Original Article

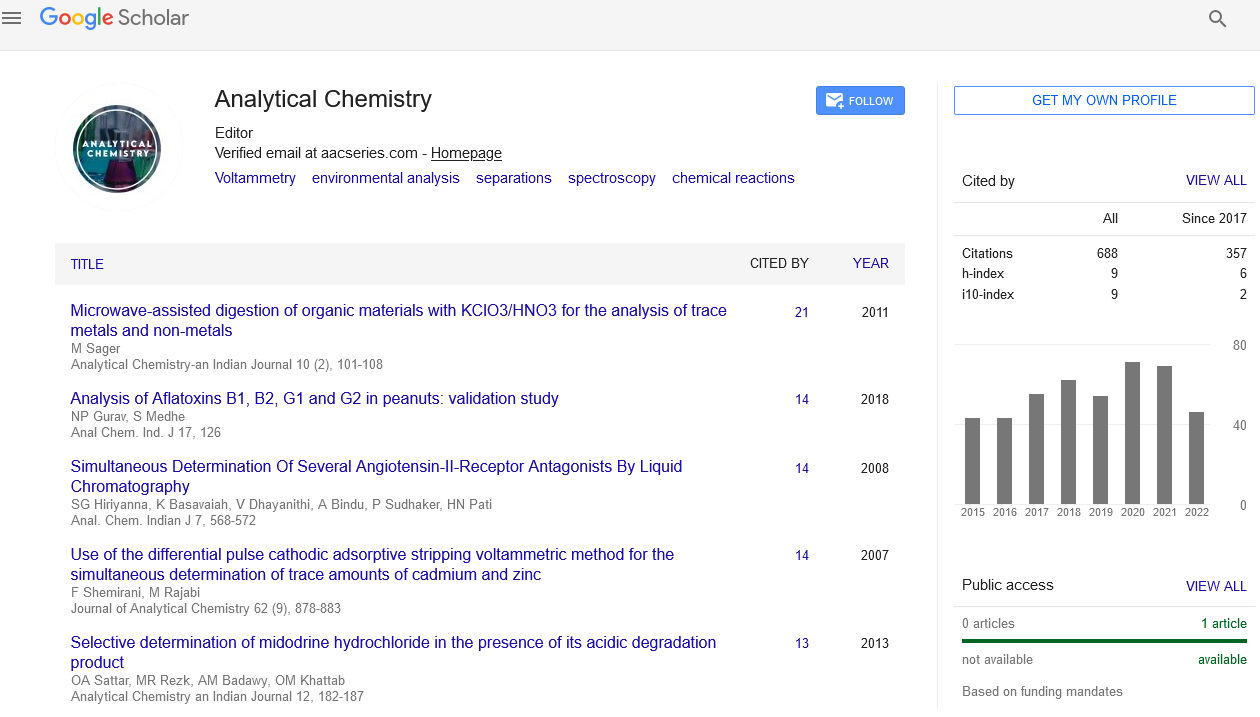

, Volume: 22( 11) DOI: 10.37532/0974-7419.2022.22(11).227immunosensor uses and advances in food analysis

- *Correspondence:

- Tim Jason Managing Editor, Analytical Chemistry: An Indian Journal, Belgium. , E-mail: timjason785@hotmail.com

Received: November 2, 2022, Manuscript No. tsac-22-84076; Editor assigned: November 4, 2022, PreQC No. - tsac-22-84076 (PQ); Reviewed: November 18, 2022, QC No. tsac-22-84076 (Q); Revised: November 20, 2022, Manuscript No tsac-22-84076 (R); Published date: November 22, 2022. DOI: 10.37532/0974-7419.2022.22(11).227

Citation: Jason T. Immunosensor Uses and Advances in Food Analysis. Anal Chem Ind J. 2022;22(11):227.

Abstract

The food sector is using ultrasonic techniques more and more for food analysis and food customization. Low-intensity ultrasound is a non-destructive method for learning about physicochemical characteristics such composition, structure, physical state, and flow rate. Using high-intensity ultrasound, food qualities can be changed chemically or physically. For instance, emulsions can be created, cells can be damaged, chemical reactions can be sped up, enzymes can be inhibited, meat can be made more tender, and crystallization processes can be changed. Ultrasonic techniques are being used more frequently in the food industry for food analysis customization and Atomisation. A non-destructive technique for discovering physicochemical properties like as composition, structure, physical state, and flow rate is low-intensity ultrasound. High-intensity ultrasound can modify the chemical or physical properties of food. For instance, it is possible to produce emulsions, harm cells, speed up chemical reactions, suppress enzymes, soften meat, and alter crystallization processes. The value of the ion-exchange mechanism in base retention and spends a significant amount of time on the HPLC of chemical bases.

Keywords

Beverage analysis; Biosensor; Food analysis; Pattern recognition; Sensor arrays

Introduction

For the purpose of guaranteeing food safety and quality, the analysis of foods to determine the presence of biological and chemical pollutants is a practice of vital relevance. The isolation and counting of live bacterial cells in food is accomplished using traditional bacterial testing techniques using certain microbiological media. Because they rely on microorganisms' capacity to grow and form visible colonies, traditional methods are highly sensitive and affordable but take several days to yield findings. For instance, the official method now in use to count Salmonella germs in food requires a number of laborious sequential culture stages that can take up to 4 days-5 days to complete. Pre-enrichment, selective enrichment, isolation, and, if presumed positive Salmonella colonies form, biochemical and serological confirmation are generally included in these processes.

A chemical sensor is a device that selectively reacts to a given analyte through a reversible chemical interaction and can be used to determine the analyte's quantity or quality. All sensors are made up of two primary parts: the selective chemistry takes place in the first, and the transducer is found in the second. One type of energy can be transformed into other thanks to the transducer. A signal is produced by a chemical reaction, such as a color change, fluorescence, the creation of heat, or a change in the crystal's oscillator frequency. The signal processing electronics and a signal display unit are additional components of a sensor. The principal components of a typical sensor

Despite the fact that e-tongues still deviate significantly from the normal taste sense, they have demonstrated strong correlations with the organoleptic ratings provided by human panelists. Comparing the two taste systems, artificial senses can be employed with a larger variety of samples and are not vulnerable to fatigue or infection (i.e., toxic samples). Additionally, etongues have the potential to be more sensitive than human tongues and are capable of detecting compounds that are invisible to their natural counterparts.

This is due to the fact that humans' taste systems are not as evolved as their olfactory systems. The electronic tongue, it has been noted, may be conceived of as equivalent to both olfaction and taste and it can be utilized for the detection of all types of dissolved substances, including volatile compounds which give aromas after evaporation.

Conclusion

Although they require a label, electrochemical immunosensors have better sensitivity than SPR and QCM as well as low-cost apparatus. They also have the primary advantages of being miniaturized and appropriate for in situ applications. Due to these benefits, the electrochemical method is more comparable to the spectrophotometric immunoassay and may be suggested as a replacement when ELISA is inapplicable with particular matrixes. The interferences that occasionally impair spectrophotometric measurement are actually insensitive to electrochemical detection. However, in this instance as well, examples based on this technology are only to be found in the research community and, to our knowledge, there are currently no commercial examples of electrochemical immunosensor kits available. The electrochemical method could offer quicker analysis times and equal sensitivity to the spectrophotometric immunoassay.