Original Article

, Volume: 7( 2)Review of Design Strategies and Benefits for Electronic Assemblies Operating

- *Correspondence:

- José A. Carrasco, Embedded Instruments and Systems, EMXYS, Avda. de la Universidad sn, 03202 Elche, Spain, Tel: 966442304; Fax: 96665882, E-Mail: jacarrasco@umh.es

Received: May 30, 2018; Accepted: June 08, 2018; Published: June 12, 2018

Citation: Carrasco JA, Quirós FG, Alavés H, et al. Review of design strategies and benefits for electronic assemblies operating at low temperatures in space applications. J Space Explor. 2018;7(2):145

Abstract

The workings of electronics at low temperature have many potential advantages since, up to a certain level of integration, reduce losses and increase the speed of electronic circuitry. Besides cryogenic applications used for scientific and medical purposes, the operation of circuits at low temperatures has been proposed in the past to increase general electronic system performance to be abandoned later by the fast technological increase in performance of modern electronic devices. The objectives of the present paper are to review the recommendations or modifications to make possible electronic designs, including implementation aspects that work at low temperature and severe thermal environment while being compliant with present manufacturing standards for space applications. The recommendations may involve materials selection, operation over the PCBs (soldering), storage and the operation of electronics at low temperatures and wide thermal cycles.

Keywords

Low temperature electronics; Solderability; PCB; Cryogenics

Introduction

Traditionally, low temperature electronics for space applications has had as main target the implementation of sensors and measuring devices, and its associated front end, to decrease electronic noise or for the need of sensing objects radiating at very low temperatures [1]. However, the operation of usual spacecraft systems at low temperature might have extra advantages such us reducing the thermal control system, increasing electronics performance and reducing volume and ultimately cost [2] of the spacecraft and launch operations providing more flexibility to deep space probes.

As an example of control system whose implementations could be relaxed we may cite the New Horizons probe, that has already visited Pluto, that makes use of the heat of a chunk of plutonium and a thermal control system that includes a shield of thermal blankets to keep an internal temperature at around 20°C from an external temperature of -200°C [3]. Other probes, such as XMM-Newton, rely on an intelligent thermal design to maintain an average temperature within the service module above 0°C [4].

