Research

, Volume: 21( 1)Characterization of Aluminium 6013/Red Mud Composite Materials by Salt Spray Test

- *Correspondence:

- KN Chandrashekara

Department of Chemistry,

SJC Institute of Technology,

Chikkballapur, Karnataka,

India

Tel: 9591549884

E-mail: chandrasjcit2014@gmail.com

Received: October 28, 2022, Manuscript No. TSIJCS-22-78524; Editor assigned: October 31, 2022, PreQC No. TSIJCS-22-78524 (PQ); Reviewed: November 14, 2022, QC No. TSIJCS-22-78524; Revised: January 09, 2023, Manuscript No. TSIJCS-22-78524 (R); Published: January 16, 2023, DOI: 10.37532/0972-768X.23.21(1).430

Citation: KN Chandrashekara, Sreenivasa K, PV Krupakara. Characterization of Aluminium 6013/Red Mud Composite Materials by Salt Spray Test. Int J Chem Sci. 2023;21(1):430

Abstract

Composites have been in demand over the last twenty years for their better mechanical properties and corrosion resistance. In this publication, composites fabricated by liquid melt metallurgy techniques using aluminum 6013 as the matrix and red mud particles as reinforcements are subjected to salt spray tests and characterized by salt spray tests. Pre weighed samples of matrix and composites are placed in a salt spray chamber and continuously sprayed with a 5% sodium chloride solution for over 72 hours. Samples were periodically checked for surface damage. Samples were found to show no damage up to 48 hours. At the end of the experiment the damage to the matrix was greater than the composite. Composites are therefore more suitable than matrix alloys for applications where marine environments are present.

Keywords

Aluminium 6013; Red mud; Salt spray; Corrosion resistance; Fabricated

Introduction

6000 series aluminum alloys are popular for their wide range of applications in engineering due to their increased strength to weight ratio [1]. The mechanical and corrosion properties can be tailored by converting the alloys into composites by the addition of different reinforcements like titanium di boride, quartz, beryl, silica, alumina and hematite ore [2-7].

T Sathishm, et al. conducted salt spray tests on titanium nitride and zirconia reinforced AA8079 alloys [8]. They ran the tests for a wide range of times from 24 hours to 96 hours at 24 hours intervals. They conclude that the 6% reinforced composite exhibits the highest resistance to salt spray and the least corrosion. Ravi Kumar prepared his Al7075 grade aluminium cenosphere composites fabricated by liquid metallurgy using stir casting technique [9]. They performed a salt spray test using a sodium chloride solution according to the ASTM B1117 standard. They report that corrosion resistance increases to 7.5% of the reinforcement with a further slight decrease in corrosion resistance as the weight percentage of the reinforcement increases. Zaki Uddin Ahmad and Bahaa Abdul Aleem performed salt spray tests on aluminium 6013 silicon carbide composites using a 3.5% sodium chloride solution containing suspended polystyrene particles [10]. The inhibitory effect of adding cerium chloride and sodium molybdate separately was investigated. They conclude that the level of protection provided by sodium molybdate is lower compared to cerium chloride. Sridhar Raja and Bhupesh Raja reported his 3%, 6%, 9% and 12% boron carbide powders of 104 microns. The salt spray test performance of was studied by agitation casting technology. They conclude that the composite has good corrosion resistance in sodium chloride media. P Raju, produced composites of cast aluminium alloy composites with alumina as a reinforcement by stir casting. They performed a salt spray test according to the ASTM B117-14 standard. They concluded that the composite material improved corrosion resistance by up to 24%. Malli Reddy Naresh and Shiva deliberate the corrosion behaviour of titanium diboride reinforced aluminium AA7700 matrix in salt spray tests. 5 wt%, 7.5 wt% and 10 wt% titanium diboride were added as reinforcement. The composite material was created using an in-situ casting process. They conclude that composites show less corrosion in salt spray tests.

Materials and Methods

Experimental details

The present study involves the use of Al-6013 alloy as matrix is existing in market as commercial material. Its composition is given in Table 1.

| Metal | Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Zinc | Titanium | Aluminium |

|---|---|---|---|---|---|---|---|---|---|

| Percentage | 0.6 | 0.5 | 1.1 | 0.2 | 0.8 | 0.1 | 0.2 | 0.1 | Balance |

TABLE 1. Composition (%) of aluminium 6013 alloy.

