Research

, Volume: 7( 2)Melon peel powder: Phytochemical Screening, Antioxidant Contents, Functional Properties Food Application

- *Correspondence:

- Benmeziane-Derradji Farida

Department of Agronomic Sciences, Chadli Bendjedid University,

El-Tarf, Algeria

Tel: 213775613108

E-mail: benmezianefarida@yahoo.fr

Received: July 21, 2022, Manuscript No. tsfsr-22-69783; Editor assigned: July 25, 2022, PreQC No. tsfsr-22-69783 (PQ); Reviewed: August 08, 2022, QC No. tsfsr-22-69783; Revised: October 06, 2022, Manuscript No. tsfsr-22-69783 (R); Published: October 14, 2022, DOI: 10.37532/ TSFSR.2022.07.97

Citation: Benmeziane-Derradji Farida, Aoun Sara, Achraf Cherifi, et al. Melon peel powder: Phytochemical Screening, Antioxidant contents, Functional Properties Food Application. J Food Sci Res. 2022;07 (02):97

Abstract

This study was developed for two reasons: (i) To characterize melon peel powder for its physicochemical and functional properties and content of bioactive molecules; (ii) to valorize the MRP as a by product by incorporating it into an industrially produced pasteurized dairy butter. Butter samples produced at the national dairy industry of Annaba Algeria were characterized for their physicochemical, microbiological and sensory properties. MRP showed both high water/oil absorption capacities (715.50% and 263.33%, respectively) and an interesting swelling capacity (22.50 mL/g). MRP extracts exhibited their richness in phytochemicals; anthocyanins, carotenoids, lycopene and chlorophylls have marked their presence in the MRP. The resulting powder from melon rind was incorporated at a rate of 1 g/kg in a dairy butter and results showed that MRP-enriched butter was more preferred by panelists after one month of storage (score of 6.7 on 9 point scale). The microbiological quality of butter was not improved upon the addition of the MRP. In conclusion, this detailed investigation carried out here for the first time represents a preliminary study to characterize and valorize the MRP and further investigations should be carried out in order to better valorize this by-product which could represents a strength for the country's economy.

Keywords

Cucumis melo L; Rinds; By products; Bioactive compounds; Functional properties; Food application

Introduction

The melon, scientifically named Cucumis melo L., is species derived from a plant in the Cucurbitaceae family. According to Mehra, melons have their origin in Africa and southwest Asia, but at the end of the Roman Empire, they begun to appear in Europe. World melon production is around 28.3 million tons. The first world producer is China with over 15 million tons (53% of world production). In Africa, the first melon producer is Egypt. Consumption of melon fruits during hot summer periods is a common practice that has been observed across the world due to its sweet taste and high water content which makes it diuretic fruit. As most of fruits, melon in low in calories, free from sodium and fat and nutrient rich and make a healthy contribution to diet. Nevertheless, while the pulp of melon is consumed or processed into other products such as juices, nectars, concentrates, jams and more, the non edible parts of the melon (seeds and peels) are discarded during the production process, attaining about 8 to 20 million tons of waste per year worldwide. This ‘waste material’ could pose ecological problems related to proliferation of insects and rodent as indicated by Falade. Therefore, from the environmental point of view, it is essential for these generated byproducts to be reused in the food or pharmaceutical industry for waste production reduction and environmental safeguard. Nowadays, consumers are more and more health conscious and aware of the link that can exist between their health and their well-being with their diet. Thus, due to the increase in chronic diseases, consumer demand for healthy and functional foods is booming; also, because of the environmental and economic impact of the waste, the reuse of byproducts is then necessary. Melon and its byproducts are an important source of bioactive compounds such as lycopene, vitamin C, β-carotene and polyphenols which have anti-inflammatory, anticancer and antioxidant properties [1-5]. The interest to melon by product has increased worldwide due to its nutritional value and the growing demand for natural and functional foods. However, few researches have been undertaken in terms of melon and seeds and even less concerning the peels. The studies carried out can be summed up in the characterization of some physicochemical and functional properties beside the antioxidant contents of mainly pulp and seeds. Parmar and Kar indicated that Indian Cucumis melo peel extract appears to be stimulatory to thyroid functions and inhibitory to tissue lipid peroxidation, thus protect against hypothyroidism. Therefore, new food formulations to integrate this functional ingredient are encouraged. The main objective of this work is the characterization of the physicochemical and functional properties and the determination of antioxidant molecule content in Melon Rind Powder (MRP) produced locally on the one hand and on the other hand, the test of incorporation of MRP into industrial dairy butter followed by the physicochemical, microbiological and sensory characterization of the developed product was performed [6-8].

Materials and Methods

Plant material:

The fruits of the melon (Cucumis melo L.), canary yellow, were bought from a local market in the locality of El-Kala a small town in the Wilaya of El-Tarf (latitude: 36.7672, Longitude: 8.31377 36°46′2″ North, 8°18 ′50″ East), Algeria. The melons were washed and cleaned of any adhering residue. After consuming the pulp, the melon rinds were collected and traditionally sun-dried on a clean line for a few days. The dried peels were ground in a domestic grinder (sonifer brand) to a fine powder. The MRP obtained, having a maximum particle size of 500 μm, was stored in airtight bags at 4°C until the time of analysis [9].

MRP characterization

Proximate physicochemical composition of MRP: The MRP was analyzed for its physicochemical characteristics. The powder was examined for pH (AFNOR), water content by drying in an oven at 10°C ± 2°C for 4 hours; titratable acidity (Verma and Joshi, 2000); color index which is expressed as the absorbance value at 420 nm of the MRP suspension; totaled soluble solids (TSS, °Brix) and refractive index measured with a benchtop refractometer; Electrical Conductivity (EC) with a conductivity meter and finally the absorbance at 280 nm was also determined [10].

Functional properties of MRP: In order to find a possible food application of melon peel powder, several so called functional properties have been determined according to our previously published methods of Benmeziane?Derradji. In addition, the method defined in the work of Martínez was used to evaluate the clarity of gel. The Hausner ratio and the Compressibility Index (CI) were measured according to the protocol of WHO.

Phytochemical screening: Tube tests are carried out on MRP in order to preliminary determines the nature of the various secondary metabolites it contains. This is a qualitative analysis based on coloring and/or precipitation reactions. The analysis is carried out on a dilute powder solution and on the powder itself. The classes of metabolites sought are: total tannins, anthocyanins, starch, mucilage, irridoids, alkaloids, terpenoids and reducing compounds [11-14].

Bioactive molecules determination

Preparation of extracts: The extracts were prepared by macerating 200 mg of melon peel powder in 10 mL of different solvents (80% methanol, 80% acetone, 80% butanol and distilled water). After 30 min. of stirring, the mixture was filtered and the extracts obtained were stored at -10°C until analysis.