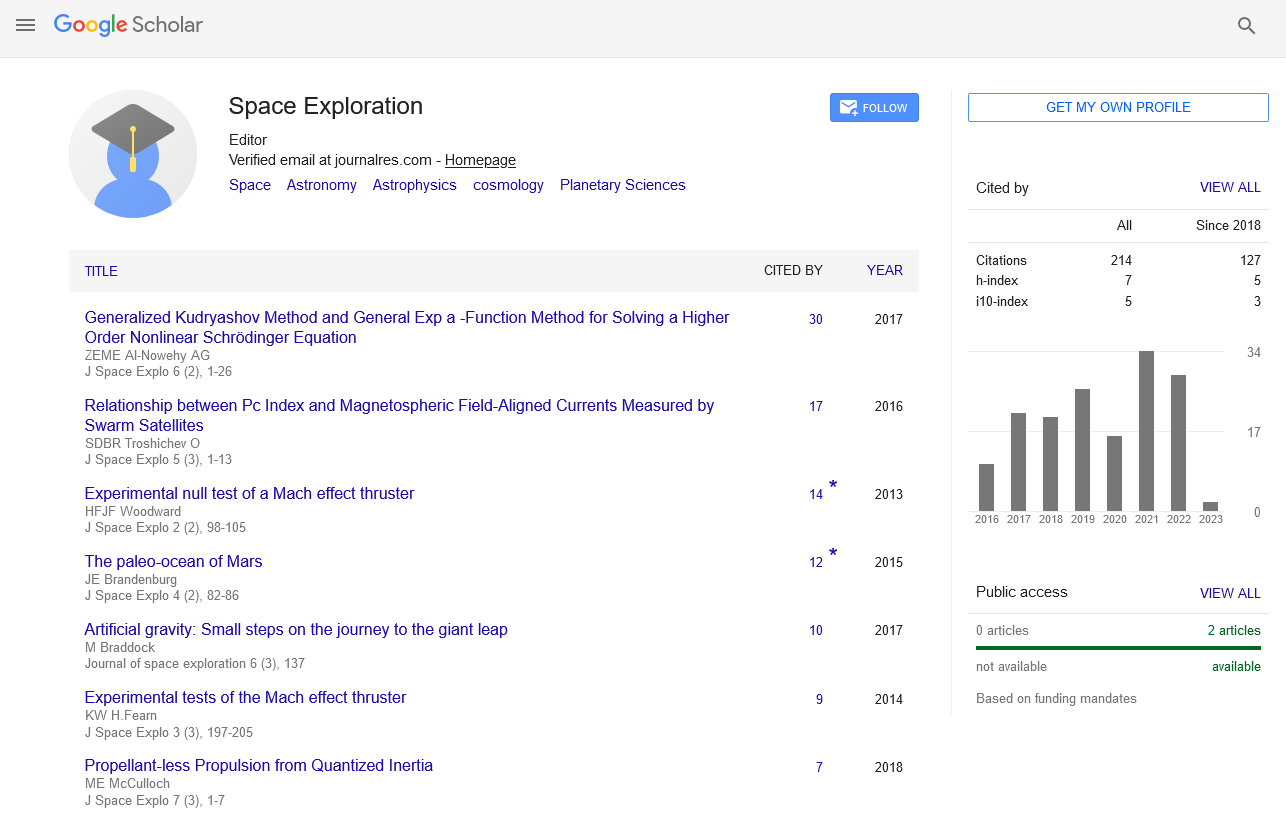

FIG. 1 shows the environment temperatures as a function of the distance to the Sun for deep space probes with reference to its surface painting.

Figure 1: Environment temperatures for deep space spacecraft as a function of its distance to the Sun.

Method

Low temperature working of electronic circuits

The operation of an electronic system at low temperature and its ability to withstand high amplitude thermal cycling involves three different actuation scenarios:

1. Understanding the working of electronic components at low temperatures and progressing it to the implementation of the circuit and evaluate its behaviour at low temperatures or temperature cycling.

2. Mounting of components onto the PCB by having into account the mechanical stresses acting upon them as a consequence of the different coefficient of expansion of the different materials involved in the solder joint, die gluing or packaging fixing to the PCB.

3. Consideration of a conformal coating with mechanical properties and CTE suitable for the severe thermal cycling based on [5] and taking into account current studies [6].

4. Consideration of a conformal coating with mechanical properties and CTE suitable for the severe thermal cycling based on [7] and taking into account current studies [8].

The three scenarios are, in what follows, analysed separately. For the electric characteristics we address each of the main electrical, electronic and electro-mechanical components with the impact its parametric variation may produce in a relevant circuit application.

Resistances and capacitors change following its temperature coefficients when their working temperature is lowered although its nominal value or intrinsic (parasitic) characteristics may experiment different variations, such as the nominal value, TCR and VCR for resistors [9] or the nominal value, ESR, leakage currents and breakdown voltages for capacitors [10]. TABLE 1 shows circuit applications where resistances are applied and the effect of the part variation over the working of the circuit. TABLE 2 lists the same for capacitors.

| Circuit | Effect of resistor parameter drift on subsystem working |

|---|---|

| Current limitation | Change of maximum limitation current |

| Divider circuit | Change in dividing factor |

| Polarisation circuits | Change in polarisation voltage |

| Filters | Change in cut-off frequency |

| Change of bandwidth | |

| Change of quality factor of filter | |

| Amplifiers | Change in gain |

| Comparators | Change in comparing threshold of comparing voltages |

| Change on comparison window |

Table 1: Some examples of circuits where resistors are used and the effect of resistor variation over the subsystem functioning.

| Circuit | Effect of capacitor parameter drift on subsystem working |

|---|---|

| Filters | Change in cut-off frequency |

| Change of bandwidth | |

| Change of quality factor of filter | |

| Decoupling | Affect EMC or EMI of the circuit |

| PID amplifiers | Subsystem stability parameters or conditions changed because of change of proportional, integration or derivative constant. |

| Oscillators | Change in oscillation frequency |

Table 2: Some example circuits where capacitors are used and the effect of parameters variation over the subsystem functioning.