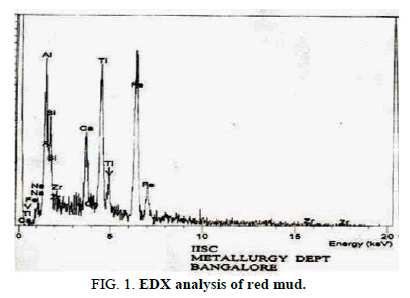

The fortification employed in this study is red mud particulates of size 50 micro meters-80 micro meters. It is an unwanted took after the extraction of aluminium from its ore bauxite. It’s obtained from HINDALCO, Renukoot district in Uttar Pradesh state of India. Its EDX analysis reveals that it contains oxides of iron, calcium, sodium, aluminium, titanium, zirconium etc.

Figure 1 given above shows the report of energy dispersive X-ray spectroscopy and Figure 2 is the photograph of bars of aluminium 6013 alloy. Figure 3 given below shows the red mud particulates used as fortification. Composite materials are produced by liquid melt metallurgical approach using vortex method employed via Ravi Shankar and Krupakara. It’s also called stir casting technique. Bottom pouring furnace is employed for casting. Figure 4 given below shows the base pouring furnace employed in the manufacture of complexes.

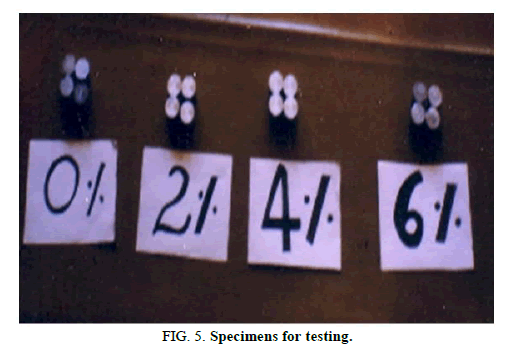

The raw material was heated to a temperature fairly above its ebullition and degasifying tablet such as perchloroethane was used to remove the caught bubbles. Then required amount of reinforcement is added and stirred well and from the bottom of the furnace the melt containing the reinforcement is directly added into initially heated cast iron moulds. Cylindrical bar castings were taken out from the moulds. Like this composite materials having 2,4 and 6 weight percentage of red mud particulates were casted. At the end the matrix alloy was also casted without reinforcement to compare the results after the test is over. The castings were exposed to machining to grow the cylindrical sample of dimension 20 mm diameter and 20 mm height. The matrix alloy was also subjected to machining. After casting the specimens for the test were machined from bar castings. The experiment samples were machined into normal discs of 20 mm diameter and 20 mm height. Figure 5 given below shows the specimens machined. Prior to testing, the specimen surfaces were polished to a mirror sheen using diamond paste in stages of 1.5 mm to 3 mm after being ground using silicon carbide paper with a 1000 grid size. The specimens were then subjected to microstructural examinations after being completely dried and rinsed with water and acetone.

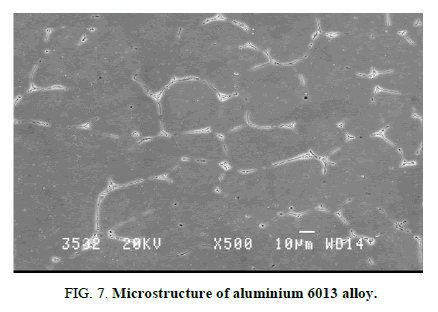

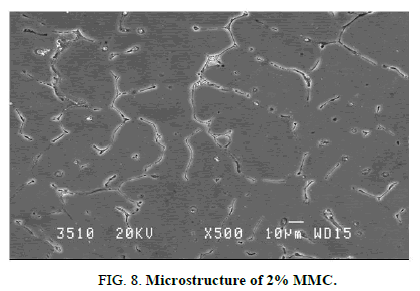

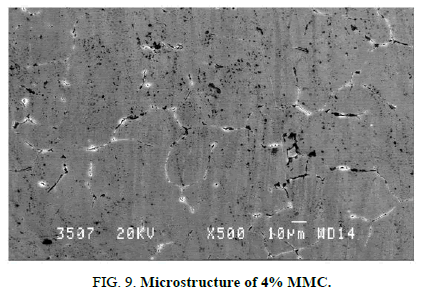

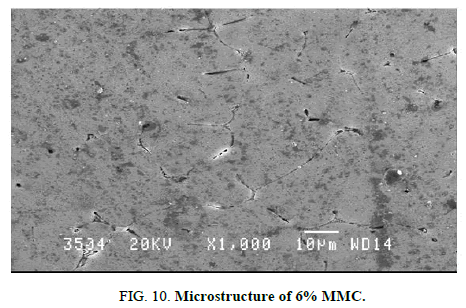

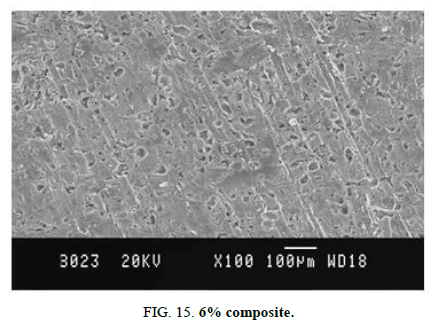

Figures 7-10 display the microscopic structure of the matrix and the composites obtained. In Figures 8-10 uniform distribution of reinforcement is observed.

