Original Article

, Volume: 15( 1)Feasibility Study on Enhancing the Properties of Subgrade Material using Waste Glass

- *Correspondence:

- Nirmala R Department of Civil Engineering, Sathyabama University, Chennai, Tamil Nadu, India, Tel: 044-24503151; E-mail: nirmala.civil@sathyabamauniversity.ac.in

Received: February 21, 2017 Accepted: March 07, 2017 Published: March 15, 2017

Citation:Nirmala R, Shanmugapriya M. Feasibility Study on Enhancing the Properties of Subgrade Material using Waste Glass. Int J Chem Sci. 2017;15(1):106.

Abstract

Generally, road pavement consists of various layers such as subgrade, sub-base, base and wearing course. These layers are prepared using the materials like aggregate, cement, soil and more. There are many modern methods used in stabilizing the weaker subgrade layer. The use of waste material is the most recommended method in the civil industry. Glass is one of the waste materials that can be used to enhance the soil subgrade properties. The glass powder is prepared by crushing the bottles. The various tests for soil are carried out in the laboratory to find out the properties of the field soil. From the test results, the optimum percentage of mix proportion of soil and glass is found out. It is inferred from the experimental study that replacing 40% of glass in the soil sample has high CBR value and also high shear strength compared to the field sample. Hence replacing 40% of glass in the soil gives a better quality of subgrade material, increases the subgrade stability and also it is an effective method of utilizing the waste glass.

Keywords

Pavement; Aggregate; Subgrade; Shear strength; Stability

Introduction

Now-a-days road construction increases the demand for materials which depletes the natural resources. Out of four layers in a pavement, Subgrade is the bottom layer and also it is important for the other layers to sustain their properties. The load is distributed uniformly through the layers from top to the bottom. As the subgrade consists of soil, its stability varies according to the environmental strata. There are many ways adapted in the present to enhance the properties of the soil. The use of waste products in enhancing the properties of the soil is a well versed method in the civil industry. The wastes are also piling up without a way for disposal. Approximately 42 million tons of solid waste are being generated in India every year. Among the waste material, Glass is one of the alternative material that can be used in subgrade to increase the soil stability. The main objective of the study is to determine the optimum percentage of glass to be replaced with subgrade soil. This study mainly focuses to improve the bearing capacity and shear strength of the subgrade soil and also to use the waste glass in an efficient way.

Various researches have been carried out to study the performance of waste glass replaced in soil/aggregates. Blewett [1] stated that the use of glass in crushed powder (Figure. 1) form showed the great advantages in terms of strength as well as in cost. Ahirrao et al. [2] had researched on eco-friendly pavement blocks made of waste glass, fly ash and dust. The compressive strength and flexural strength of pavement block is increased by 37% and 50% respectively. Also it was observed that 20% waste glass in replacement of sand to make concrete paving block gives acceptable mechanical properties. Ghasemi et al. [3] had done laboratory studies on recycled glass powder used as an additive in the asphalt binders. It was found that there were an improvement in Marshall Stability, mechanical properties, stiffness, tensile strength and thermal sensitivity. Myint win bo et al. [4], Nebojsa Davidovic et al. [5] and Arulrajah et al. [6] had researched waste glass as an additive to clayey material in subgrade and embankment of road pavement. It was concluded from the study that the sample mixture made of 80% clay material and 20% crushed waste glass can be used in pavements construction. Younus Ali [7] tested about geotechnical characteristics of recycled glass in road pavement application. The results of CBR test indicates that RCC blends with a higher recycled glass which would potentially reduce their soaked CBR values. All the studies stated that use of waste glass as an alternate material does not shows the negative effects when mixing with soil as a subgrade material. The study mainly concentrated on determining the geotechnical properties of clay with the addition of waste glass powder and also assessing the suitability of mixture as subgrade material [8].

Material Description

Soil

The soil sample for this study is obtained from a worksite at Pallavaram, Chennai. The soil is of clayey nature and was in a semi dry condition at the time when it was collected. Table 1 describes the properties of the soil.

| Soil Properties | Values |

|---|---|

| Specific gravity (Gs) | 2.68 |

| Liquid limit | 33% |

| Co efficient of curvature | 0.95 |

| Uniformity co efficient | 4.2 |

| Plastic limit | 31% |

| Plasticity index | 23% |

| Permeability | 0.138 cms |

Table 1. Test properties of soil sample.

