Original Article

, Volume: 21( 1) DOI: 10.37532/0974-7486.21.001Preparation and Piezoelectric Characterization of (K0.5Na0.5)NbO3 Ceramic

- *Correspondence:

- J. Venkatesh

Department of Physics, Tjohn Institute of Technology, Bangalore, India

Tel: 9742846635

E-mail: jvenkatesh@tjohngroup.com

Received: November 25, 2022, Manuscript No. TSMS-22-81264; Editor assigned: November 28, 2022, PreQC No. TSMS-22-81264 (PQ); Reviewed: December 12, 2022, QC No. TSMS-22-81264; Revised: January 25, 2023, Manuscript No. TSMS-22-81264 (R); Published: February 03, 2023, DOI: 10.37532/0974-7486.21.001

Citation: Venkatesh J. Preparation and Piezoelectric characterization of (K0.5Na0.5) NbO3 ceramic. Mater Sci Ind J. 2023;21(1):001.

Abstract

In this article the preparation, microstructure, dielectric and piezoelectric properties of lead free piezoelectric ceramic (K0.5Na0.5) Nbo3 are reported. We have followed the conventional processing route to achieve 93%-94% density with average grain size distribution of about 10 microns. A longitudinal piezoelectric coefficient (d33) of 94 pm/v ± 0.8 pm/v and radial coupling coefficient KP of 33% have been obtained on this compound. The measured free permittivity and loss tangents at 1 kHz are found to be 436 and 9%, respectively.

Keywords

Microstructure; Dielectric; Piezoelectric properties; Radial coupling coefficient; Compound

Introduction

Piezoelectric ceramics find applications in numerous electromechanical devices, such as ultrasonic transducers, resonators, sensors, ultrasonic motors, actuators and transformers [1]. In this respect lead based ferroelectrics are among most widely used materials because of their superior piezoelectric properties over other compounds of special interest are compounds of the solid solution PbZrO3(PZ)-PbTiO3(PT) where the well-known Morphtropic Phase Boundary (MPB) composition (around 52 mol% PZ at room temperature) have been found to show anomaly in dielectric and piezoelectric properties [2]. But toxicity and environmental concerns of lead oxide which is released during materials processing because of its high vapor pressure have triggered increasing research activities/demand for environmental friendly alternative materials [3]. Several types of materials such as tungsten bronze based compounds bi-layered compounds and alkaline niobates have been tried for this purpose [4-7]. Among these materials alkaline niobates have been found to exhibit superior properties over other lead free compounds. Especially the compound K0.5Na0.5NbO3 (KNN) is reported to show high longitudinal piezoelectric coefficient, high radial coupling coefficient and low coercive field which make this material attractive as an alternative to lead based compounds. Furthermore, its lowest density reported so far makes this material suitable for underwater transducer application as it offers low acoustic impedance mismatch. The non-toxic nature of this material also makes it an attractive choice for medical applications.

Structural investigations of KNN showed the presence of a morphtropic phase boundary separating two orthorhombic phases at room temperature [8]. Because of the highest number of polarization orientation (12 directions) for orthorhombic phase and morpho tropic nature, the compound exhibits optimum piezoelectric properties.

However, only a limited number of investigations have been carried out on this material. Difficulties in densification at ambient pressure have been reported and the compounds prepared by conventional sintering in air often exhibit low density and poor piezoelectric properties compared to samples prepared by hot pressing and spark plasma sintering methods [9]. Effects of dopants (rare earth and alkaline earth) with mixed valence at A sites have been studied with respect to microstructure and piezoelectric properties and it has been reported that grain growth in this type of materials is assisted by the creation of charged defects at A and O sites of the perovskite unit cell (ABO3) [10].

The present work focuses on the preparation of pure KNN using conventional solid state reaction and air sintering routes. The processing conditions were optimized in order to obtain high density materials which are subsequently characterized in terms of microstructure, dielectric and piezoelectric properties.

