Original Article

, Volume: 15( 4)Evaluation of Biodegradation of Low Density Polyethylene (LDPE) Using Hibiscus Mucilage as a Green Polymers

- *Correspondence:

- Sanjay K Sharma , Green Chemistry and Sustainability Research Group, Department of Chemistry, JECRC University, Jaipur, India, Tel: 9416808666; E-mail: sk.sharmaa@outlook.com

Received: August 10, 2017; Accepted: August 29, 2017; Published: September 01, 2017

Citation:Ramkesto K, Sanjay KS. Evaluation of Biodegradation of Low Density Polyethylene (LDPE) Using Hibiscus Mucilage as a Green Polymers. Int J Chem Sci. 2017;15(4):187

Abstract

The durability and resistance to degradation of plastics have generated a disposal problem in the environment. In this study, biodegradability of low density polyethylene (LDPE) with Hibiscus mucilage was studied. Samples with different concentrations of Hibiscus mucilage (as 5%, 10%, 15%, 20% and 25%) were prepared. Glycerol as a plasticizer and Fe2SO4 as a pro-oxidant are used. The effect of mucilage concentrations on the mechanical properties (tensile strength and elongation), melt flow rate and density of the blended materials were studied. The biodegradation of the blends in soil was studied as a weight loss after two, four and six months. The results shown that with increase of mucilage content the biodegradability of the blends increased. The biodegradation of the samples in soil burial after six months revealed that the weight of the blends decreased with the increase of mucilage concentrations.

Keywords

Biodegradable polymers; Biodegradation; LDPE; Green polymers; Plastics

Introduction

The durability and resistance to all kind of degradation properties made the plastics widely accepted and that have generated a disposal problem in the environment, which is now become the field of interest for polymer researchers. It is common recognition that low density polyethylene is biologically inert, that is these are highly resistant to assimilation by microorganisms such as fungi, bacteria and similar kind of microorganisms [1]. Recycling of plastic is considered as a solution of disposal problem, but recycling is not applicable on all kinds of plastics [2]. Recycling of plastic is also limited to number of times as it loses their properties with number of times of recycling. Advancement in technology for physical, energetic and chemical recycling of plastics waste is developing side by side [3].

Investigating the biodegradable plastics can be considered as one of the most possible way to solve the solid waste problem. Blending of synthetic polymers with natural polymers such as starch, cellulose, lignin, chitin and chitosan is applied as a significant way to enhance polymer degradation in natural environments [4]. The blended polymer is a category of materials in which two or more polymers are mixed together to develop a new material with distinguish physical and chemical properties. The goal of blending two or more polymers is to get the synergetic effect in the blend [5]. Mucilage is physiological products [6]. Mucilage is a polysaccharide mixture [7]. The mucilage was extracted from leaves of Hibiscus rosa-sinensis (China rose) of Malvaceae family were collected from Bandel area of Hooghly district (West Bengal, India). The Hibiscus mucilage contains L-rhamnose, D-galactose, D-galactouronic acid and D-glucuronic acid [8].

In the present study, the blends of low density polyethylene (LDPE) and mucilage of different concentrations were prepared. Mechanical and physical properties of the blends were determined by standard test methods. In addition, the biodegradation in soil were also evaluated. The soil of Amanishah drain of Sitapura area, Jaipur and garden soil was taken to bury the samples. The overall objective of the present study was to evaluate the effect of different concentrations of mucilage on biodegradability of low density polyethylene (LDPE).

Materials and Methods

Materials

Low density polyethylene (grade 16MA400) produced by high pressure process was obtained from Reliance Polymers, India. Mucilage powder was extracted from the leaves of Hibiscus rosa-sinensis (China rose). Glycerol about 98% purified of Merk Co. Germany was used as a plasticizer. Fe2SO4 hydrated crystal purified of Merk Co. Germany was used as pro-oxident.

Methods

Mucilage powder plasticized with equal volume of glycerol, Fe2SO4 (1 wt% of LDPE) mixed in it manually. The samples were processed with different concentrations (5%, 10%, 15%, 20% and 25%) of mucilage in two roll mills at 150°-160°C for 10 min to 12 min. Sample sheets of 0.3 mm thickness were prepared by using compressor molding under heat and pressure. One sample sheet of virgin LDPE was prepared to be used as a reference standard.

The tensile strength and elongation at break were determined by using tensile testing machine (H10K, Tinius Olsen) as per standard test method ASTM D 638. The test was carried out at a speed of 50 mm/min. The mean values of three specimens for each concentration were reported.