Glass

The type of Glass materials used in the study is soda lime glass which was collected as waste glass bottles from the shops. The collected bottles are cleaned by soaking in water to remove chemicals and stickers. Collected glass bottles are crushed and glass powder was sieved through 300 micron sieve. The properties of the glass are given in Table 2.

| Properties | Values |

|---|---|

| Coefficient of Expansion | 32.5 × 10-7 cm/cm/°C |

| Strain Point | 510°C |

| Soften Point | 821°C |

| Density | 2.23 g/cm3 |

| Young’s Modulus | 6.4 × 103 Kg/mm2 |

Table 2. Properties of glass.

Mix proportion of test sample

The samples are made into 6 possible proportions;

Proportion of sample

Clay 100% and Glass 0% C100 G 0

Clay 80% and Glass 20% C80 G 20

Clay 75% and Glass 25% C75 G 25

Clay 70% and Glass 30% C70 G 30

Clay 65% and Glass 35% C65 G 35

Clay 60% and Glass 40% C60 G 40

Clay 55% and Glass 45% C55 G 45

Experimental studies

Proctor compaction test

Proctor compaction is done to find out the optimum moisture content of the soil. Dry density, Wet density, void ratio and Porosity also can be found out using this test. Table 3 shows the proctor compaction test values for both soil and glass samples.

| Proportion of Sample | Max Dry Density (g/cc) | Optimum Moisture Content % | Void Ratio | Porosity |

|---|---|---|---|---|

| C100 G0 | 1.92 | 13 | 1.37 | 0.57 |

| C80 G20 | 1.903 | 13 | 1.39 | 0.58 |

| C75 G25 | 1.931 | 11 | 1.41 | 0.58 |

| C70 G30 | 1.938 | 11 | 1.41 | 0.58 |

| C65 G35 | 1.934 | 9 | 1.42 | 0.59 |

| C60 G40 | 1.936 | 9 | 1.46 | 0.59 |

| C55 G45 | 1.824 | 7 | 1.40 | 0.58 |

Table 3. Proctor compaction test values of various proportions of soil and glass samples.

The maximum dry density of the clay soil is 1.92 g/cc. The increase in glass content in the soil sample increases the maximum dry density [9]. The dry density reaches the stabilization point at 40% replacement of glass in the soil sample.