Diodes at low temperature change its operation by providing higher forward voltages [11], and therefore increasing forward conduction losses [12]. For switching diodes, such as the ones used in switched power supplies, the reverse current and commutation times decrease considerably [13] thus compensating somehow the increase in forward drop. Zener diodes, for use as shunt regulators, present quite different behaviour depending on the selected model, ranging from voltages that change in tens of millivolts to several hundred millivolts [14].

Bipolar transistors are part of the circuits listed in TABLE 3 as an example. Their behaviour when lowering its nominal temperature makes them practically unusable, though its decrease in collector-base breakdown voltage is compensated by an increase in its collector-emitter breakdown voltage [15], the decrease in current gain is very notable [16]. However, bipolar technology variations such us SiGe HBT offers several advantages al low temperatures [1] and may be combined (to manufacture ICs) with CMOS technologies (Bi-MOS) for low temperature operation.

| Circuit | Effect of bipolar transistors parameter drift on subsystem working |

|---|---|

| Amplifiers | Probably no effect, if drift is small, because amplifiers are designed not to depend on transistor parameters |

| Current sensors | Probably no effect, if drifts are small, since current sensor is designed not to rely on transistor parameters |

| Drivers | Change of driving capability |

| Protection circuits | Probably small or no effect because use of the circuit inside feedback systems |

| Majority voters | Probably small or no effect because use of the circuit inside feedback systems |

| Oscillators | Frequency change |

| Change of quality factor (Q) | |

| Biestable/monostable circuits and discrete logic circuits. | Probably small unless circuit relies on identified parameters |

| Change of threshold values |

Table 3: Main circuits where bipolar transistors are used and the effect of parameter variation over the subsystem functioning.

MOSFET transistors characteristics benefit at low temperature operation up to a point that low temperature operation has been suggested many times, in the past, for improving the performances of analog and digital circuits based on them. Reduction of leakage currents, increase in electrical conductivity (lower RDSON and reduced conduction losses) and thermal conductivity (better heat removal) and dramatic decrease in switching times (reduced switching losses) are among the enhanced features [17] as long as the channel length is not reduced beyond a certain point (less than 0.1 mm) in which parasitic effects, corresponding to carrier mobility and saturation velocity, that do not scale with size prevail [1]. TABLE 4 summarizes typical applications of MOSFET transistors within the space environment and the effect for the circuit of changing MOSFET parameters.

| Circuit | Effect of MOSFET transistors parameter drift on subsystem working |

|---|---|

| Amplifiers | Probably no effect, if drift is small, because amplifiers are designed not to depend on transistor parameters |

| Switching circuits | Change of switching characteristics: switching time, current driving capability |

| Protection circuits | Probably small or no effect because circuit is designed not to rely on component characteristics |

| Oscillators | Frequency change |

| Change of quality factor (Q) | |

| Biestable/monostable circuits and discrete logic circuits. | Probably small unless circuit relies on identified parameters |

| Change of threshold values |

Table 4: Example circuits where MOSFET transistors are used and the effect of parameter variation over the subsystem functioning.

The characteristics of complex ICs based on MOSFET and Bi-MOS transistors are extrapolated from the characteristics of the individual elements, as it is not feasible to model the low temperature operation of complete ICs used in space applications by having into account its individual components, being the lack of models for the technologies the main reason. For high scale of integration circuits, the small individual device dimensions, increases the avalanche breakdown, reduce latch up and kink effects, as well as the hot carrier degradation, all leading to reliability reduction of the devices, see chapter 3 of [1]. The quantification of these effects for analog and digital ICs are therefore individually modelled and quantized experimentally under controlled laboratory setups.

It is possible to find literature references to many analog and digital integrated circuits working at low temperatures and we may find examples of any families we may think of. Moreover, examples of these ICs implementing full circuits are found as well. As examples of full circuits, representative of space applications, we may cite:

1. Studies the behavior of PWM controllers, both bipolar and CMOS based technologies, at low temperature, verifying reduced leakage currents and latch-up susceptibility and increase of speed, that added to increased carrier mobility of the MOSFET power transistors slightly increases the efficiency of power converters. Synchronous rectification may be needed as well to avoid the negative effects of diodes at low temperature, already described, and have an efficiency increase [16].

2. Due to the importance of the component, many examples exist on operational amplifiers characterisation, we cite [18] as example.