The melt flow rates of the samples of different concentrations were measured at 190°C temperature and 2.16 kg load as per standard test method ASTM D 1238 by using melt flow indexer (Modular 7027, Ceast, Italy). The density of the samples was determined ass per standard test method ASTM D 792 by using density apparatus (Mettler Toledo, Japan).

Samples cut into strip shape and buried in soil for six months. Samples were weighted before soil burial. At the end of second, fourth and sixth months, samples were removed from soil and weighted.

Results and Discussion

The results of tensile strength and elongation of the investigated sheets, before and after the soil burial has been reported in TABLE 1. It was found that the tensile strength and elongation had decreased with the increase of concentration of mucilage.

| Strips of LDPE and mucilage with different concentrations | Tensile (MPa) | Elongation (%) | ||||

|---|---|---|---|---|---|---|

| Before | After | % Decrement | Before | After | % Decrement | |

| LDPE 100% | 10 | 9.8 | 2 | 40 | 38.9 | 2.8 |

| 5% Mucilage | 9.1 | 8.6 | 5.5 | 22.6 | 19.4 | 14.2 |

| 10% Mucilage | 8.7 | 8.1 | 6.9 | 20.6 | 15.7 | 23.8 |

| 15% Mucilage | 7.2 | 7.1 | 1.4 | 18.5 | 13.6 | 26.5 |

| 20% Mucilage | 6.8 | 6.0 | 11.8 | 16.8 | 10.3 | 38.7 |

| 25% Mucilage | 5.8 | 5.1 | 12.1 | 15.7 | 7.2 | 54.1 |

TABLE 1. Tensile strength and elongation before and after soil burial.

It was found that the decrease in tensile strength and elongation of reference standard sheet (virgin LDPE sheet) were negligible. It’s a strong predictor of degradation in soil.

The test results of melt flow rate of the materials, before and after soil burial reported in TABLE 2. The comparative study of the test results of melt flow rate before and after the soil burial expressed that a lot of change in molecular structure of the materials was occurred due to soil biodegradation. The distinguished change in flow properties of the materials was observed. It was found that there was no change in melt flow rate of standard reference material (virgin LDPE).

| Strips of LDPE and mucilage with different concentrations | Melt flow rate (gms/min) | ||

|---|---|---|---|

| Before | After | % Deviation | |

| LDPE 100% | 30 | 30 | 0.0 |

| 5% Mucilage | 36 | 32 | 11.1 |

| 10% Mucilage | 39 | 29 | 25.6 |

| 15% Mucilage | 43 | 25 | 41.9 |

| 20% Mucilage | 48 | 23 | 52.1 |

| 25% Mucilage | 52 | 18 | 65.4 |

TABLE 2. Melt flow rate before and after soil burial.

The test results of density of the materials, before and after soil burial has reported in TABLE 3. The density of the material was decreased significantly with the increase of concentrations of mucilage. The density of the blended materials after soil burial was reduced even less than the carrier resin (LDPE). It shows the biodegradation of polymeric materials in soil.

| Strips of LDPE and mucilage with different concentrations | Density (gm/cc.) | ||

|---|---|---|---|

| Before | After | % Deviation | |

| LDPE 100% | 0.918 | 0.918 | 0 |

| 5% Mucilage | 0.946 | 0.92 | 2.7 |

| 10% Mucilage | 0.976 | 0.908 | 7 |

| 15% Mucilage | 0.994 | 0.904 | 9.1 |

| 20% Mucilage | 1.011 | 0.9 | 11 |

| 25% Mucilage | 1.023 | 0.877 | 14.3 |

TABLE 3. Density before and after soil burial.