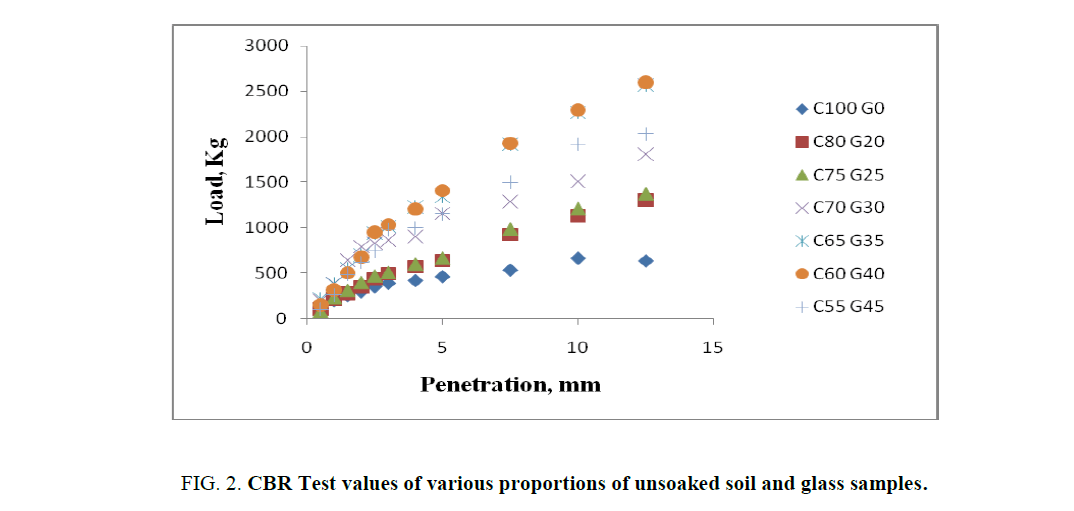

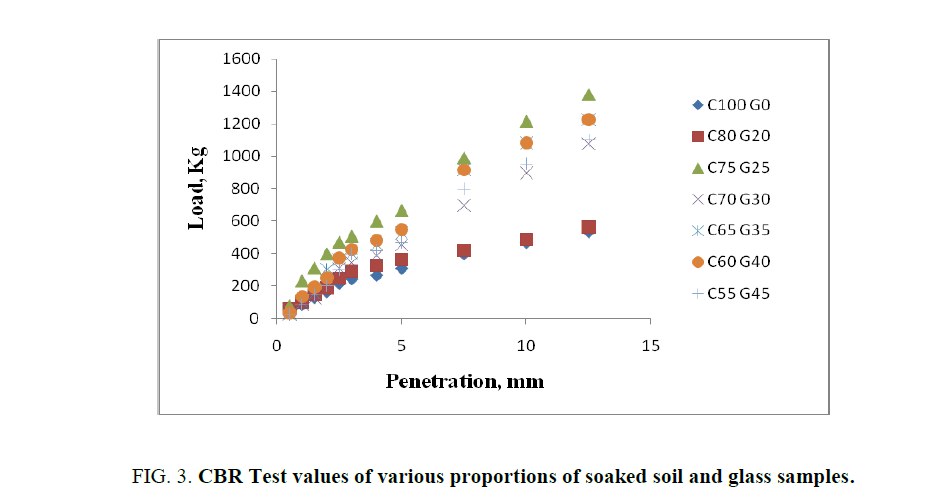

California bearing ratio test

The California Bearing Ratio test is a penetration test carried out for the evaluation of subgrade strength of roads and pavements [10,11]. The results obtained by these tests are used with the empirical curves to determine the thickness of flexible pavement and its component layers. The test has been carried out in unsoaked and soaked condition of samples to determine the good and worst conditions of soil.

Figure. 2 shows the graphical representation of load versus penetration values of the samples in different proportions of soil and glass under unsoaked condition. It has been noted that increase in glass content with the soil increases the load carrying capacity of the sample. The 40 percentage of glass in the soil sample takes the highest load of 2700 kg.

Figure. 3 indicates that the bearing capacity of 60% of soil and 40% of glass is found to be higher than the other proportions of sample under soaked condition.

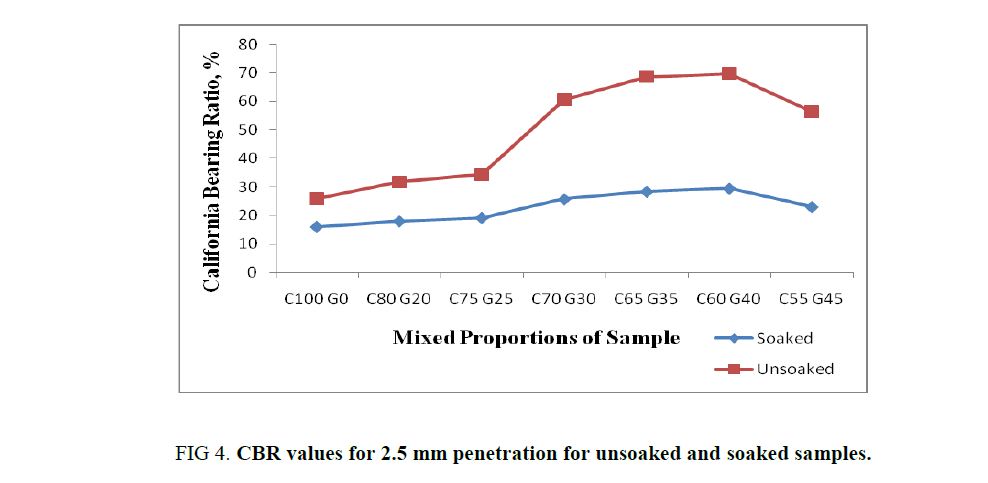

It is observed from Figure. 4 that the CBR value of the unsoaked condition of sample of 100% clay with no replacement of glass is 25.86% and this value increases with the consequent increase in percentage of glass with the soil. The sample having 40% glass powder has the highest CBR value among the other proportions of soil and glass.

The result of the soaked CBR test shows that the CBR value of the 100 percentage of clay with no replacement of glass is 15.89%. The CBR value of the samples increases as the replaced glass percentage increases. The sample having 40% glass has the highest CBR value among the other samples.