3. Shows the ability of a SAR ADC to function properly and at a reasonable speed of 5 Msps when cooled down to -230°C. [18]

4. External voltage references may be needed when the behaviour of the IC depends on pretty well-regulated voltages such us ADC or PWMs [Error! Reference source not found.].

In this case the voltage reference IC may be characterized at the operation temperature or temperatures to guarantee minimum variations [14].

5. Ray et al.[12] implemented a DC/DC converter that works at 77 k studies the working of Molypermalloy Powder Cores (MPC) at very low temperature and [19] extends the study to High Flux Cores (HFC) and Kool Mu Cores (KMC). The results find that losses due to the magnetic core remain the same when compared to usual temperature operation since the expected winding loss decrease is compensated by increase eddy-current core loss due to increase of core resistivity.

6. Memories [20], logic circuits based on CMOS [21] and Bi-MOS technologies and microprocessors have been studied as well. In fact, computers working at cryogenic temperatures were employed back in the 80s [1].

These studies not only characterize the behavior of present circuits, but present as well design directives for future designs to be made specifically for low temperature (and cryogenic temperature) some that goes beyond our brief study. FPGAs for space have also been tested at low temperatures [22].

7. Even the possibility of using optocouplers [23], and under a wide temperature range, is shown in the literature.

8. We have not found however the use of relays, a clear player of electromechanical component, at low temperatures. Even a reference in this subject such as [24] does not give reference applications of this component.

Further, fuses, due to its particular material characteristics and critical protection applications need to be manufactured specifically to suit low temperature needs.

Tables showing the influence of parametric drifts in circuits that implement magnetic cores and amplifiers are shown in TABLE 5 and 6.

| Circuit | Effect of inductor/transformer parameter drift on subsystem working |

|---|---|

| Power supplies | Change in energy storage properties that will lead to increment of audiosusceptibility, EMC/EMI, output ripple, losses increase |

| Filters | Change in bandwidth and attenuation performance |

| Signal transmission/Galvanic isolation | Probably small or no effect since no currents are involved |

| Impedance adapters | Increase of losses |

Table 5: Effect of inductor/transformer parameter drift on circuit functioning.

| Circuit | Effect of amplifier parameter drift on subsystem working |

|---|---|

| Amplifiers | Change in gain, offset and bandwidth |

| Change of response to common mode | |

| Change on power consumption | |

| Filters | Change in bandwidth and attenuation performance |

| I/V and F/V converter | Gain change (that is translated to change in characteristic curve of device) |

| Majority voter | Probably none if drift is small because this circuit is part of a feedback loop |

| ADC & DAC converter | Conversion error (increase in number of bits of error) |

| Signal processor | Variation of processing characteristics |

Table 6: Effect of operational amplifier parameter drift on circuit functioning.

Other works study the functioning of complete circuits and even the behaviour of Commercial Off-the-Shelf (COTS) components encapsulated under standard packages for evaluation of future space missions. [25] implements several circuits for testing COTS oscillators, and other elements such as passive components and MOSFETs, in a standard PCB and presents tests at low temperature for application in a Mars surface mission. Ray et al. [13] presents low temperature measurements for a (spacializable) DC/DC converter prototype and [26] makes the study for commercially available DC/DC converters.

Finally, the complete reference [1] presents much more examples.

The prediction of circuit functioning at very low temperatures is not straightforward since there is a lack of models of the different parts commercially available, whose data is provided by manufacturers to a minimum of -55°C, if the component has not been conceived specifically for low temperature operations. Simulation is not reduced to decreasing the working temperature in a standard (SPICE based for example) simulator as [27] describes, but a new redefinition of the modelling equations to account for new effects are to be introduced in the simulator.

There is even a BSIM SPICE based circuit simulator software that performs simulations at low temperature by taking into account the new parts behaviour [28]. FIG. 2 presents a simulation of a Buck DC/DC converter running at -100°C in CoolSpice, the simulator specially tailored for low temperature simulations; the MOSFET and Diode models used in the simulation are obtained having into account the physical characteristics of the devices (diffusion lengths) and do not exist as commercially available components.