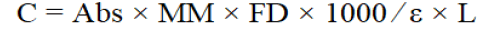

Antioxidant’s quantification in MRP: The total phenolic components were determined using the Folin-Ciocalteu method described by Nickavar. The reading was taken at 765 nm and the results were expressed as mg Gallic Acid Equivalent (GAE) /100 g of sample. The amount of total flavonoid was assessed according to the method of Kim. The reading was taken at 510 nm and the results were reported as mg Catechin Equivalent (CE)/100 g of sample. As for the condensed tannins (proanthocyanidins), they were estimated according to the previously described protocol by Vermerris. The reading was done at 530 nm and the results were reported as μg of Cyanidin Equivalent (CE)/100 g of sample using the formula:

Where Abs: Absorbance at 530 nm;

MM: Molar weight of cyanidin (287.24 g/mol);

DF: Dilution Factor;

L: Optical path; ε: Molar extinction coefficient of cyanidin 34700 L−1 mol−1 cm−1.

The determination of the total anthocyanins and total flavonols content was done using the procedure previously described by Ganjewala. The total anthocyanins contents were estimated from the absorbance read at 530 nm using a molar extinction coefficient (ε) of 29 000 L x mol-1 x cm-1 (recorded from a pure sample of delphinidin-3-rutinoside) and results were reported in mg of delphinidin-3-rutinosideeuivalent (D3RE)/100 g of sample; and that of the flavonols glycosides from the absorbance read at 360 nm (ε=20000 L x mol-1x cm-1, recorded from a pure sample of quercetin 3-glucoside) and results were reported in mg Quercetin 3-Glucoside Equivalent (Q3GE)/100 of sample [15-18].

The method reported by Sass-Kiss was followed to determine the total carotenoids and lycopene contents of MRP. Results were expressed as milligram β-Carotene Equivalent (βCE)/ 100 g of powder for carotenoids content and as mg of Lycopene Equivalent (LE)/100 g of MRP for the lycopene content [19,20].

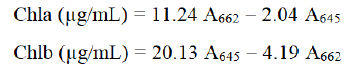

Chlorophyll contents were evaluated after extraction in 10 mL of acetone. The mixture was stirred for 30 min then centrifuged for 15 min at 3000 rpm. The reading of the supernatant absorbance was taken at two wavelengths: 662 nm and 645 nm in the UV/VIS spectrophotometer. The rates of the chlorophyll (chla) and chlorophyll b (chlb) were calculated using equations 1 and 2 (μg/mL) and were reported as mg/100 g of sample. Total chlorophyll content was calculated from the sum of chlorophyll a and chlorophyll b.

Total antioxidant activity: The phosphomolybdate test of Prieto et al. was followed to determine the total antioxidant activity of the different extracts.

Food applications using MRP: From our study, it was found that the MRP constitutes a valuable source of bioactive molecules and exhibited an attractive physicochemical, particularly pH and functional properties, notably water/oil absorption capacities and swelling capacity; therefore, the powder was used as functional ingredient to study its impact on dairy butter quality during the refrigeration storage. The dairy butter was prepared according to the standard diagram applied in the dairy industry “Edough” of the Annaba district (Algeria) which is based on the skimming of the milk and the churning of the pasteurized cream. Butter samples were divided into two portions and processed as follows:

Sample 1: Butter kept without addition of preservative (as it manufactured in the industry) and was considered to be as a control (BC).

Sample 2: Received the addition of 1 g of MRP per kg of butter and was considered to be as positive control (BM).

All samples were stored at 4°C during à period of 2 months. They were analyzed freshly (day 0), after one month (30 day) and at the end of the storage (day 60). The analysis was based on the physicochemical (fat, acidity, pH, moisture and density) and microbiological qualities (aerobic germs, fecal coliforms, Staphylococcus aureus, salmonella, yeasts and molds) and on the sensory properties.

Statistical analyzes: Results are presented as the mean of three tests ± standard deviation. All the data obtained were statistically treated by the one-way ANOVA test and the means of different treatments were considered to be significantly different at a p-value of 0.05 by Tukey's test. Statistical analysis was carried out using Minitab version 17 Software (Minitab Inc., State College, PA, United States) [21-25].

Physicochemical analysis

The physicochemical characteristics of MRP are collated in Table 1.

pH: The pH is a parameter determining the aptitude of the products to be preserved. It is one of the main obstacles that the microbial flora must surmount to ensure its proliferation. From the results, it is clear that MRP is an acidic powder with a pH of 5.76 which is due to the presence of organic acids in the powder. Result from the current study was close to the 5.8 reported by Miller, on melon peel powder. The pH of the melon peels of tibish variety decreased throughout fruit maturation from 5.29 to 4.65 [26-30].

Acidity: The acidity indicates the maturity of the fruit (this decreases during ripening) and the sugar/acidity ratio determines the sweet, balanced or sour character of the fruit. The MRP exhibited an acidity value of 19.23 ± 0.00%. The presence of certain organic acids (acetic, ascorbic, citric, fumaric, tartaric, galacturonic and malic) is responsible for the perceived acidity in plants, especially fruits. Thus, the relatively high acidity value observed in MPR probably due to a high content of organic acids allowing to bring out the flavor of the melon (which correlated with the sensory analysis) and it is suitable to preserve the organoleptic nature and bypass the fermentation processes. The acidity melon peel powder as found by was 19.4 meq/L.

Water content: The humidity test allows to know the water content of the melon rind (Cucumis melo). The results obtained showed that the melon rind has a moisture content of 14.13 ± 0.23%. This result was slightly lower than that reported by Mallek-Ayadi. On Tunisian Cucumis melo L. peels maazoun cultivar with a moisture content of 16.95%. This is probably due to varietal and/or geographic differences as well as the drying techniques applied [31-33].

TSS and refractive index: TSS is related to the sugars and acids amount in the analyzed product and it has a major impact on the flavor of the fruit. The TSS of MRP was of 3.9%, which means that it has low sugar as comparing to the 4.9% recorded by Miller in the peel of “Piel de Sapo” melon, which was the lowest value in comparison to the TSS of juice (8.8%), pulp (8.8%) and seeds (12.8%). Fundo have depicted a high content of TSS (5.67°Brix) in cantaloupe melon peel. As for the refractive index, reported for the first time in this study, this was of 1.336 (Table 1).

| Parameter | Melon peel powder |

|---|---|

| pH | 5.76 ± 0.02 |

| Acidity (%) | 19.23 ± 0.00 |

| Water content (%) | 14.13 ± 0.23 |

| °Brix (%) | 3.90 ± 0.10 |

| Refractive Index (RI) | 1.336 ± 0.00 |

| A420 | 1.262 ± 0.001 |

| A280 | 1.346 ± 0.007 |

| Conductivity µS/cm | 1356.3 ± 7.02 |

| Absorbance at 420 and 280. | |

Table 1. Physicochemical proximate analysis of MRP.