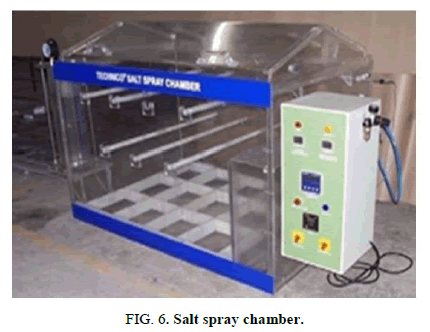

The instrument utilized for testing salt spray is a shut testing chamber, in which a salt arrangement (typically sodium chloride arrangement) is sprayed from the top with the assistance of a spout. Figure 6 given above shows the salt spray chamber used.

This will make an eroding domain in the testing chamber and afterward specimen inside will be presented to this consuming condition. Measured capacity of the salt splash chamber was discovered to be 420 dm3. The tests were performed by ASTM-B-117.Tests performed with an answer of sodium chloride are known as NSS (Neutral Salt Spray). The concentration of aqueousSodium chloride utilized was 5% and the pH of test medium utilized was 7.08. The specimens were cleaned with isopropylliquor, before the test. Hot, damp air is made by foaming compacted air through an air pocket (humidifying) tower containinghot de ionized water. Test temperature was maintained around 350°C ± 200°C. Salt solution is typically moved from arereservoir through a filter to the nozzle by a gravity feed framework. Volume of the test arrangement gathered every hour per 80cm2 territory of the bureau was 1.41 ml. At the point when the hot sticky air and the salt arrangement blend at the spout, it isatomized into a destructive mist. This makes a 100% relative dampness condition in the presentation zone. The specimens werepresented to the destructive mist for 72 hours. Later the examine specimens were washed with running water and dehydratedcompletely. Results were spoken to as testing hours in NSS without the presence of corrosion products.

Results and Discussion

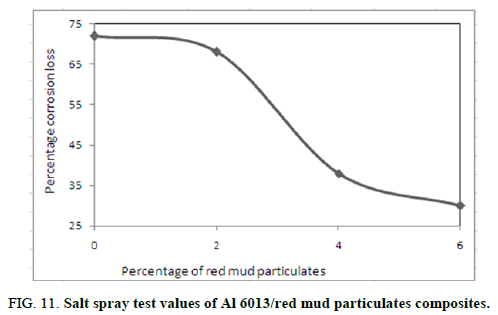

The samples were exposed to salt spray for about 73 hrs. after taking initial weight. Because at 73 hours some corrosion product formation was observed. Hence percentage corrosion loss was calculated after taking out the specimen from the chamber and cleaning the same for the removal corrosion product. Then washed with distilled water and acetone. Then air dried and final weight was taken. The percentage corrosion loss was calculated using the formula; CR=Initial weight-final weight × 100/Initial weight. The corrosion rates obtained were plotted against percentage of reinforcement to get the results in the form of graph. Figure 11 shows the results of salt spray tests.

74% of the base alloy was corroded after the 72 hours of exposure. Since no reinforcement was included in any form to resist the corrosion. The matrix alloy exposed to aggressive corrosion medium results in higher percentage of corrosion. However, the percentage of corrosion was decreased to 24% in the 6% red mud particulates reinforced composite. Red mud reinforcement goes about as an actual obstruction to the commencement and improvement of consumption pits and furthermore changes the miniature design of the lattice material.

