Short commentary

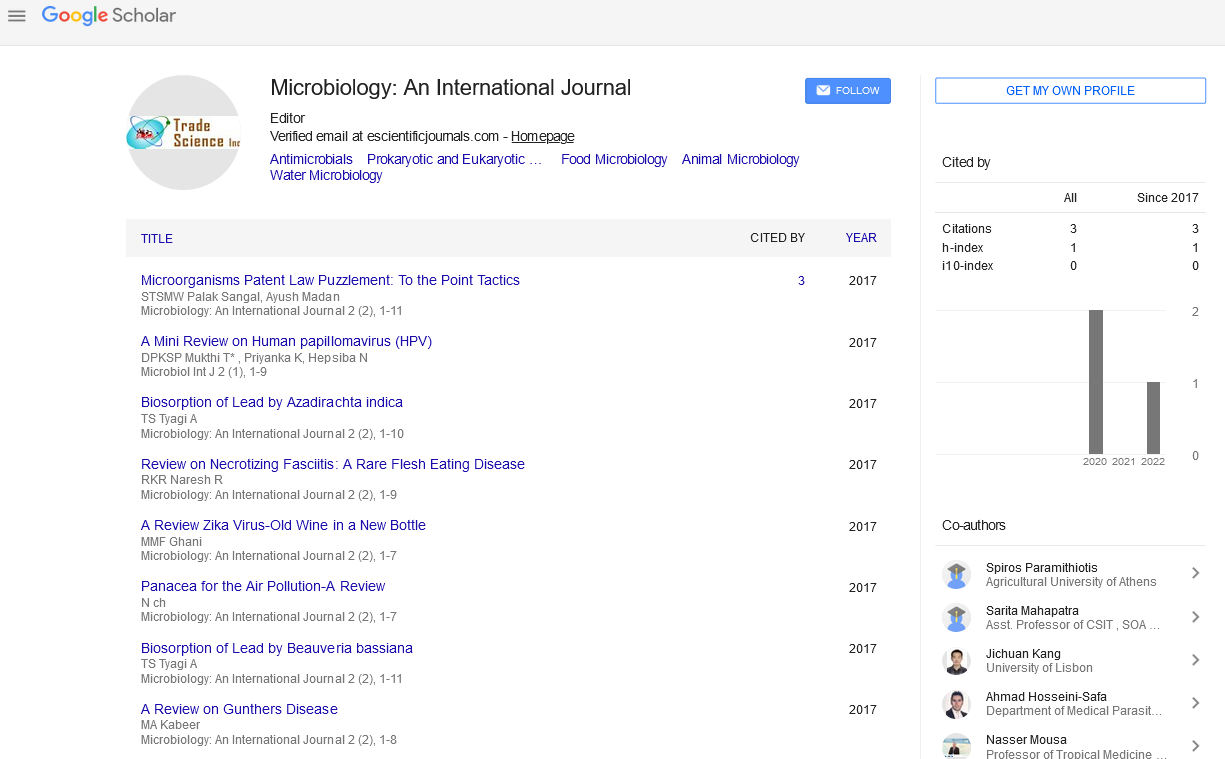

, Volume: 3( 3)Machine Learning-Related Techniques for Assessing Microbiological Spoilage Associated with Ready-to-Eat Leafy Vegetables Using Different Techniques

- *Correspondence:

- Lech Roszko, Department of Food Technology and Food Evaluation, Warsaw University of Life Sciences, Poland, E-mail: lech.r.@tropmedres.ac

Received: November 29, 2021; Accepted: December 13, 2021; Published: December 20, 2021

Citation: Lech Roszk. Machine Learning-Related Techniques for Assessing Microbiological Spoilage Associated with Ready-to-Eat Leafy Vegetables Using Different Techniques. Microbiol Int J. 3(3):131.

Abstract

The purpose of this study was to package using different techniques (AP, HiO2MAP, or VP) during storage under different conditions (refrigerator room or display case) for microbiological correlation. It was to determine the biogenic amine (BA) formed in chicken breast. Evaluate the quality of chicken with BA formation (TPC, LAB, Pseudomonas aeruginosa and Enterobacteria), and the compatibility of Bioamines selected as indicators of chicken spoilage. The initial TPC of chicken fillet was 2.57 to 3.04 log CFU / g. Over time, a systematic significant (p ≤ 0.05) increase was observed until TPC exceeded 7.5 log CFU / g (AP and VP, display case) on day 9. Regardless of packaging technology and storage conditions, Cadaverine and tyramine were shown to be quantitatively predominant in chicken fillets (166.00 mg / kg in showcase MAP meat in day 9 refrigerator AP meats, 175.03 mg / kg on day 9).