The recorded absorbances at 280 nm and 420 nm were 1.346 and 1.262, respectively. Comparatively, the value obtained at 280 nm was higher than that obtained at 420 nm. The absorbance at 280 nm can be explained by the presence of proteins and phenolic acid and their derivatives (flavones, flavonols, phenylpropenes and quinones), suggesting that the MRP is rich in phenolic acids and their derivatives as stated previously by Bunghez. Similarly, the absorbance at 420 nm can be explained by the formation of compounds resulting from the Maillard reaction that occurs during the reduction of sugar and amino acids during sun drying. Although this result possibly indicates a high abundance of early Maillard reaction products in MRP, Kang stated that a single molecule can absorb at both 420 and 280 nm and higher absorbances are usually observed at 280 nm.

The Electrical Conductivity (EC): The ability of the foods to conduct electric current is called electrical conductivity also called specific conductance. The EC is a key parameter for foods quality evaluation, process conception and improving processing technology. From Table 1, it appears that the EC was 1356.3 μS/cm, which considered as slightly low. There is now data regarding the EC of the MRP. The EC of Fuerte avocado fruits during ripening at 20°C were between 0.63 and 3.89 mS/cm.

Functional properties of MRP

The functional properties are mainly attributed to the chemical structure of polysaccharides and proteins of the peels, which largely affected by grinding, drying, heating, extrusion cooking etc. as stated by Dias. Thus, to have an insight on an eventual use as food ingredient of the MRP available in local market of El-Kala, the canary yellow melon was collected and the peels were recovered. The MRP obtained was analyzed for various functional properties which are summarized in Table 2. It must be noted that most of the functional properties are reported for the first time in the current study.

Solubility: To characterize the behavior of powder in aqueous solution, solubility is considered as the most reliable parameter. The MRP showed a solubility value of 22.65%, which was lower than the 83% observed for date powder prepared by oven dried and spray dried and lower than the 51.44 % reported by Chia and Chong (2015) on drum dried dragon fruit (Hylocereus polyrhizus) peel powder, but close to those reported by cangussu on mature and semi mature umbu (Spondias tuberosa A) peels flour with values of 20.42 and 14.34 g/100 g, respectively, depending upon carrier agents, conditions of preparations, particle diameter and type of raw material. Cangussu announced that low solubility in water is not desirable as it restricts the application in some food products, such as jams.

Hygroscopicity: A hygroscopicity of 2.06% was recorded in the MRP. Manickavasagan reported that the spray dried date powder produced at various conditions had hygroscopicity ranging 0.03-0.08 g/g of powder. The hygroscopicity can vary from powder to powder depending upon the composition of powder. The nature and the rate at which the powders produced hold molecules of water from the surrounding air can explain the differences in hygroscopic values. Adetoro evidenced that the moisture absorbs capacity is related to the number of hydrophilic groups present in the structure of each powder. They found in pomegranate juice powder hygroscopicity values between 4.7% and 12.6% according to the treatment.

Bulk density: The bulk density is the measure of the heaviness of the powder; it depends on particle size and initial moisture content. The MRP had a bulk density of 0.40 g/mL which was lower than the 0.29 g/mL recorded in avocado and yellow passion fruit peels, but closer to the 0.37 and 0.39 g/mL noted in the orange and pineapple peels. It is known that the lower the bulk density, the more packaging space is required. The MRP had a bulk density which was slightly high so it can be packed in a constant volume. The high bulk density of flour suggests their suitability for use in food preparations. On contrast, low bulk density would be an advantage in the formulation of complementary foods as well as in the preparation of infant and weaning foods (Table 2).

| Functional properties | Melon rind powder |

|---|---|

| Solubility (%) | 22.65 ± 0.97 |

| Hygroscopicity 7 (%) | 2.06 ± 0.71 |

| Bulk density (g/mL) | 0.40 ± 0.00 |

| Water absorption capacity (%) | 715.5 ± 0.71 |

| Oil absorption capacity (%) | 263.33 ± 3.06 |

| Hydrophilic / Lipophilic ratio (%) | 2.71 ± 0.003 |

| Whole milk absorption capacity (%) | 346.67 ± 22.12 |

| Skim milk absorption capacity (%) | 450.00 ± 20.00 |

| Foaming activity (%) | 6.66 ± 0.00 |

| Foaming stability (%) | 93.75 ± 0.00 |

| Emulsifying activity (%) | 23.92 ± 0.99 |

| Emulsion stability (%) | 89.25 ± 0.65 |

| Swelling capacity (mL/g) | 22.50 ± 2.50 |

| Least gelation concentration (%) | 8 |

| Clarity of powder (%) | 3.67 ± 0.15 |

| Hausner ratio | 1.10 ± 0.02 |

| Compressibility index (%) | 8.89 ± 1.93 |

| Each value in the table is the mean ± standard deviation (n = 3). | |

Table 2.Techno functional properties of melon rind melon.

Water and Oil Absorption Capacities (WAC, OAC) and Hydrophyly/Lipophyly Ratio (HLR): An elevated hydrophilic tendency (WAC) of 715.5% was observed in MRP, this result testifies to the great capacity of melon powder to absorb water; this characteristic is of great importance and makes it an interesting techno functional food ingredient. This result was close to the 7.7 g H2O/g found by Al-Sayed and Ahmed on Egyptian sharlyn melon (Cucumis melo) peels, but higher than that recorded by Koubala on the peels of Cucumis melo (Tibish variety) from Cameroon, at different stages of maturity where the WACs varied between 4.43 and 6.09 mL/g and the 5.36 g water/g peel reported by Mallek-Ayadi on Tunisian maazoun melon peels and lower that the 9.63 mL/g reported by Dias on yellow passion fruit peel. As stated by Emelike, powders with elevated WAC can be used as a thickening agent in foods pointing out that MRP will serve this purpose. Furthermore, a high water absorption rate is very important for many products because water interferes with texture and juiciness and also prevents water loss during cooking.

Compared to the WAC, the OAC was lower since the recorded result was 263.33%. This value is almost three times less than the WAC. It is essential to assert that, this result can be considered beneficial and positive since the low OAC does not cause a caloric increase in the product after exposure to oils. Comparable values were reported by Mallek-Ayadi (2.23 g oil/g peel); Al-Sayed and Ahmed (2.24 g oil/g peel) and Weng (2.44 g/g and 2.38 g/g on yellow and purple passion fruit peel flour, respectively); however, our finding was higher than that reported on pineapple peels (1.90 mL/g) and lower than the 3.10 mL/g observed on avocado peels. Nevertheless, melon peels can retain up to 2.5 times their mass in oil, which is interesting from the point of view of improving the ability to retain fat in products that are rich in it, such as butter and meat products which are normally lost during cooking. This property can thus be exploited for the rising of flavor retention of the products proving an improved taste to foods.

