Review Article

, Volume: 12( 12)A Review on Biodegradation of Polymers

- *Correspondence:

- Dinesh KG , Department of Pharmaceutical Analysis and Quality Assurance, CMR College of Pharmacy, Hyderabad, Telangana, India, Tel: +919963330488; E-mail: dineshkumar.2431@gmail.com

Received: August 06, 2016; Accepted: August 23, 2016; Published: September 10, 2016

Citation: Dinesh KG. A Review on Biodegradation of Polymers. Biotechnol Ind J. 2016;12(12):109.

Abstract

The expression "polymer" gets from the antiquated Greek word polus, signifying "some, much" and meros, signifying "parts", and alludes to an atom whose structure is made out of various rehashing units. A polymer is an extensive particle (macromolecules) made out of numerous rehashed subunits, known as monomers. Biodegradable polymers are characterized as polymers included monomers connected to each other through practical gatherings and have unsteady connections in the spine. Polymer corruption is an adjustment in the properties – elasticity, shading, shape, and so forth of a polymer or polymer based item affected by one or more natural components, for example, warmth, light or chemicals. Compound or enzymatic corruption is intervened by water, catalysts, microorganisms. Grouping of biodegradable polymers taking into account the source like natural biodegradable polymers and synthetic biodegradable polymers. Biodegradable polymers have demonstrated their potential for the improvement of new, progressed and proficient DDS and equipped for conveying an extensive variety of bioactive materials. However, just few have entered the business sector since numerous medications confronts the issue of affectability to warmth, shear strengths and association between polymers. These issues can be overcome by completely understanding the debasement component to modify the discharge profile. Numerous engineered biodegradable polymers are accessible and as yet being produced for supported and focused on medication conveyance applications.

Keywords

Biodegradation; Mineralization; Polymer; Biodegradable

Introduction

The expression "polymer" gets from the antiquated Greek word polus, signifying "some, much" and meros, signifying "parts", and alludes to an atom whose structure is made out of various rehashing units. A polymer is an extensive particle (macromolecules) made out of numerous rehashed subunits, known as monomers. Monomers can be connected together in different approaches to give direct, fanned and cross connected polymers and so on [1-10].

Attributes of an ideal polymer

• Should be adaptable and have an extensive variety of mechanical, physical, substance properties.

• Should be non-lethal and have great mechanical quality and ought to be effectively regulated.

• Should be economical.

• Should be anything but difficult to create.

• Should be idle to host tissue and perfect with environment.

Biodegradable Polymers

Biodegradable polymers are characterized as polymers included monomers connected to each other through practical gatherings and have unsteady connections in the spine. They are separated into naturally adequate atoms that are metabolized and expelled from the body by means of ordinary metabolic pathways [11-20]. Based on biodegradability polymers are named: 1) Biodegradable polymers (e.g.: collagen, poly glycolic corrosive and etc.) and 2) Non-biodegradable polymers (e.g.: poly vinyl chloride, polyethylene and etc.).

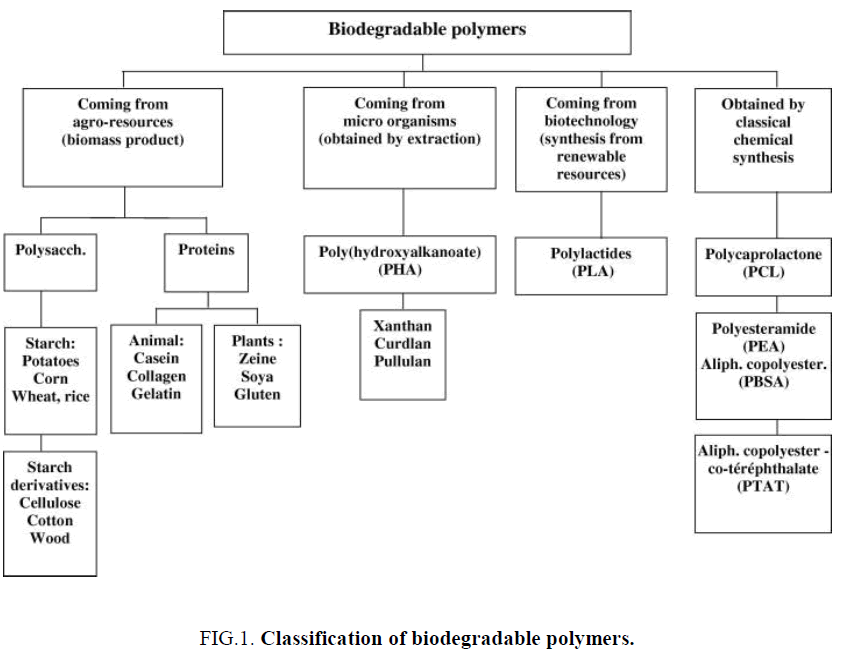

Classification of Biodegradable Polymers

Biodegradable polymers are to be classified as mentioned in below (Figure 1).