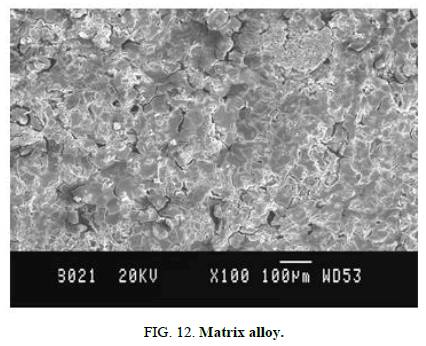

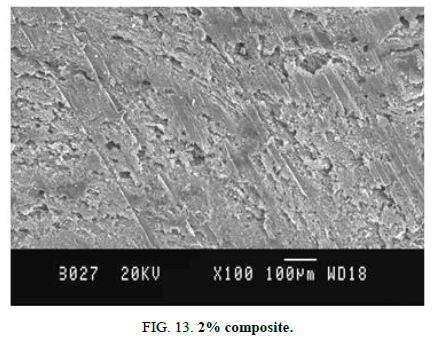

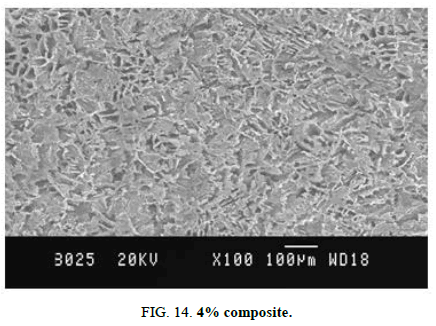

The percentage of corrosion in 2% and 4% red mud particulates reinforced composites lies between the unreinforced and 6% red mud particulates reinforced composites. The 2% red mud particulates reinforced composite shows 64% of the corrosion. Large change in the corrosion occurs in the case of 4% red mud particulates reinforced composite. The percentage of corrosion is further reduced to 34%. After the tests are over the specimens were again subjected microstructural studies. Figures 12-15 shows the microstructures of the alloy and composites after the salt spray tests.

Physical inspection of the specimens after salt spray test shows a few deep pits, flakes and cracks on the unreinforced matrix alloy. The unreinforced matrix alloy is severely damaged after exposure to neutral chloride solutions. Aluminiumoxide defensive film doesn’t totally cover the material surface. The first defensive film presents both summed up and restricted assault by chloride and furthermore gives indications of nucleation and development of another layer of aluminum hydroxide. A few cracks are seen on the surface of the 2% red mud particulates reinforced composites and no cracks in other metal matrix composite specimens. But a more widespread superficial pitting has been observed on 4% and 6% red mud particulates reinforced composites. Finally, it can be concluded that the damage on the surfaces of the specimen decreases with increase in reinforcement.

Conclusion

Stir casting strategy was utilized to fabricate aluminum 6013/red mud particulate supported composites. Salt spray test was led to test the corrosion properties of aluminum 6013/red mud composites in correlation with aluminum 6013 combination by splashing 5% sodium chloride arrangement in a salt spray chamber. Consequences of the test uncovers that the added red mud assumes a significant part in the control of corrosion in composites when contrasted and matrix combination. As the added content expands the corrosion rate diminishes with expansion in season of openness. Consequently, composites are more appropriate than matrix alloy in numerous applications.

References

- Pradeep Kumar GS, Keshavamurthy R, Kumari P, et al. Corrosion behaviour of TiB2 reinforced aluminium based in situ metal matrix composites. Perspect Sci. 2016;8:172-175.

- Krupakara PV, Kulkarni SN. Studies on the stress corrosion behaviour of aluminium 6061/red mud metal matrix composites. Int J Chem Sci.2022;7(3):503.

[Crossref]

- Chandrashekara KN, Narasimhamurthy B, Krupakara PV. Stress corrosion studies of aluminium 6013-red mud metal matrix composites. J Chem Chem Sci. 2017;7:640-646.

- Phanibhushana MV, Chandrappa CN, Niranjan HB. Experimental study of hematite reinforced aluminium metal matrix composites subjected to equal channel angular pressing. Mater Today Proc 2018;5(5):13282-13289.

[Crossref]

- Sathish T, Mohanavel V, Arunkumar T, et al. Investigation of mechanical properties and salt spray corrosion test parameters optimization for Aa8079 with reinforcement of Tin+Zro2. Materials. 2021;14(18):5260.

[Crossref] [Google Scholar] [PubMed]

- Ahmad Z, Aleem BA. Degradation of aluminium metal matrix composites in salt water and its control. Mater Des. 2002;23(2):173-180.

- Mallireddy N, Siva K. Investigation of microstructural, mechanical and corrosion properties of AA7010-TiB2 in-situ metal matrix composite. Sci Eng Compos Mater. 2020;27(1):97-107.

- Kumar RA, Akash SJ, Arunkumar S, et al. Fabrication and corrosion behaviour of aluminium metal matrix composites-A review. Mater Sci Eng. 2020;923(1):1205.

- Zakaria HM. Microstructural and corrosion behaviour of Al/SiC metal matrix composites. Ain Shams Eng J. 2014;5(3):831-838.

- Kumar VM, Venkatesh CV. A comprehensive review on material selection, processing, characterization and applications of aluminium metal matrix composites. Mater Res Exp. 2019;6(7):072001.