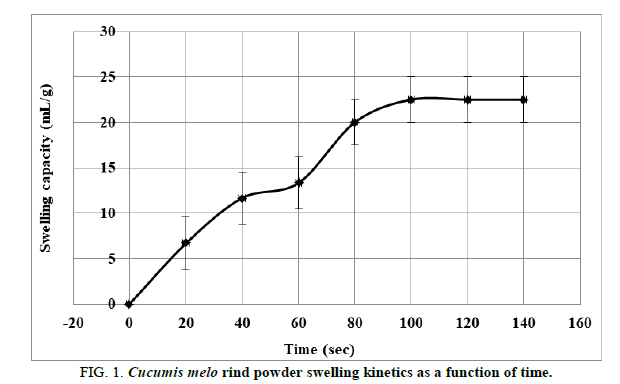

The ratio HLR was far from higher than 1 (2.71) which means that the MRP has more affinity to water than to oil, as consequence, the MRP could be more favorably used in the products formulation necessitating a high WAC. The affinity towards water is linked to powder composition suggesting the presence of more hydrophilic chains that resulted in higher water absorption capacities. Lower HLR ratios of 1.06 and 1.86 have been previously reported by Benmeziane-Derradji on unroasted and roasted lentil flours, respectively (Figure 1).

Whole milk absorption capacity and skim milk absorption capacity: Both of these features are first reported in melon peel powder. The whole milk absorption capacity and skim milk absorption capacity were 346.67% and 450.00%, respectively, as results, the melon powder can be used effectively in the design of dairy products such as fermented milks (yogurt), cheese, creams, dairy desserts and instant baby food or in breakfast products, such as cereals and cornflakes.

Foaming Activity (FA) and Foaming Stability (FS): The MRP exhibited a slightly low FA of 6.66% but the foam formed was highly stable with a percentage of 93.75%. Similar tendencies were reported by Noor on mango peel flour with a respective FA and FS of 2.59% and 96.84%. Deb stated that the fact that proteins can easily diffuse in the air-water interface and form a cohesive and elastic film by partial unfolding, they represent good foaming agents. This explains the low foaming capacities due to the fact that MRP is not a rich protein source. On the other hand, the high FS obtained can be explained, according to the same authors, by protein molecules forming persistent intermolecular polymers surrounding the air bubbles, since intermolecular cohesion and elasticity are the two principal factors necessary for good foam stability. Higher FCs were observed by Deb on different protein fractions (albumin, globulin, prolamin and glutelin) of banana peels with respective values of 14.33%, 17.10%, 15.23% and 19.13% and by Dias on peels of avocado, yellow passion fruit and orange with rates of 8.47%, 22.67%, 10.00%, 16.67%, respectively with a respective low FS of 11.84%, 8.84%, 18.28% and 12.26%.

Emulsifying Activity (EA) and Emulsion Stability (ES): The capacity of a molecule to behave as an element promoting the solubilization or dispersion of two immiscible phases defines the emulsifying activity, while the ability to hold the emulsion stable describes the emulsifying stability. An EA of 23.92% and ES of 89.25% were obtained on the MRP. The different protein fractions isolated from the peel of bananas constituted good emulsifying agents because respective percentages of emulsifying capacity of 59.27%, 49.96%, 30.77% and 59.16% were noted on albumin, globulin, prolamin and glutelin. Alfredo claimed that EA also reflects the ability to adsorb bile acids and increases fecal excretion, thereby limiting the absorption of these acids in the small intestine and consequently reducing blood cholesterol levels which constitute a health benefit. It turns out that the addition of MRP; even with low EA, in food matrices is interesting in the formulation of functional food.

Least Gelation Concentration (LGC): The fiber, polysaccharide and pectin contents have a significant effect on the gelation properties. It was observed that at 8%, the MRP formed a stable gel which did not flow after inverting the tube, although a gel was formed at the first 2% concentration, but was not completely stable. Different LCGs of 10%, 9%, 8% and 3% were recorded in peel from four fruit varieties namely avocat, pineapple, yellow passion fruit and orange.

Swelling Capacity (SC): Swell ability reflects the ability of a powder to swell in an aqueous medium. The MRP had an SC of 22.50 mL/g with a significant WAC (715.15%). These two properties when high, testify according to Dias, Chia and Chong, the ability of the powder to increase average viscosity of food, modify the texture of formulated products, act as an emulsifying, form gels, induce a satiety effect and a large fecal bolus, thereby reducing the absorption of glucose, fats and cholesterol. Conversely, Weng indicated that a higher SC they recorded on purple and yellow passion fruit peel flour (9.24 cm3/g and 8.60 cm3/g) than that of wheat flour, implies that the excessive incorporation of these powders in the formulation of biscuits will adversely affect the moisture content during the baking process. Lower SCs were, previously, obtained on powdered peels of avocado, pineapple, yellow passion fruit and orange with rates of 4.36, 7.57, 16.94 and 8.98 mL/g, respectively, on composite powders peel fruits (passion fruit peel, pineapple peel and orange peel which ranged from 5.58 ml/g to 8.44 ml/g and on dragon fruit peel with 6.233 mL/g.

Clarity of gel: Dough clarity is a much desired feature of flour used as a thickener in food in the food industries since it directly influences the brightness and opacity of the food. From Table 1, it can be seen that the MRP had exhibited gel clarity of 3.67%. This low clarity of the gel formed by MRP can be explained by the presence of polysaccharide in its composition, in particular pectin.

Flow characteristics (Hausner Ratio (HR) and Compressibility Index (CI)): The measure of the powder free flow characteristic corresponds to its flow ability. Caliskan and Diri have underlined that correct flow of the powder is for a great importance for, not only manufacturers but also for end users to handle the powder. The MRP flow ability characteristics were assessed using the Compressibility index and Hausner ratio. In this study, the HR and CI of the MRP were, respectively 1.10 and 8.89%; the powder is considered to be with very good flow ability (CI?15) and with a low cohesiveness (HR?1.2) according to the classification given by the Caliskan and Diri. Sidlagatta asserted that the rate of powder moisture notably impacts flow ability, adhesion and caking properties. The authors added that large interactions between particles lead to larger CI values. Tze have evidenced in their study on pitaya fruit powders which had poor flow ability, that powder with smaller particle size has poor flowing properties. As the MRP presented very good flow ability, it can be concluded that the powder has a raised particle size. Freeze dried sumac extract powder with the high maltodextrin concentration (30%) showed good flow ability (CI of 28.21%) and low cohesiveness (HR of 1.391). The respective CI and HR of sweet orange powder spray dried from control juice were in the range of 12.2 to 22.8 and 1.14 to 1.29 and for concentrated juice powder were in the range of 15.4-24.9 and 1.18 to 1.33, respectively.

Phytochemical screening: The first method performed to provide information’s as regard to the presence of phytochemical compounds in the analyzed powder is the phytochemical screening or preliminary test. Results from Table 3 revealed the presence of metabolites in the MRP namely tannins, glucosides, mucilage, alkaloids, terpenoids and reducing compounds. The natural occurrence of these compounds confers to MRP a wide spectrum of biological activities such as antidepressant, antihypertensive, anti-inflammatory and others.

| Melon rind powder | |

|---|---|

| Tannins | + |

| Anthocyanins | - |

| Starch | - |

| Glucosides | + |

| Mucilage | + |

| Iridoids | - |

| Alkaloids | + |

| Terpenoids | + |

| Reducing compounds | + |

| (+) presence; (-) absence | |

Table 3. Phytochemical screening of powder of melon rind.