Materials and Methods

The samples were prepared by conventional solid state reaction method. Reagent grade starting materials Na2CO3, K2CO3 and Nb2O5 (Alpha Aesar, with purities>99.9%) have been taken in stoichiometric ratio, mixed in agate ball mill using zirconium stabilized alumina balls in 2-propanol medium. Particular care was taken regarding moisture sensitive nature of carbonates. The mixture was dried and calcined at 800°C for 4 hours. The calcined powders were again ball milled in 2 proponal for 24 hours. The slurry was dried, crushed and passed through a 100 micron mesh to break agglomerates formed during mixing. The powders were pressed at room temperature into pellets and sintered at 1120°C for 2 h. Silver palladium electrodes were screen printed on both surfaces of the discs and fired at 820°C. For measurement of piezoelectric properties the samples were polled in a silicone oil bath at 80°C under a field of 2.9 kV/mm for 20 minutes. These poling conditions revealed to be best suited for our samples.

The density of the sintered samples was measured using the Archimedes method. The phase structure and composition were examined using X-ray diffraction (Cu-alpha radiation operating at 45 kV and 30 mA; Model Siemens 805). The microstructure of the sintered pellets was characterized using an analytical scanning electron microscope (Model Phillips XL30 equipped with EDAX). The dielectric properties were determined at 1 kHz using an impedance analyzer. The d33 measurements on the poled samples were carried out using a laser vibrometer ((Polytec OFV 353 sensor head and OFV 3001 vibrometer controller) under sinusoidal driving AC voltage generated by a function generator (HP 3325A). The AC voltage (peak to peak) was varied from 5 V to 40 V and the oscillation frequency was kept at 1 kHz. The resonance measurements were conducted using the impedance analyzer above. The electromechanical coupling factor KP was calculated from the resonance and the antiresonance frequencies on a 0.6 mm thick circular sample with a diameter of 6 mm.

Results and Discussion

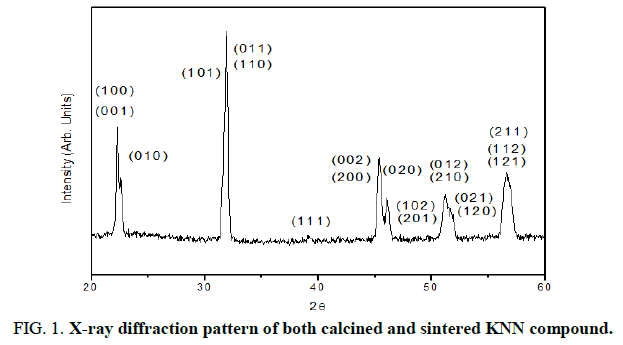

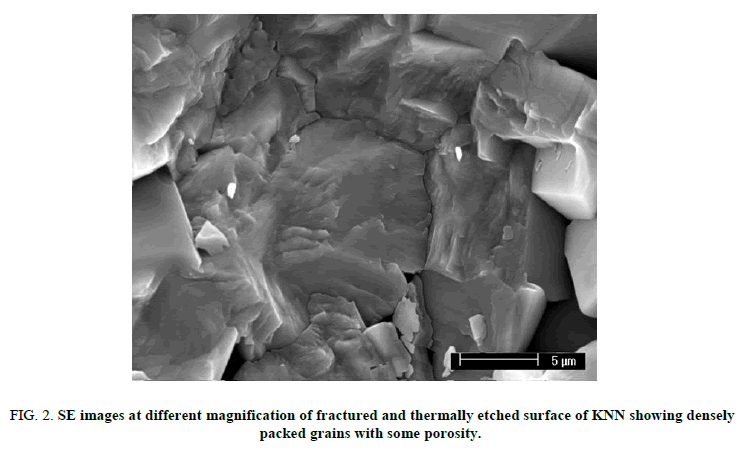

X-ray studies and microstructure

Figure 1 shows X-ray diffraction patterns of sintered samples which exhibit the expected orthorhombic structure. Figure 2 shows SEM micrographs of a fractured and thermally etched sample surface. The microstructure reveals densely packed cube shaped grains with few pores and an average grain size distribution of approximately 10 μm. The EDAX analysis did not reveal any departure from stoichiometry. The density values measured were found to be between 93% and 94% of the theoretical density of 4.51 g/cm3.