Polymer Degradation

Polymer corruption is an adjustment in the properties – elasticity, shading, shape, and so forth of a polymer or polymer based item affected by one or more natural components, for example, warmth, light or chemicals [21-30]. The term "biodegradation" is restricted to the portrayal of concoction procedures (compound changes that adjust either the atomic weight or solvency of the polymer). 'Bioerosion' might be limited to allude to physical procedures that outcome in weight reduction of a polymer gadget. The bioerosion of polymers is fundamentally of two sorts: Bulk disintegration, Surface disintegration.

Bulk disintegration

• Degradation happens all through the entire of the example.

• Ingress of water is quicker than the rate of corruption

E.g.: polylactic corrosive (PLA), polyglycolic corrosive (PGA).

Surface disintegration

• Sample is dissolved from the surface.

• Mass misfortune is quicker than the entrance of water into the mass.

E.g.: polyanhydrides, polyorthoesters.

Grouping of Biodegradable Polymers Taking into Account the Source

Synthetic biodegradable polymers [31-40]

Aliphatic poly(esters): These are set up by ring opening and polymerization of cyclic ester. Aliphatic polyesters include:

Poly(glycolic acid): Polyglycolide or polyglycolic corrosive (PGA) is a biodegradable, thermoplastic polymer and the least difficult straight, aliphatic polyester.

• It is an intense fiber-framing polymer.

• Due to its hydrolytic unsteadiness its utilization has been restricted.

• It has a glass move hoisted level of temperature between 35°C to 40°C., crystallinity, around 45.

• Its dissolving point is in the reach 55%, along these lines bringing about of 225°C to 230°C. insolubility in water.

• polyglycolide is debased by hydrolysis, and separated by specific chemicals.

• Applications: Used to convey drugs as microspheres, inserts and etc.,

• Case of medications conveyed incorporate steroid hormones, anti-microbials, against malignancy operators and etc.,

Polylactic acid: Polylactic corrosive or polylactide (PLA) is a thermoplastic aliphatic polyester got from renewable assets, for example, corn starch, custard items (roots, chips or starch) or sugarcane.

• It can biodegrade under specific conditions, for example, the nearness of oxygen, and is hard to reuse.

• Highly crystalline, high dissolving point, low dissolvability.

• Bacterial aging is utilized to create lactic corrosive from corn starch or natural sweetener.

• Applications: PLA is utilized as a part of the readiness of sutures or orthopedic gadgets.

Polycaprolactone: Polycaprolactone (PCL) is a biodegradable polyester.

• It has a low liquefying purpose of around 60°C.

• It has a glass move temperature of about -60°C.

• Slower corruption rate than PLA.

• It stays dynamic the length of a year for medication conveyance.

• Applications: Drug conveyance utilizations of PCL incorporates: Cyclosporin as nanoparticles, Ciprofloxacin as dental inserts.

Poly anhydrides: Highly responsive and hydrolytically insecure.

• Degrade by surface corruption without the requirement for impetuses.

• Aliphatic (CH2 in spine and side chains) polyanhydrides corrupt inside days.

• Aromatic (benzene ring as the side chain) polyanhydrides corrupt more than quite a long while.

• Excellent biocompatibility.

• Drug stacked gadgets arranged by pressure trim or microencapsulation.

• Suitable for transient medication conveyance.

• Used for immunization and confined tumor treatment [41-50].

Polyphosphazenes: Its hydrolytic steadiness/insecurity is controlled by change in side gathering appended to macromolecular spine.

• Used in the development of delicate tissue prosthesis, tissues like coatings, as material for vein prosthesis.

• Used for immobilization of antigen or compound.

• Use for medication conveyance under scrutiny.

• Based on side chain these are of 3 sorts: Hydrophobic phosphazenes, Hydrophilic phosphazenes, Amphiphilic phosphazenes.

Polyaminoacids: Aminoacid side-chains offer locales for medication connection.

• Low-level systemic lethality inferable from their comparability to actually happening amino acids.

• Investigated as suture materials.

• Artificial skin subtitutes.