Antioxidant contents

Total Phenolic Content (TPC), Total Flavonoid Content (TFC) and Condensed Tannins Content (CTC): The results for the assessment of TPC, TFC and CTC are shown in Table 4. In this study, total phenols content in MRP were influenced by the type of solvent although the solvents used for the extraction of phenolic compounds from melon rinds, which were water, aqueous methanol, aqueous acetone and aqueous butanol all at 80% (80:20 v/v), all of them were able to extract phenolic compounds with different extracting powers. The methanolic extract stood out with the highest TPC concentration of 1271.39 mgGAE/100 g of TPC against (963.06 963.06 and 963.06) mg, GAE/100 g in hydroacetonic, hydrobutanolic and aqueous extract, respectively. The results of the present study were consistent with those obtained by Rolim who noticed that all tested solvents (water, aqueous methanol (70:30 v/v) and aqueous ethanol (70:30 v/v) were effective in extracting the bioactive compounds, highlighting the hydromethanolic extract, which showed high solubility for the phenols producing 703.1 mg GAE/100 g in melon peel flour against only 203.1 and 110.7 mg GAE/100 g in hydroethanolic and aqueous melon peel extracts. Fundo noted TPC content in the methanolic extract (100%) of cantaloupe melon rind (Cucumis melon L. var. Reticulatus) of 141.89 μg/g, lower than our findings. As for TFC, melon peels have been found to be a rich source of these compounds and the high content was recorded in the butanolic extract, without however any differences (p?0.05) being noted between the various solvents tested. In fact, the contents were respectively (112.22, 121.11, 124.44 and 112.22) mg EC/100 g in the metahnolic, acetonic, butanolic and aqueous extracts. The study of Mallek-Ayadi who investigated the phytochemical composition and functional properties of Tunisian melon peel (maazoun cultivar) found that it is a rich source of antioxidants such as polyphenols and flavonoids (332 and 95.46 mg/100 g extract, respectively). Flavonoid contents lower than those recorded in the current study were noted by Rolim in hydromethanolic, hydroethanolic and aqueous extracts with respective levels of 125, 104 and 262 (μg EC/100 g).

| Melon rind extracts | ||||

|---|---|---|---|---|

| Hydromethanolic | Hydroacetonic | Hydrobutanolic | Aqueous | |

| (80:20 v/v) | (80:20 v/v) | (80:20 v/v) | ||

| TPC (mg GAE/100 g) | 1271.39 ± 80.27a | 963.06 ±15.43b | 694.78 ± 14.41c | 698.18 ± 32.68c |

| TFC (mg CE/100 g) | 112.22 ± 86.30 a | 121.11 ± 3.47a | 124.44 ± 12.62a | 112.22 ± 2.55a |

| CTC (µg CE/100 g) | 427.69 ± 19.12b | 452.52 ± 81.25a,b | 515.98 ± 53.22a,b | 562.89 ± 24.83a |

| TPC: Total Phenols Compounds; TFC: Total Flavonoids Content; CTC: Condensed Tannins Content. | ||||

Table 4. Quantification of total phenolic compounds, total flavonoids and tannins in MRP extracts.

The tannin contents of the different extracts of the MRP are shown in Table 4. In comparison with TPCs and TFCs, the CTC contents were much lower in all the solvents tested, which means that the melon peels analyzed in this study do not constitute an important source of these molecules. In fact, the respective contents recorded in μg/100 g were 427.69, 452.52, 515.98 and 562.89 in the metahnolic, acetone, butanolic and aqueous extracts. It can be clearly seen that the water has extracted more tannins compared to the other solvents. This significant difference (p?0.05) noted between the extraction powers underlines, once again, the implication of the polarity of the compounds to be extracted compared to that of the solvent used giving rise to multiple protocols for the extraction of bioactive molecules. Contrary to what is observed in the present study, Rolim could not determine the condensed tannins in the ethanolic and aqueous extracts of the melon peel, although they noted a content of 309 μg EC/100 g in the methanolic extract, a lower value than our findings.

Pigment content of MRP: The pigment contents (anthocyanins, flavonols, carotenoids, lycopene, chlorophyll a, chlorophyll b and total chlorophyll) of MRP are shown in the Table 5. The anthocyanins were detected at a level of 14.81 ± 2.36 mg ED/100 g. Lower levels were found in kiwi and pineapple peels of 0.116 and 0.105 mg/g, respectively, while respective higher levels of 0.24, 0.83 and 0.811 mg/g were noted in banana, apple and orange peels. Many previous studies in vivo and in vitro have been demonstrated the health benefits effects of anthocyanins (anticancer activity, anti-inflammatory activity, neuroprotective activity, anti-obesity and antidiabetic activity, cardiovascular disease protection, hypouricemic effects). Furthermore, the results indicated that melon rind is a rich source of flavonols which displayed a content of 149.85 ± 13.46 mg/100 g.

| Melon rind powder | |

|---|---|

| Anthocyanins (mgED/100 g) | 14.81 ± 2.36 |

| Flavonols (mgEQ/100 g) | 149.85 ± 13.46 |

| Carotenoids (mgβCE/100 g) | 18.48 ± 1.98 |

| Lycopene (LE/100 g) | 3.57 ± 1.18 |

| Chlorophyll a (mg/100 g) | 0.35 ± 0.01 |

| Chlorophyll b (mg/100 g) | 0.62 ± 0.03 |

| Total chlorophyll (mg/100 g) | 0.97 ± 0.03 |

Table 5. Pigment content of MRP.

Results and Discussion

The results obtained showed that the respective levels of carotenoids and lycopene recorded in the powder of the melon rind were 18.48 mg/100 g and 3.57 mg/100 g while the levels of chlorophyll a, b and total chlorophyll were 0.35, 0.62 and 0.97 mg/100 g, respectively. However, the level of carotenoids noted in the present study was much lower than that recorded by Fundo, in the rind of cantaloupe melon (Cucumis melon L. var. Reticulatus) who noted a value of 23.46 mg/g, but a little closer to the content noted by Rolim, which was 96 μg/g. Carotenoids were evaluated in all parts of “Piel de Sapo” melon but were not detected in any fruit part. The lycopene, a pharmacologically active carotenoid and a major bioactive constituent in many plants, was reported for the first time in the RMP. It was found that this food matrix is a good source of this compound which is of a great interest, since lycopene has several demonstrated biological activities and pharmacological benefits such as anticancer, antioxidant, cardioprotective and antihypertensive effects. The levels of chlorophyll a, b and total chlorophyll in MRP from the current study were close to those recorded by Fundo, as they recorded respective rates of 45.82, 32.95 and 78.77 (μg/g) and those of Miller who indicated that “Piel de Sapo” melon peel from Portugal presented the highest content of total chlorophylls of 87.85 ± 10.47 μg/g, distributed into 57.50 μg/g of chlorophyll a and 30.36 μg/g of chlorophyll b comparing to juice and seeds of the same fruit. The significant levels of chlorophyll pigments in rind matrices, with already demonstrated biological properties such as antioxidant activities and prevention of cancer and other degenerative diseases, underlines the importance of valorization of melon waste. The differences between the results can be explained by varietal differences and / or the sensitivity of carotenoids to heat, light and also to drying and storage conditions.