FIG 2: SE images at different magnification of fractured and thermally etched surface of KNN showing densely packed grains with some porosity.

Dielectric and piezoelectric properties

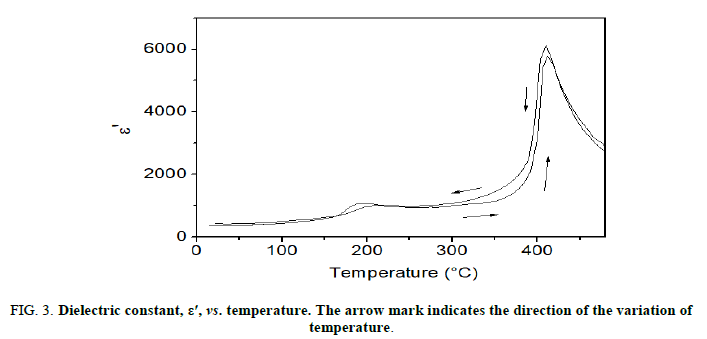

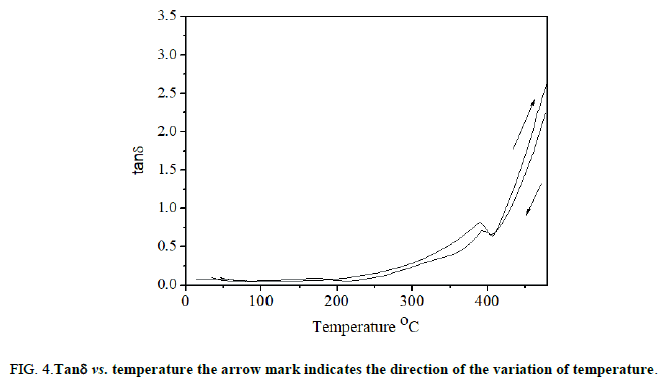

Figure 3 and Figure 4 shows the temperature dependence of the dielectric constant, ε' and loss tangent, tanδ, measured at 1 kHz both on heating and cooling. The high temperature peak around 410°C corresponds to the phase transition from tetragonal ferroelectric to cubic paraelectric phase (T-C). The low temperature peak around 190°C corresponds to the phase transition from the room temperature stable orthorhombic phase to tetragonal phase. A hysteresis in the temperature dependence of the dielectric properties on heating and cooling can also be noticed. The transition Temperatures (Tc) does not exactly match with the forward and reverse direction of temperature variation. This characteristic depicts a first order phase transition as observed on many ferroelectric compounds [11]. Below the orthorhombic phase transition the dielectric properties are very similar on heating and cooling. The range of the values of transition agree well with the (K,Na) NbO3 phase diagram. The room temperature values of ε' and tanδ are around 436 and 0.09 and lie in the range of values reported.

FIG 3: Dielectric constant, ε' vs. temperature. The arrow mark indicates the direction of the variation of temperature.