Keywords

Enterobacteria; Technology; Cadaverine; Bioamines; Quantitative

Introduction

World poultry production has grown rapidly over the last 50 years, and poultry meat is now the most widely consumed variety of meat in the world. The desire to increase poultry production and extend its shelf life has prompted the search for new methods of quality assessment [1]. The assessment of chicken quality is primarily based on its sensory and microbiological properties. However, instead of microbiological analysis, certain chemical indicators such as qualitative and quantitative analysis of bioamine may be determined as indicators of food safety and quality assessment [2]. Packaging techniques, for example involving refrigerated storage in a vacuum or conditioned atmosphere, are now widely used to extend the shelf life of meat. Bioamines are low molecular weight organic bases. They have aliphatic, aromatic or heterocyclic structures [3].

In foods, BA is formed primarily by decarboxylation of amino acids under the influence of endogenous or bacterial enzymes. At high concentrations, BA can pose a toxicological danger to human health. For example, taking large amounts of histamine and tyramine with food can cause migraine headaches, food intolerance, or high blood pressure. BA occurs naturally in foods and is usually low in concentration, and elevated levels may be due to the action of endogenous and bacterial enzymes during food storage or processing. The formation of BA in food is influenced by many factors that affect raw materials, processing and storage techniques, and microbiological quality. The increased risk of BA formation is associated with products in which microorganisms are found that have the ability to biosynthesize their precursors, free amino acids, and the enzymes that catalyze their decarboxylation. Therefore, due to its high content of free amino acids and a suitable environment for bacterial growth, poultry meat can be a source of BA in the human diet when overdose. Elevated levels of some BAs in foods may also indicate poor microbiological quality in foods containing meat. Increased BA content of food in storage can be used to assess the deterioration process of food. Fresh meat naturally contains supermini and spermidine [4].

During storage, the content of histamine, Cadaverine, putrescine, tyramine increases, the sperm content decreases slightly, and spermidine levels remain stable. The BA content of chilled poultry depends, among other things, on the type and breeding of the bird, the type of muscles, and the packaging technique. Therefore, it is not easy to create a general indicator that reliably predicts poultry quality based on BA content. Many indicators have been proposed in the literature to assess the extent of poultry spoilage, including Cadaverine and tyramine, putrescine and Cadaverine concentrations, or total Cadaverine, putrescine and Cadaverine concentrations, as well as histamine [5].

Conclusion

The results of studies on the impact of packaging technology on the quality of poultry meat with respect to BA content and microbial contamination are not definitive. Therefore, the objectives of this study are to determine BA formed in chicken breast packaged with different techniques during storage under different conditions, BA formation of microbiological quality of chicken. It was to correlate with. Assess the suitability of BA selected as an indicator of chicken spoilage.

References

- Algahtani FD, Morshdy AE, Hussein MA. Biogenic amines and aflatoxins in some imported meat products: Incidence, occurrence, and public health impacts. J Food Quality. 2020.

- Balamatsia CC, Paleologos EK, Kontominas MG. Correlation between microbial flora, sensory changes and biogenic amines formation in fresh chicken meat stored aerobically or under modified atmosphere packaging at 4 C: Possible role of biogenic amines as spoilage indicators. Antonie van Leeuwenhoek. 2006;89(1):9-17.

- Barbieri F, Montanari C, Gardini F. Biogenic amine production by lactic acid bacteria: A review Foods. 2019; 8(1):17.

- Gutierrez C, Somoskovi A, Natarajan K. Need for better adherence to optimal incubation temperature for quality laboratory diagnostics and antibiotic resistance monitoring.Afr JLabMed. 2018:7(2):1-2.

- Elsgaard L, Jørgensen LW. A sandwich-designed temperature-gradient incubator for studies of microbial temperature responsesJ Microbiol Methods. 2002;49(1):19-29.