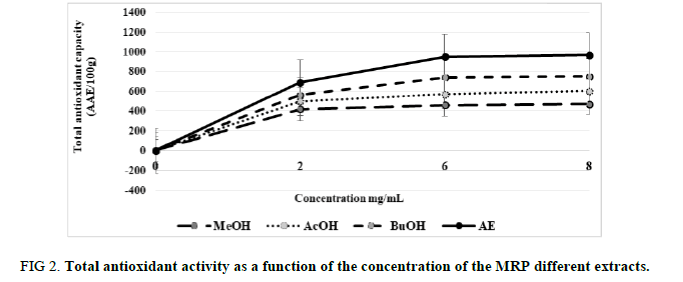

Antioxidant activity: The ammonium phosphomolybdate test is a quantitative method for determining antioxidant capacity. It is based on the reduction of Mo+6 to Mo+5 and the formation of a green colored phosphate/Mo+5 complexes in an acid medium. The results of the total antioxidant activity are expressed in milligram equivalent ascorbic acid per hundred grams of dry matter (mg ET/100 g DM) at different concentrations. The results indicated that the total antioxidant activity raised as the extract concentration increased. The statistical study shown that there is a significant difference (p<0.05) between the antioxidant capacity of the different extracts MRP (Figure 2 and Table 6).

| Extract | TAA | EC0.5 (mg/mL) |

|---|---|---|

| Methanolic | 458.93 ± 9.20a | 15.53 ± 0.33c |

| Acetonic | 127.05 ± 3.91c | 28.48 ± 0.81a |

| Butanoic | 162.80 ± 6.28b | 22.69 ± 1.04b |

| Aqueous | 172.50 ± 16.31b | 19.56 ± 2.67b |

| TAA: Total Antioxidant Activity expressed as mg EAA/100 g; Different letters in the same column indicate a significant difference (p<0.05). The results are ranked in descending order (a ? b ? c). | ||

Table 6. Total antioxidant activity and the EC0.5 of the different extracts of MRP (Cucumis melo L.).

MeOH: Methanolic extract; AcOH: Acetonic extract; BuOH: Butanoic extract; Aqueous extract.

The results in our study showed that the methanolic extract gave the lowest CR0.5 (15.53 mg/mL) i.e. the most important activity (458.93 mg EAA/100 g DM) compared to the other extracts. This result supposes that the MRP methanolic extract could contain more primary antioxidants molecules capable to react aggressively with free radicals thus stopping the radical chain reaction. In the same lines, Ganji evidenced in their earlier study that the antioxidant activity of methanolic extracts from peel powders of 12 commercial melons (Cucumis melo) had an interesting antioxidant activity (in mg ascorbic acid equivalents/mL extract) which ranged from 0.13 (organic Tuscan) to 0.26 (organic Galia). The results of the present study were in agreeance with literature data when compared to the results published by Rolim, where the methanolic extract, in addition to ethanolic melon peel extract showed respective total antioxidant activities of 74.5 ± 2.76 and 88.7 ± 2.99 (mg AAE/ g) significantly high compared to the aqueous extract which has showed an activity of 40.3±2.04 mg AAE/g). The observed differences from the results found in the current study may be due to varietal differences, extraction techniques and/or dosage, as well as the extracts bioactive substance content: noting that the antioxidant power is relate to the amount of phenolic compounds. The antioxidant power of the Muskmelon (Cucumis melo L.) peels (2.27 ± 1.22 mg AAE/g) and the EC0.5 (6.65 mg/mL) was higher than that recorded results in our study as reported by Vella. The results obtained in the present study are interesting, making MRPs a suitable alternative to replace synthetic antioxidants, which are not only safe, but also protect foodstuffs and improve consumer health.

Food application

In this study, the incorporation of MRP into dairy butter is reported for the first time. Butter samples were analyzed for their physiochemical, microbiological and sensory properties.

Physicochemical quality: It was observed that after one month of storage, the fat content was lower in the melon butter compared to the control butter; this situation can be explained by the oil absorption capacity of MRP. The addition of MRP led to a decrease in the pH in the butter, which varied between 4.36 and 5.22, whereas, in the control butter, the pH was between 4.77 and 5.53. The pH of both samples tended to decrease with increasing storage time. An opposite situation was noted for the acidity where it tended to increase from 6 to 10% with no difference for the two samples. This case can be explained by post acidification occurring during storage due to lactic acid bacteria naturally present in the product. The humidity rate recorded (12.73%-14.28%) was within the standards since the contents were less than 18%. As for the density, this was stable (0.93) during all storage period for both butter samples (Table 7).

| Fat (%) | Acidity(%) | pH | Moisture (%) | Density | ||

|---|---|---|---|---|---|---|

| Day a0 | Control butter | 85.71 | 6 | 5.53 | 14.28 | 0.93 |

| Melon butter | 86.94 | 6 | 5.22 | 13.06 | 0.93 | |

| Day 30 | Control butter | 87.09 | 8 | 5.06 | 12.9 | 0.93 |

| Melon butter | 86.98 | 8 | 4.76 | 13.01 | 0.93 | |

| Day 60 | Control butter | 87.26 | 10 | 4.77 | 12.73 | 0.93 |

| Melon butter | 87.11 | 10 | 4.36 | 12.88 | 0.93 |

Table 7. Physicochemical characteristic of butter samples.

Microbiological quality: The microbiological analyzes showed that the freshly made butters and the butters after a month of storage showed their full compliance with the Algerian standards, being free from yeasts and molds and pathogenic germs in terms of Staphylococcus aureus and Salmonella. Fecal coliforms were also absent, testifying to the sanitary quality and compliance with good hygiene practices in the manufacture of butter, while the total mesophilic aerobic flora marked its presence, but without exceeding the standards described by JORA (102-103 germs/g product). However, after two months (60 days) an increase in the microbial load of the total germs was observed in such a way that the results exceeded the norm, making the butter unfit for consumption. This can be due to the contaminations over storage; so, to avoid contamination, special attention must be paid to storage conditions.