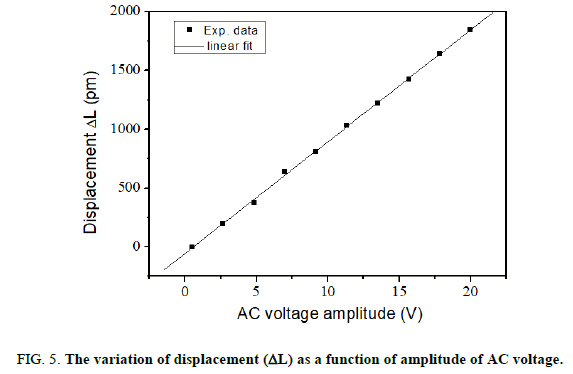

The value of the thickness mode piezoelectric coefficient d33 was obtained from the first harmonic surface displacement ΔL as follows:

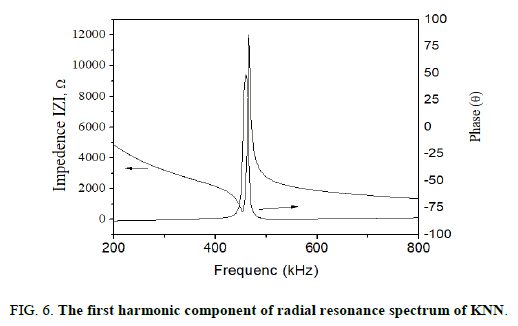

Where ΔV is the oscillation voltage amplitude. Figure 5 shows the variation of displacement with amplitude of oscillation voltage. The measured value of d33 is about 94 pm/V ± 0.8 pm/V which is higher than the value reported on the same composition prepared by conventional air sintering. This value is highest value reported for conventional air sintered undoped sample. Figure 6 shows the first harmonic contribution of radial resonance spectra of this compound. The planar coupling coefficient (KP) calculated from the resonance spectra is found to be 33%. The calculated value of k31 coupling coefficient is found to be 20%.

Conclusion

(K0.5Na0.5) NbO3 piezoelectric ceramics with 93% to 94% of theoretical density have been obtained by conventional solid state reaction. The microstructure reveals densely packed grains with an average size distribution of about 10 microns. Thermal hysteresis in dielectric properties reveals the presence of first order phase transition at Tc. The values obtained for the longitudinal piezoelectric coefficient (d33) of around 94 pm/V ± 0.8 pm/V and the radial coupling coefficient (KP) of approximately 33% compare well to those reported in literature.

References

- Haertling GH. Ferroelectric ceramics: History and technology. J Am Ceram Soc. 1999;82(4):797-818.

[Crossref]

- Jaffe B, Cook WR, Jaffe H. Piezoelectric ceramics. Academic Press, New York, 1971.

- Glass AM. Investigation of electrical properties of sr1-xbaxnb2o6 with special reference to pyroelectric detection. J Appl Phys. 1969; 40(12):4699-4713.

- Liu ST, Maciolek RB, Zook JD, et al. Electro-optic and ferroelectric effect in lanthanum doped strontium barium niobate single crystal. Ferroelectrics.1988;87(1):265-269.

- Fernandez JF, Caballero AC, Villegas M, et al. Relaxor behavior of PbxBi4 Ti3+ xO12+3x (x=2,3) aurivillius ceramics. Appl Phys Lett. 2002;81(25):4811-4813.

- Jaeger RE, Egerton L. Hot pressing of potassium sodium niobates. J Am Ceram Soc. 1962;45(5):209-213.

- Tennery VJ, Hang KW. Thermal and X-Ray diffraction studies of the NaNbO3-KNbO3 system. J Appl Phys. 1968; 39(10):4749-4753.

- Wang R, Xie R, Sekiya T et al. Fabrication and characterization of potassium-sodium niobate piezoelectric ceramics by spark plasma sintering method. Mat Res Bull. 2004;39(11):1709-1715.

- Shirane G, Newnham R, Pepinsky R. Dielectric properties and phase transitions of NaNbO3 and (Na,K) NbO3. Phys Rev. 1954;96(3):581-588.

- Yuhuan Xu. Ferroelectric materials and their applications. 1st edition, Elsevier Science Publishers, Bouvet Island. 1991.

- Kosec M, Kolar D. On activated sintering and electrical properties of NaKNbO3. Mat Res Bull. 1968;47:1151-1156.