It is apparent that the operation of components not initially conceived to operate nominally at temperatures below -55°C and, even, worse to withstand thermal cycling of temperatures down to -100°C will alter its reliability characteristics. Component reliability has to be evaluated in a case-by-case basis, although effort to set a reference framework from where to interpolate reliability predictions has been made by several authors. Chen et al. [29] gave a reference paper of the impact of cycles at low temperature, on hot carrier aging degradation, for a Mission on the surface of Mars. Other works address this degradation thought with more limited temperature excursions [30].

Implementation of electronic circuits working at low temperatures.

But the real concern that arise when dealing with very low temperatures, and with temperature excursion cycles than reach very low values, is the mechanical attachment of the different elements that form the PCB, i.e. the mechanical issues that arise at microscopic level.

Exhaustive studies have been made by the European Space Agency [31-32] in the past to obtain data related to PCB materials procurement and manufacturing, soldering of components and repairing, see European Cooperation for Space Standardization ECCS website for documents ECSS-Q-ST-70-71C, ECSS-Q-ST-70-08C, ECSS-Q-ST-70-38C.

As a general rule, component stand-off and stress relief at the leads of the component (between the solder joint and its body) should be enough to deal effectively with the different coefficients of thermal expansion (CTE) that appear at PCB level.

When handling lead components of small size it is relatively easy to comply with stress relief techniques. However, problems arise when dealing with modern SMT packages, especially when they are big and with leadless chip carriers. Further problems may arise at the interior of packages due to the inner mounting of the die itself within the package and different CTEs between them.

The first issue to have in mind when soldering SMT components is that solder is the only load-bearing member: It must absorb stresses as well as to provide electrical connections. Having also in mind that mechanical shocks and vibrations (studied under simulated launch environments) have little effect on the quality of solder joints, it is the result of several studies [-32], that the main cause of solder joins failures is thermal fatigue, which occurs under big thermal cycles and is accentuated if low temperatures are reached.

Further, repeated studies show that solder joints are unlikely to fail because its tensile strength is slightly exceeded in a single thermal cycle, but it is more likely caused by an accumulation of relative large cyclic strains, due to different CTEs of the materials that form the joint. Much effort has also been made in determining the best solder alloy to get the highest reliability of the metallurgical union created between the PCB and electronic component (with the solder in between) [33].

Many experiences have identified as a high reliable solder joint, from the point of intermetallic joints, those using Pb63Sn37 (even with small quantities of other metals such as silver) and the removal of gold plated leads with a pure-tin plus a pre-tin bath before soldering. Moreover, to the use of other alloys, such as Sn62 silver loaded alloys to decrease scavenging of components with silver surfaces (see ECSS-Q-ST-70-08C) as widely known

All these techniques work well at temperatures, within space environment, far over the -100°C. In order to improve reliability of the soldering other solder alloys could be investigated, as an example Pb97.5Ag1.5Sn1 alloys are suggested for use at low temperatures for general operations, and Indium based allows, that form very ductile intermetallic compounds, as a very good candidate in soldering, gold plated, RF components [-32].

A first rule of thumb for SMT components would be to select this as small as possible to experiment the less variation in its size when cycling (therefore 0603 SMT components are preferred over 2010 ones).

In case this is not possible alternative mounting techniques for components may be implemented, see Fig. 3 for an example of leaded component and [34] for an example of leadless components. If techniques as those described in ECSS-Q-ST-70-38C are used it has been shown that high reliabilities are obtained if the solder fillets are of equal size at all the joints of the components (and specially if it is a component with two joints as a resistor or capacitor) and if a suitable stand-off is implemented; In particular the highest the stand-off the bigger the number of life cycles under severe thermal cycling [35] and stand-offs up to 0.4mm, or even bigger (conflicting with ECSS-Q-ST-70-38C) may be desirable.

Figure 3: Modification of interconnection design of leaded component to ensure absence of thermal fatigue under severe thermal cycling.

Wires pose another field of concern while operating at low temperatures since a proper wire needs to have both good solderability and proper insulation. Tin-plated and silver-plated wires are found to perform well when soldered at low temperatures in space environment. On other side Kapton and Gore-tex insulators have proven to be flexible and perform well at thermal cycling and low temperature operation [36].

And last, proper glues will need to be identified to: Paste big components to the PCB to encapsulate component dies within an appropriate packaging to withstand thermal cycling. At this point there are, as well, very good candidates with space heritage that we may find commercially available [37].

