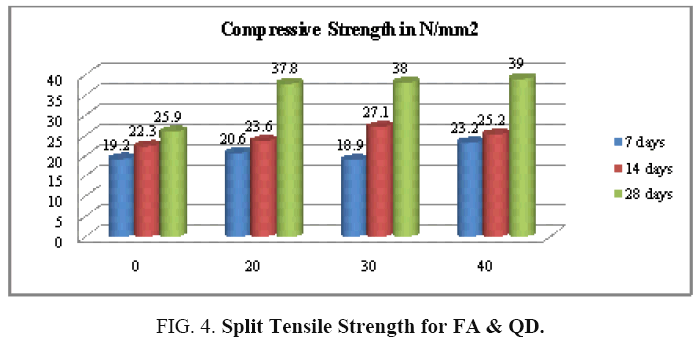

| %of FA & QD |

Curingdays | Split tensile strength(N/mm2) | ||

|---|---|---|---|---|

| 14days | 28days | 14 days | 28days | |

| 0 | 179 | 197 | 2.39 | 2.69 |

| 20 | 148 | 201 | 2.06 | 2.8 |

| 30 | 169 | 210 | 2.39 | 2.91 |

| 40 | 161 | 220 | 2.23 | 3.09 |

| 50 | 193 | 237 | 2.72 | 3.31 |

Table 4: Split tensile strength of FA & QD specimen.

| %of FA & QD with admixture |

Curingdays | Split tensile strength(N/mm2) | ||

|---|---|---|---|---|

| 14days | 28days | 14 days | 28days | |

| 0 | 235 | 286 | 3.27 | 3.97 |

| 20 | 229 | 291 | 3.28 | 4.08 |

| 30 | 243 | 318 | 3.39 | 4,45 |

| 40 | 257 | 323 | 3.61 | 4.53 |

| 50 | 199 | 247 | 3.24 | 3.42 |

Table 5: Split tensile strength of FA and QD specimen with admixture.

| %of FA & QD |

Load(KN) | Flexural Strength (N/mm2) | ||

|---|---|---|---|---|

| Trial 1 | Trial 2 | Trial 3 | ||

| 0 | 12 | 10 | 11 | 4.4 |

| 20 | 16 | 12 | 14 | 5.6 |

| 30 | 15 | 17 | 16 | 6.4 |

| 40 | 13 | 16 | 14.5 | 5.8 |

| 50 | 14 | 17 | 15.5 | 6.2 |

Table 6: Flexural strength of FA and QD beam.

| Time (min) |

Current valuesin mA | ||||

|---|---|---|---|---|---|

| 0% | 20% | 30% | 40% | 50% | |

| 0 | 78 | 107 | 96 | 164 | 140 |

| 30 | 87 | 115 | 114 | 168 | 144 |

| 60 | 92 | 122 | 117 | 172 | 147 |

| 90 | 94 | 135 | 121 | 179 | 149 |

| 120 | 97 | 143 | 124 | 182 | 158 |

| 150 | 100 | 149 | 126 | 185 | 167 |

| 180 | 101 | 153 | 129 | 189 | 169 |

| 210 | 107 | 155 | 131 | 190 | 170 |

| 240 | 111 | 141 | 133 | 195 | 190 |

| 270 | 114 | 168 | 133 | 199 | 210 |

| 300 | 117 | 168 | 134 | 207 | 224 |

| 330 | 120 | 170 | 133 | 211 | 239 |

| 360 | 121 | 171 | 137 | 212 | 241 |

Table 7: RCPT current values after 28 days.

| Mix | Charge flow (Q) in Coulomb (C) |

|---|---|

| Mix CON | 2231.1 |

| 20% | 3883.5 |

| 30% | 1881.9 |

| 40% | 4823.1 |

| 50% | 4030.2 |

Table 8: RCPT charge flow (Q) in coulomb (C) through the concrete specimen after 28 days.

Material and Methods

Super plasticizer

Casein protein: In this work casein protein was added to the concrete to reduce water cement ratio this increases durability of concrete.

Conclusions

• From the results the compressive strength of the fly ash and quarry dust concretes are high compare to conventional concrete

• The strength should be increase up to more than 65%.

• The maximum compressive strength was obtained at the 50% replacement of FA and QD.

• The split tensile strength should be increase up to more than 46%

• The maximum Tensile strength was obtained at the 50% replacement of FA and QD and 40% while adding the admixture.

• The percentage increase in flexural strength is 17.54% when compared with conventional concrete.

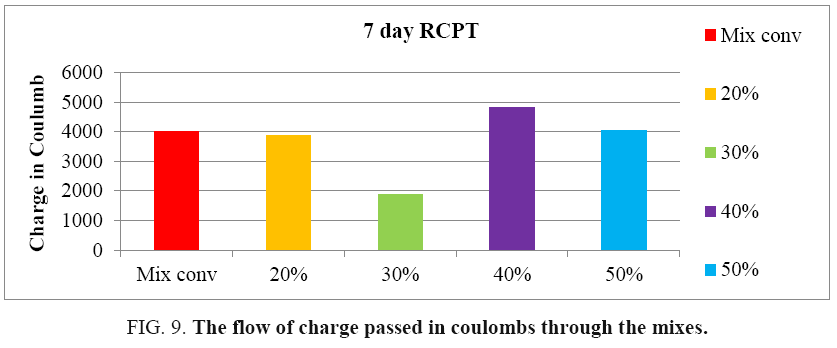

• In RCPT test the minimum charge flow obtained at 30% replacement of cement and fine aggregate.

• Maximum charge flow obtained the fly ash specimen was 4823.1 at 40% of replacement.

References

- MalathyR, GovindaswamyT. Strength development of various grades of self-compacting concrete with flyash.Asian J Chem.2005.

- Kumar V, Prasad MM. Effect of flyash and silica fume on the static modulus of elasticity of a concrete mix. NatIns Technol. 1990.

- AndalL,PalanichamyMS,SekarM. Durability of polymer and flyash modified ferrocement elements.Procedia Eng.2007.

- Song PS, Hwang S. Mechanical properties of high-strength steel fiber-reinforced concrete. Construction and Building Mat. 2004;18(9):669-73.

- Hwan B. Flexural analysis of reinforced concrete beams containing steel fibers.J Struct Eng.1992.

- Walraven JC. High performance fiber reinforced concrete: Progress in knowledge and design codes.Mat and Struct.2009.

- Gencoglu M, Mobasher B. Monotonic and cyclic flexural behavior of plain concrete beams strengthened by fabric-cement based composites. In: Proc. 3rd International Conference on Structural Engineering. Mech and Comp. 2007;pp:1961-6.

- Ministry of Transportation Kingdom of Saudi Arabia. Guideline for Application and Use of High Performance Concrete. 2010.

- Alonzo O, Barringer WL, Barton SG, et al. Guide for selecting proportions for high-strength concrete with Portland cement and fly ash. ACI Mater J. 1993;90(3):272-83.