Based on these results, it can be concluded that melon powder had no significant impact on the microbiological quality of the butter and thus on shelf-life extension (Table 8).

| Control butter | Melon butter | Standard | |

|---|---|---|---|

| Day 0 | |||

| Aerobic germs at 30°c | 2 × 102 | 9 × 102 | 102 -103 cfu/g |

| Total coliforms | 00 | 00 | 10 cfu/g |

| Staphylococcus aureus | ABS | ABS | 10 cfu/g |

| Salmonella | ABS | ABS | Absence in 25 g |

| Yeasts | ABS | ABS | ABS |

| Molds | ABS | ABS | ABS |

| Day 30 (1 month) | |||

| Aerobic germs at 30°c | 3×102 | 9×102 | 102 -103 cfu/g |

| Total coliforms | 0 | 00 | 10 cfu/g |

| Staphylococcus aureus | ABS | ABS | 10 cfu/g |

| Salmonella | ABS | ABS | Absence in 25 g |

| Yeasts | ABS | ABS | ABS |

| Molds | ABS | ABS | ABS |

| Day 60 (2 months) | |||

| Aerobic germs at 30°c | 7 × 102 | 4 × 103 | 102 -103 cfu/g |

| Total coliforms | 0 | 0 | 10 cfu/g |

| Staphylococcus aureus | ABS | ABS | 10 cfu/g |

| Salmonella | ABS | ABS | Absence in 25 g |

| Yeasts | ABS | ABS | ABS |

| Molds | ABS | ABS | ABS |

| ABS: Absence. | |||

Table 8. Microbiological quality of butter during cold storage (two months).

Sensory analysis: The evaluation of the organoleptic quality of a new food product is considered inevitable step before marketing. Panelist data scores (mean ± SD) for butter sensory assessment are exposed in Table 9. As it can be seen, the storage had impacted some butter organoleptic properties according to the panelist’s scores. Storage was found to have a greater impact on the panelist's ratings of the MRP enriched butter than the control butter. Except taste intensity which was rated low to medium (2.3) at D0 and very low to low (1.8) after one month of storage and spread ability rated at D0 (1) as very low and low to medium (2.2) à J30; for other sensory characteristics, there were no significant differences (p?0.05) between the freshly produced control butter and after one month of storage. Significant differences (p?0.05) were observed for the MRP-enriched butters in terms of their color intensity and texture, the assigned scores decreased from 2.4 and 4.1 (D0) to 1.7 and 3.5 (D30), respectively; while the scores recorded for spread ability increased from 1 (D0) to 2.1 (D30).

| Storage period | J0 | Month 1 | ||

|---|---|---|---|---|

| Butter samples/Sensory attributes | Control butter | Melon butter | Control butter | Melon butter |

| Color intensity | 2.1 ± 0.57a,A | 2.4 ± 0.52a,A | 1.6 ± 0.52a,A | 1.7 ± 0.48b,a |

| Smell intensity | 1.9 ± 0.32a,A | 2.6 ± 1.07a,A | 2 ± 0.67a,A | 2.1 ± 0.57a,A |

| Taste intensity | 2.3 ± 0.48a,A | 2.7 ± 0.82a,A | 1.8 ± 0.42b,b | 2.4 ± 0.52a,A |

| Aftertaste | 1.1 ± 0.32 a,A | 1.1 ± 0.32a,A | 1.1 ± 0.67a,A | 1.1 ± 0.32a,A |

| Consistency | 2 ± 0.47 a,A | 1.8 ± 0.63a,A | 2.2 ± 0.42a,A | 2.2 ± 0.42a,A |

| Texture | 3.9 ± 0.32a,A | 4.1 ± 0.57a,A | 3.4 ± 0.70a,A | 3.5 ± 0.53b,a |

| Spreadability | 1 ± 0.00b,a | 1 ± 0.00b,a | 2.2 ± 0.42a,A | 2.1 ± 0.57a,A |

| Overall acceptability | 5.8 ± 1.55a,A | 6.7 ± 1.49a,A | 5.60 ± 1.07a,b | 6.7 ± 1.06a,A |

| Different letters in the same line indicate a significant differences (p<0.05); a and b letters: Show differences between the same butter according to the day of storage; A and B letters: Show differences between the two butter samples during the same day of analysis; Results are ranked in descending order; a>b/A>B. | ||||

Table 9. Sensory assessment of MRP fortified butter as compared to control butter.

With the exception of taste intensity and overall preference, where MRP enriched butter scored significantly (p?0.05) higher for these hedonic sensory descriptors with respective scores of 2.4 and 6.7 compared to the control butter, no significant differences (p?0.05) were detected throughout the storage period between the two butter samples. It can be concluded that the MRP had an impact on the taster’s overall acceptability. In general, these few differences noted between butters during storage can be explained by the amount of MRP incorporated (1 g/kg). Therefore, further more in depth studies can be performed to check the effects of adding different MRP concentrations on butter quality.

Conclusion

The results of this study provided insights, particularly in terms of functional properties for possible new potential uses of melon residues. Based on the results obtained, the analyzed peels showed interesting characteristics in terms of functional properties where the MRP had excellent water/oil absorption capacities and swelling capacity which have potential to use as food hydrocolloid. In addition to having good technological properties, melon peel extracts as a byproduct, contain variety of healthy bioactive compounds particularly, polyphenols, carotenoids, lycopene and could contribute to the intake of natural antioxidants that can turn such wastes into functional ingredients. So, an attempt to valorize MRP in a food product was carried out in the present study and results have shown that addition of MRP to an industrial dairy butter did not compromise the manufacturing process and the product obtained is considered functional and was appreciated by tasters. Finally, it can be concluded that the very hopeful results obtained are fundamental for the application in the food industry in terms of the possibility of use of melon peel wastes as a promising natural additive in numerous food applications in order to develop novel functional foods. Therefore, the byproduct valorization constitutes a challenge for a sustainable development and strategies to improve ways of melon rind reuse should be developed and put in place by the authorities concerned.

Acknowledgement

The authors thank the Algerian Ministry of Higher Education and Scientific Research for its support. The authors also thank the national dairy “Edough” of Annaba for their efforts and their implication in the manufacture of the butter and the realization of the analyses.

Conflict of interest

Authors declare no conflict of interest.

References

- Benmeziane-Derradji F, Djermoune-Arkoub L, Ayat NE, et al. Impact of roasting on the physicochemical, functional properties, antioxidant content and microstructure changes of Algerian lentil (Lens culinaris) flour. J Food Meas Charact. 2020;14:2840-2853. [Crossref][Googlescholar]

- Bunghez F, Socaciu C, Zagrean F, et al. Characterisation of an Aromatic Plant-based Formula using UV-Vis Spectroscopy, LC-ESI(+)QTOF-MS and HPLC-DAD analysis. Food Sci Technol. 2013;70(1):16-24. [Crossref]

- Caliskan G, Dirim SN. The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technol. 2016;287:308-314. [Crossref][Googlescholar]

- Cangussu LB, Fronza P, Franca AS, et al. Chemical characterization and bioaccessibility Assessment of Bioactive Compounds from Umbu (Spondias tuberosa A.) Fruit Peel and Pulp Flours. Foods. 2021;10(11):2597. [Crossref][Googlescholar][Indexed]

- Chiocchio I, Mandrone M, Tomasi P, et al. Plant secondary metabolites: an opportunity for circular economy. Molecules. 2021;26(2):495. [Crossref][Googlescholar][Indexed]