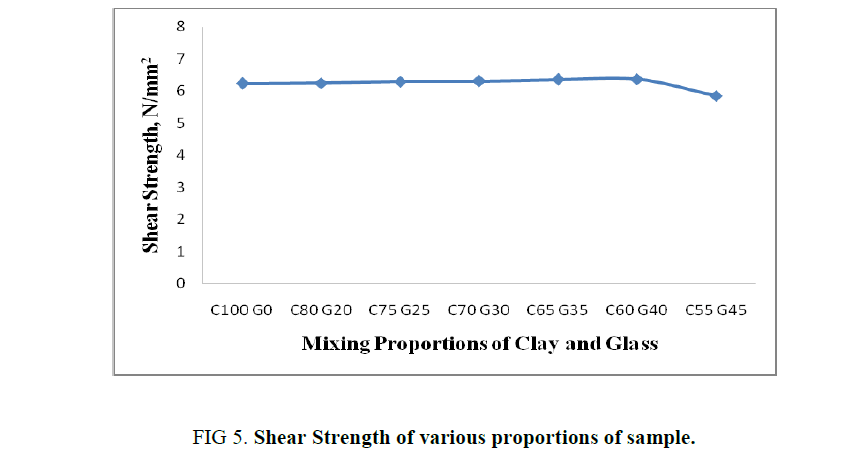

The vane shear test is an in-situ geotechnical testing methods used to estimate the undrained shear strength of fully saturated clays without disturbance. This test is useful for soils of low shear strength for which triaxial or unconfined tests cannot be performed (Figure. 5).

Shear strength of the soil is 6.23 N/mm2 without the replacement of glass in the soil. The shear strength increases when the percentage of replacement of glass percentage gradually increases. It has been observed that the soil sample with replaced glass percentage of 40 gives the highest shear strength of 6.37 N/mm2.

Conclusion

The following conclusions were drawn from the study of properties of soil with the replacement of glass;

• It is inferred that glass can be replaced up to 40% in soil to increase its bearing strength for both unsoaked sample and the soaked sample.

• It is inferred that adding glass as a replacement for 40% also increases the shear strength of clay.

• It is concluded that the stabilization of soil in the subgrade layer can be done by replacing upto 40% glass is the critical value of waste glass which contributes to improve the geotechnical properties.

Based on the test results from the experimental study, it is concluded that the use of waste glass as a subgrade material does not have negative impact on geotechnical and mechanical properties of mixture. The addition of waste glass not only increases the shear strength, also improves the resistivity of soil against deformation of imposed loads. Previous researchers suggested only 30% of addition of glass with clay. The present study proves that waste glass can be added upto 40% gives a better strength and binding properties with clay.

Acknowledgment

The authors are grateful to the management of Sathyabama University for providing laboratory and library facilities to perform the study.

References

- Blewett J, Woodward PK. Some geotechnical properties of waste glass in Ground Engineering. 2000.

- Ahirrao SP, Borse KN, Bagrecha S. Eco-friendly pavement blocks of waste glass fly ash and dust. International Journal of Civil, Structural Environmental and Infrastructure Engineering Research and Development 2013;3:75-8.

- Ghasemi M, Marandi SM. Laboratory studies of the effect of recycled glass powder additive on the properties of polymer modified asphalt binders?. IJE Transactions A: Basics 2013;26:1183-90.

- Bo MW, Arulrajah A. Use of recycled waste in highway construction?. 3rd International Conference on Geotechnical Engineering for Disaster Mitigation and Rehabilitation combined with the 5th International Conference on Geotechnical and Highway Engineering: Practical Applications, Challenges and Opportunities, Semarang, Indonesia. 2011;263-70.

- Davidovic N, Bonic Z, Prolovic V. Waste glass as additive to clayey material in subgrade and embankment of road pavement. Architect Civil Eng. 2012;10:215-22.

- Arulrajah A, Ali MMY, Disfani MM, et al. Recycled glass blends in pavement base/subbase application. J Mater Civil Eng. 2013;26:1-38.

- Younus Ali MM. Geotechnical characteristics of recycled glass in road pavement. Australian Geomechanics 2012;46:113-22.

- Bob F, Hogan F. Use of glass in pavement aggregate, 23rd ARRB conference-research partnering with practitioners, Adelaide, Australia 2008;1-8.

- Jasim AA. Using waste glass as secondary aggregates in asphalt mixtures. Int J Adv Res. 2013;2:41-6.

- Disfani MM. Sustainable use of recycled glass bio solids blends in road applications. Australian Geomech J. 2011;44:65-72.

- Thanaya NA. ?Hot Asphalt Pavement Mixtures incorporating all Waste Materials?. Media Meknik Sipil. 2007;1-6.