If COTS components are to be selected it is important that the terminations or lead materials are not finished with pure tin. Lead-free (Pb-free) terminations are popular with COTS devices for commercial electronics, but at very low temperatures (like those considered in this study) pure tin can change from a bright metal to a grey powder: known as tin-pest. Also, pure tin can form small whiskers that are known to cause short-circuits.

For this reason, we propose to analyse the surfaces of all COTS devices and when pure tin is detected the terminations will be dipped into tin-lead eutectic solder pots at 200°C as prescribed in ECSS-Q-ST-70-08. When using leadfree solders futher analysis are needed as studied in research by Vandevelde et al. [38].

About materials that form the PCB, in general, space PCBs are fabricated from polyimide-glass (CTE 12 - 16 ppm) or epoxy-glass such as FR4 with a CTE of 14 - 18 ppm. These CTE's are far larger than the ceramic packages of some components (6 - 8 ppm).

Some low expansion PCB substrate materials do exist, such as Stablecore (made by Elmatica) but this has not yet been space-qualified. Thermount substrates were space-qualified (this has a CTE of 5 - 8 ppm and was made of aramid fibres in a polyimide matrix) but this product is unfortunately no longer produced. High reliability testing of PCBs is of maximum importance to qualify space grade materials [39].

Conclusion

The working of electronic circuits at low temperatures may lead to improved features, such as better speeds or bandwidth, lower losses and even mass and volume reductions when working in very low temperature environments. Far from being an inconvenience, very low temperatures may combine enhanced working of the electronics while avoiding the increase in mass and volume involved in encasing the systems in a temperature controlled environment.

Not only deep space missions may benefit from this but also telecommunication satellites orbiting around Earth for which a small savings in any subsystem has a big impact in cost.

However, the working of electronics at very low temperatures requires careful consideration of many aspects given for granted in present electronics designs. This paper has pointed out these considerations.

References

- Gutierrez D, Edmundo A, Jamal M, et al. Low Temperature Electronics Physics, Devices, Circuits, and Applications. Elsevier 2010.

- Patterson, R, Hammoud A, Elbuluk M. Electronics for Low Temperature Space Explorations Missions. Abstract for the International Microelectronics and Packaging Society (IMAPS), 2nd Advanced Technology Workshop on Reliability of Advanced Electronic Packages and Devices in Extreme Cold Environments. 2007.

- Battersby S. Welcome to the Planet that Was. New Scientist No. 3025. 2015:28-33.

- Fortescue P, Swinerd G, Stark J. Spacecraft Systems Engineering. 2011.

- Fink M, Fabing T, Scheerer M, et al. Measurement of mechanical properties of electronic materials at temperatures down to 4.2 K. Cryogenics. 2008;48:497-510.

- Dunn B. Evaluation of conformal coatings for future spacecraft applications. 1995.

- Zandman F, Simon P, Szwarc J. Resistor Theory and Technology. Scitech Publishing. 2002.

- Teverovsky A. Effect of Temperature Cycling and Exposure to Extreme Temperatures on Reliability of Solid Tantalum Capacitors. NASA Electronic Parts and Packaging (NEPP) Program. 2007.

- Patterson R, Hammoud A, Elbuluk M, et al. Performance of Various Types of Diodes at Cryogenic Temperatures. NASA Electronic Parts and Packaging Program. 2004.

- Ray B, Gerber, S, Patterson R, Myers I. The 77 K operation of a multi-resonant power converter. NASA-TM-106941. 1995.

- Ray B, Gerber S, Patterson R, Myers I. Low-temperature operation of a Buck DC/DC converter. Applied Power Electronics Conference and Exposition. 1995.

- Basit W, El-Ghanam S, El–Maksood A, Soliman F. Performance of shunt voltage regulators based on Zener diodes at cryogenic temperatures. Physical Sciences Research International. 2013;1:16-24.

- Singh R, Baliga B. Cryogenic operation of power bipolar transistors. Solid-State Electronics. 1996.

- Lengeler B. Semiconductor devices suitable for use in cryogenic environments. Cryogenics. 1974;14:439-447

- Gaensslen F, Rideout V, Walker E, Walker J. Very small MOSFETʼs for low-temperature operation. IEEE Transactions on Electron Devices. 1977;24.