- Deb S, Kumar Y, Saxena DC, et al. Functional, thermal and structural properties of fractionated protein from waste banana peel. Food Chem X. 2022;13:100205. [Crossref][Googlescholar][Indexed]

- Falade OS, Otemuyiwa IO, Adekunle AS, et al. Nutrient composition of watermelon (Citrullis lanatus (Thnb.) Matsum. and Nakai) and egusi melon (Citrullus colocynthis (L.) Schrad.) seeds. Agric Conspec Sci. 2020;85(1):43-49. [Googlescholar]

- Fundo JF, Miller FA, Garcia E, et al. Physicochemical characteristics, bioactive compounds and antioxidant activity in juice, pulp, peel and seeds of Cantaloupe melon. J Food Meas Charact. 2018;12(1):292-300. [Crossref][Googlescholar]

- Ganjewala D, Boba S, Raghavendra AS, et al. Sodium nitroprusside affects the level of anthocyanin and flavonol glycosides in pea (Pisum sativum L. cv. Arkel) leaves. Acta Biol Szeged. 2008;52(2):301-305. [Googlescholar]

- Ibrahim ME, El-Masry HG. Phenolic content and antioxidant activity of cantaloupe (Cucumis melo var. cantalupensis) and food application. Int J Nutr Food Sci. 2016;5(1):16-24. [Crossref][Googlescholar]

- Kang OJ. Evaluation of melanoidins formed from black garlic after different thermal processing steps. Prev Nutr Food Sci. 2016;21(4):398-405. [Crossref][Googlescholar][Indexed]

- Koubala BB, Bassang’na G, Yapo BM, et al. Morphological and Biochemical Changes During Muskmelon (Cucumis melo var. Tibish) Fruit Maturation. J Food Nutr Sci. 2016;4(1):18-28. [Crossref][Googlescholar]

- Li D, Wang P, Luo Y, et al. Health benefits of anthocyanins and molecular mechanisms: Update from recent decade. Crit Rev Food Sci Nutr. 2017;57(8):1729-1741. [Crossref][Googlescholar][Indexed]

- Mallek-Ayadi S, Bahloul N, Kechaou N, et al. Characterization, phenolic compounds and functional properties of Cucumis melo L. peels. Food Chem. 2017;221:1691-1697. [Crossref][Googlescholar][Indexed]

- Manickavasagan A, Thangavel K, Dev SR, et al. Physicochemical characteristics of date powder produced in a pilot scale spray dryer. Dry Technol. 2015;33(9):1114-1123. [Crossref][Googlescholar]

- Martínez P, Peña F, Bello-Pérez LA, et al. Physicochemical, functional and morphological characterization of starches isolated from three native potatoes of the Andean region. Food Chem X. 2019;2:100030. [Crossref][Googlescholar][Indexed]

- Mehra M, Pasricha V, Gupta RK, et al. Estimation of nutritional, phytochemical and antioxidant activity of seeds of musk melon (Cucumis melo) and water melon (Citrullus lanatus) and nutritional analysis of their respective oils. J Pharmacogn Phytochem. 2015;3(6):98-102. [Googlescholar]

- Miller FA, Fundo JF, Garcia E, et al. Physicochemical and bioactive characterization of edible and waste parts of “Piel de Sapo” Melon. Horticulturae. 2020;6(4):60. [Crossref][Googlescholar]

- Noor AA, Siti NM, Mahmad NJ, et al. Chemical composition, antioxidant activity and functional properties of mango (Mangifera indica . Var perlis sunshine) peel flour (MPF). Appl Mech Mater. 2015;754:1065-1070. [Crossref][Googlescholar]

- Dias PG, Sajiwanie JW, Rathnayaka RM, et al. Chemical composition, physicochemical and technological properties of selected fruit peels as a potential food source. Int J Fruit Sci. 2020;20(2): 240-251. [Crossref][Googlescholar]

- Dias P, Sajiwanie J, Rathnayaka RM, et al. Optimization of composite fruit peel powder as a texture modifier for fat free set yoghurt: A mixture design approach. J Agric Sci. 2021;16(2):226-236. [Crossref][Googlescholar]

- Parmar HS, Kar A. Protective role of Mangifera indica, Cucumis melo and Citrullus vulgaris peel extracts in chemically induced hypothyroidism. Chem Biol Interact. 2009;177(3):254-258. [Crossref][Googlescholar][Indexed]

- Pestana JM, Puerta B, Santos H, et al. Impact of dietary incorporation of Spirulina (Arthrospira platensis) and exogenous enzymes on broiler performance, carcass traits and meat quality. Poult Sci. 2020;99(5):2519-2532. [Crossref][Googlescholar][Indexed]

- Qian OY, Harith S, Shahril MR, et al. Bioactive compounds in Cucumis melo L and Beneficial health effects: a scoping review. Malays Appl Biol. 2019;48(4):1-13. [Googlescholar]

- Raza N, Arshad MU, Anjum FM, et al. Impact of drying methods on composition and functional properties of date powder procured from different cultivars. Food Sci Nutr. 2019;7(7):2345-2352. [Crossref][Googlescholar][Indexed]

- Rolim PM, Fidelis GP, Padilha CE, et al. Phenolic profile and antioxidant activity from peels and seeds of melon (Cucumis melo L. var. reticulatus) and their antiproliferative effect in cancer cells. Braz J Med Biol. 2018;51(4): 6069, [Crossref][Googlescholar][Indexed]

- Rolim PM, Seabra LM, de Macedo GR, et al. Melon by Products: Bio potential in Human Health and Food Processing. Food Rev Int. 2019;36(1):15- 38. [Crossref][Googlescholar]

- Chia SL, Chong GH. Effect of Drum Drying on Physico chemical Characteristics of Dragon Fruit Peel (Hylocereus polyrhizus). Int J Food Eng. 2015;11(2):1-9. [Crossref][Googlescholar]

- Sass-Kiss A, Kiss J, Milotay P, et al. Differences in anthocyanin and carotenoid content of fruits and vegetables. Food Res Int. 2005;38(8-9):1023-1029. [Crossref][Googlescholar]

- Sidlagatta V, Dasi SD, Chilukuri SVV, et al. Effect of Maltodextrin concentration and inlet air temperature on properties of spray dried powder from reverse osmosis concentrated sweet orange Juice. Braz Arch Biol Technol. 2020;63: 20190538. [Crossref][Googlescholar]

- Silva MA, Albuquerque TG, Alves RC, et al. Cucumis melo L. Pulp and by Products: Nutritional and Antioxidant Potential. Curr Dev Nutr. 2021;5(Suppl 2):570. [Crossref][Googlescholar][Indexed]

- Suresh C. Assessment of functional properties of different flours. Afr J Agric Res. 2013;8(38):4849-4852. [Googlescholar]

- Weng M, Li Y, Wu L, et al. Effects of passion fruit peel flour as a dietary fibre resource on biscuit quality. Food Sci Technol. 2020;41(2):1-9. [Crossref][Googlescholar]