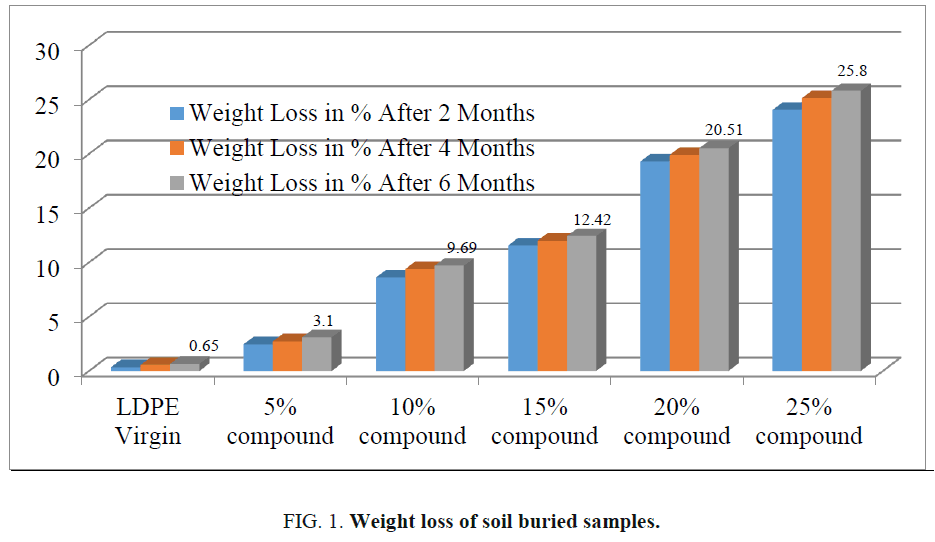

The influence of soil burial duration on weight loss of the blends has reported in TABLE 4 and also shown in FIG. 1 for two, four and six months. The weight loss of blended polymer sheets during biodegradation in soil indicates the amount of degradation in natural environment. The buried samples were attacked by soil microorganisms. The surface of the samples observed rough after removing from soil, which indicated that the content of mucilage was consumed by soil microorganisms. The negligible change in weight loss of standard reference sheet (virgin LDPE-100%) expressed that no attack made by soil microorganism.

| Strips of LDPE and mucilage with different concentrations | Weight loss after 2 months burial (%) | Weight loss after 4 months burial (%) | Weight loss after 6 months burial (%) |

|---|---|---|---|

| LDPE 100% | 0.35 | 0.55 | 0.65 |

| 5% Mucilage | 2.45 | 2.73 | 3.10 |

| 10% Mucilage | 8.60 | 9.38 | 9.69 |

| 15% Mucilage | 11.55 | 11.98 | 12.42 |

| 20% Mucilage | 19.3 | 19.90 | 20.51 |

| 25% Mucilage | 24.05 | 25.13 | 25.80 |

TABLE 4. Weight loss of soil buried samples.

Conclusion

In soil, the blended plastics degraded under the influence of soil microorganisms. Blending of mucilage with synthetic plastics is a possible way to make it biodegradable. The article describes studies on biodegradation of LDPE/mucilage blends. It was illustrated that the blending of mucilage significantly accelerated the biodegradation of material in natural environment. Indeed, the material examined underwent rapid biodegradation, but the course of material used as a green/natural polymer to increase the rate of biodegradation, is totally different from the previously used natural polymers. Here we can say that mucilage is a very good enhancer, initiator and propagator for the biodegradation of plastics. In our opinion, the LDPE and mucilage blends can be used in the production of environmentally degradable plastics.

Acknowledgements

The authors are thankful to Central Institute of Plastics Engineering and Technology (CIPET), Jaipur to make available their laboratory facilities for this study.

References

- Wiles DM, Scott G. Polyolefins with controlled environmental degradability. Polymer Degradation and Stability. 2006;91:1581-92.

- Khoramnejadian S. Converting non-biodegradable plastic to biodegradable by using natural polymer to help environment conservation. J Food Agri Env. 2011;9(2):477-9.

- Sharma SK, Ackmez M. A Handbook of Applied Biopolymer Technology, Synthesis, Degradation and Application. UK: Thomas Graham House, Science Park, Milton Road, Cambridge CB40WF, UK, Royal Society of Chemistry. 2011;pp:332.

- Bikaris D, Panayiotou C. LDPE/starch blends compatibilized with PE-g-MA copolymers. J Appl Pol Science. 1998;70:1503-21.

- Makhijani K, Kumar R, Sharma SK. Biodegradability of blended polymers: A comparison of various properties. Crit Rev Environ Sci Technol. 2015;45(16):1801-25.

- Darekar A, Kahane J. Plant extrudates and mucilage as pharmaceutical excipients. J Adv Pharm Edu Res. 2013;3(4):387-402.

- Gupta S, Parvez N, Sharma PK. Extraction and characterization of Hibiscus rosa-sinensis mucilage as pharmaceutical adjuvant. World Appl Sci Journal. 2015;33(1):136-41.

- Prabakaran L, Murthy VSN, Karpakavalli M. Extraction and characterization of Hibiscus rosa-sinensis mucilage for pharmaceutical applications. RGUHS Journal of Pharmaceutical Sciences. 2011;1(3):232-8.