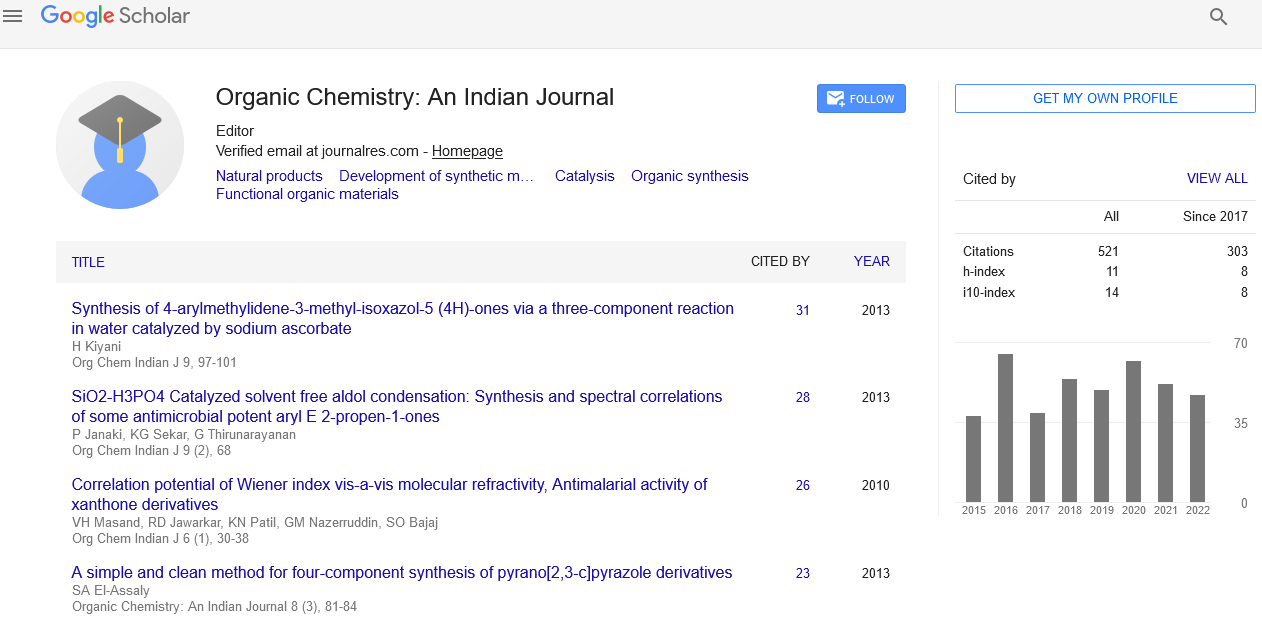

Short communication

, Volume: 15( 12)In The Chemical Industry, Plastic Waste is Used

Shane Ward*

- *Correspondence:

- Shane Ward

Editorial Office, Organic Chemistry: An Indian Journal, UK

E-Mail: organicchem@journalres.com

Received: December 15, 2021; Accepted: December 14, 2021; Published: December 21, 2021

Citation: Ward S. In The Chemical Industry, Plastic Waste is Used. Org Chem Ind J. 2021;15(12):59

Abstract

In the circular economy, wastes are considered useful feedstock since they may be utilised to generate fertilisers, fuels, chemicals, and a variety of packaging, housing, transportation, and apparel components. Plastics are accountable for a considerable amount of our society's waste today, which is a huge problem. Plastics are synthetic polymers that resist decomposition and, as a result, are prone to collecting in landfills or the environment when they are abandoned. Plastics' economic worth is lowered because not all of them can be reused. Plastics can discharge toxic substances that are hazardous to human health and the environment. Plastic products are pervasive in our daily lives, accounting for about 360 million tonnes of global plastic production in 2018, of which more than 60% were discarded. As a result, plastic contamination is important, resulting in microplastics being deposited in soil, seas, crustaceans, and rain.

Introduction

In the circular economy, wastes are considered useful feedstock since they may be utilised to generate fertilisers, fuels, chemicals, and a variety of packaging, housing, transportation, and apparel components. Plastics are accountable for a considerable amount of our society's waste today, which is a huge problem. Plastics are synthetic polymers that resist decomposition and, as a result, are prone to collecting in landfills or the environment when they are abandoned. Plastics' economic worth is lowered because not all of them can be reused. Plastics can discharge toxic substances that are hazardous to human health and the environment. Plastic products are pervasive in our daily lives, accounting for about 360 million tonnes of global plastic production in 2018, of which more than 60% were discarded. As a result, plastic contamination is important, resulting in microplastics being deposited in soil, seas, crustaceans, and rain.

Chemical conversion of plastic trash into reusable building blocks could help address these challenges while also reducing the chemical industry's carbon footprint. The method enhances the plastic recycling principle by requiring, first and foremost, the careful design of efficient and controlled depolymerization methods. Regardless of this stumbling block, putting in place strong plastics value chains based on recovery, reprocessing, and upgrading will be a practical method to turn a problem into an opportunity. A waste-to-products strategy is already in place for animal and plant biomass polymeric waste, where mature technologies are available. When discussing polymers in general, there aren't always clear definitions, which can lead to confusion between terminology that are commonly used but aren't interchangeable. For this objective, the IUPAC recommendations are a useful starting point.As a result, "degradation" is a general term that refers to the "progressive loss of a substance's performance or characteristics" as a result of chemical (acids, air, halogens, solvents) or physical agents (heat, light). Tensile strength, colour, and form are examples of polymer properties that can be altered by changing the chemical composition (e.g., as a consequence of oxidation, cross-linkage, bond cleavage). Biodegradation is described as "degradation caused by enzymatic processes as a result of cell action." While the term "biodegradable" is sometimes used to refer to artificial polymers, it refers to biorelated polymers (i.e., proteins, nucleic acids, and polysaccharides) that are "susceptible to degradation by biological activity by lowering of macromolecule molar masses". As a result, the terms "chain cleavage" and "degradation" are interchangeable in this context. To avoid ambiguity, we used the word "depolymerisation" instead of biogradation to describe the "process of transforming a macromolecule into (recoverable) monomers or a mixture of monomers" in this editorial. Another useful term is "bioplastic," which means "biobased polymer derived from biomass or issued from biomass monomers," where "biobased" means "composed or derived in whole or in part from biological products issued from biomass." Furthermore, since different issuers define "compostable" differently, there is no widely accepted term. The European Commission's EN 13432 report establishes "Packaging-Requirements, compostable and biodegradable packaging," as well as requirements including disintegration (material breakdown into defined-size particles), biodegradability, and the lack of negative impacts. The phrase "recycling" is a broad term with many different connotations depending on the year and author. Plastics manufacturers have also issued their own set of rules nicknamed "Design for Recycling." According to a widely accepted notion of plastic recycling, "the method of reclaiming scrap or waste plastics and reprocessing the material into useful objects, frequently radically different in shape from their initial state." Breaking down techniques by recycled polymer, finished product, or process distinguishes them even more, which can lead to inconsistencies and overlaps.