- Elbuluk, M, Gerber S, Harnmoud A, Patterson R, Newell M. Low temperature evaluation of bipolar and CMOS-based current-mode PWM controllers. Industrial Electronics Society, IEEE 2002 28th Annual Conference of the IECON 02. 2002;1:456-461.

- Gago F, Diaz J, Garzon F, Patron J. Characterization of the OPA350 Operational Amplifier at Cryogenic Temperatures. Scientific detectors for astronomy. 2006;336:645-650.

- Yao Y. Design and Implementation of High-Speed Low-Power Analog-to-Digital and Digital-to-Analog Converters. 2010.

- Gerber S, Hammoud A, Elbuluk M, Patterson R. Performance of High-frequency High-flux Magnetic Cores at Cryogenic Temperatures. 2002.

- Wyns P, Anderson R. Low-temperature operation of silicon dynamic random-access memories. IEEE Transactions on Electron Devices. 1989;36:1423-1428.

- Clark W, El-Kareh B, Pires R, Titcomb S, Anderson, R. Low-temperature CMOS-a brief preview. 41st Electronic Components and Technology Conference. 1991:544-550.

- Sheldon D, Burke G, Argueta A et al. Cryogenic Operation of Field Programmable Gate Arrays. NASA Report. 2011.

- Patterson R, Hammoud A, Panko S. “Evaluation of Fairchild's Gate Drive Optocoupler”, Type FOD3150, Under Wide Temperature Operation. 2010.

- Gurevich V. Electric Relays: Principles and Applications. 2005.

- Tugnawat Y, Kuhn W. 12th NASA Symposium on VLSI Design. 2005.

- Elbuluk M, Gerber S, Hammoud A, et al. Efficiency and Regulation of Commercial Low Power DC/DC Converter Modules at Low Temperatures. Energy Conversion Engineering Conference and Exhibit. 2000.

- Abebe H, Tyree V, Cockerham N. SPICE BSIM3 Model Parameters Extraction and Optimization for Low Temperature Application. NSTI-Nanotech.2009;3.

- Akturk A, Potbhare S, Booz J, et al. CoolSPICE: SPICE for Extreme Temperature Range Integrated Circuit Design and Modeling. SISPAD 2012.

- Chen Y, Mojaradi M, Kolawa E. Design for reliability approach for electronics under extreme temperature applications. NASA Jet Propulsion Laboratory Report. 2014.

- Mouthaan A, Salm C, Lunenborg M et al. Dealing with hot-carrier aging in nMOS and DMOS, models, simulations and characterizations. Microelectronics Reliability. 2000:40:909-917.

- Dunn B. The Resistance of Space-Quality Solder Joints to Thermal Fatigue. Circuit World. 1979;5:11-17.

- Dunn, B. “The Resistance of Space-Quality Solder Joints to Thermal Fatigue". Circuit World. 1979;6:16-27.

- Dunn B. Materials and Processes for Spacecraft and High Reliability Applications. MRS Bulletin. 2016.

- Girard G, Martiny M, Mercier S, et al. Interests Of Precise Material Characterization To Assess The Reliability Of Printed Circuit Boards By Combining Numerical And Experimental Approaches. ESA, 8th Electronic Materials and Processes for Space Workshop. 2017.

- Dunn B. 6th Electronic Materials and Processes for Space Workshop. SMT Magazine. 2015.

- Engelmaier W. Fatigue of leadless chipcarrier solder joins during power cycling. Solder Joint Reliability Workshop notes. Engelmaier Associates. 1995.

- Ho Y, Nam S, Lee D, et al. Cryogenic impact resistance of chopped fiber reinforced polyurethane foam. Composite Structures. 2015;132.

- Masterbond. Adhesives, Sealants & Coatings for the Aerospace Industry. 2014.

- Vandevelde B, Gonzalez M, Limaye P, et al. Leadfree solder joint reliability estimation by finite element modelling: advantages, challenges and limitations. IPC-/JEDEC 7th international conference on Leadfree electronic components and assemblies. 2004.

- High reliability PCB test. ESA 9th Electronic Materials and Processes for Space (EMPS) Workshop. 2018.