• Limited relevance as biomaterials because of restricted dissolvability and processibility.

• Drug conveyance (hard to foresee drug discharge rate because of swelling).

• Polymers containing more than three or more amino acids may trigger antigenic reaction.

• Tyrosine determined polycarbonates created as high-quality degradable orthopedic inserts.

Natural biodegradable polymers

• Natural polymers are an alluring class of biodegradable polymers as they seem to be:

• Derived from regular sources

• Easily accessible

• Relatively shabby

E.g.: Albumin, Collagen, Dextran, Gelatin, Pectin, starch and so forth.

Collagen: Collagen is the most generally discovered protein in well evolved creatures and is the real supplier of quality to tissue.

• The number of biomedical applications in which collagen have been used is too high;it not just has been investigated for use in different sorts of surgery, beauty care products, and medication conveyance, additionally in bioprosthetic embeds and tissue designing of numerous organs too.

• It is utilized as sutures, Dressings, and so on.

Disadvantages: Poor dimensional solidness. Variability in medication discharge energy, Poor mechanical quality.

Applications: Majorly utilized as a part of visual medication conveyance framework.

Albumin: It is a noteworthy plasma protein part.

• It represents more than 55% of aggregate protein in human plasma.

• It is utilized to plan particulate medication conveyance frameworks [51-60].

Applications: Albumin small scale circles are utilized to convey drugs like Insulin, Sulphadiazene, 5-fluorouracil, Prednisolone and so forth. It is for the most part utilized as a part of chemotherapy, to accomplish high nearby medication fixation for moderately more time.

Dextran: Dextran is a complex extended polysaccharide made of numerous glucose atoms joined into chains of changing lengths.

• It comprises of α-D-1,6-glucose-connected glucan with side-affixes connected to the foundation of Polymer. Its mol.wt ranges from 1000 Daltons to 2,00,000 Daltons.

• Applications: Used for colonic conveyance of medication as gels.

Gelatin: Gelatin is a blend of peptides and proteins created by fractional hydrolysis of collagen, extricated from the bubbled bones, connective tissues, organs and a few digestion systems of creatures. Gelatin is an irreversible hydrolyzed type of collagen, physicochemical properties relies on upon the wellspring of collagen, extraction strategy and warm corruption.

Applications: Employed as covering material and Gelatin micropellets are utilized for oral controlled conveyance of medications.

Factors Affecting Biodegradation of Polymers

Morphological factors

• Shape and size

• Variation of dissemination coefficient and mechanical hassles

Chemical factors

• Chemical structure and organization

• Presence of ionic gathering and setup structure

• Molecular weight and nearness of low sub-atomic weight mixes

Physical factors

• Processing condition

• Sterilization process

Advantages of biodegradable polymers

• Localized conveyance of medication

• Sustained conveyance of medication

• Stabilization of medication

• Decrease in dosing recurrence

• Reduce symptoms

• Improved persistent consistence

• Controllable debasement rate

Applications of biodegradable polymers

• Polymer framework for quality treatment.

• Biodegradable polymer for visual, tissue building, vascular, orthopedic, skin glue and surgical pastes.

• Biodegradable medication framework for helpful specialists, for example, against tumor, antipsychotic operator, mitigating operator

• Polymeric materials are utilized as a part of and on soil to enhance air circulation, and advance plant development and wellbeing.

• Many biomaterials, particularly heart valve substitutions and veins, are made of polymers like Dacron, Teflon and polyurethane.

Conclusion

• Numerous engineered biodegradable polymers are accessible and as yet being produced for supported and focused on medication conveyance applications.

• Biodegradable polymers have demonstrated their potential for the improvement of new, progressed and proficient DDS and equipped for conveying an extensive variety of bioactive materials.

• However, just few have entered the business sector since numerous medications confronts the issue of affectability to warmth, shear strengths and association between polymers.

• These issues can be overcome by completely understanding the debasement component to modify the discharge profile.

References

- Tiwari G, Tiwari R, Sriwastawa B, et al. Drug delivery systems: An updated review. Int J Pharm Investig. 2012;2:2-11.

- Gupta S, Kumar P. Drug Delivery Using Nanocarriers: Indian Perspective. Proc Natl Acad Sci India Sect B: Biol Sci. 2012;82:167-206.

- Pillai O, Panchagnula R. Polymers in drug delivery. Curr Opin Chem Biol. 2001;5:447-51.

- Langer R. Drug delivery and targeting. Nature. 1998;392:5-10.

- Shaik MR, Korsapati M, Panati D. Polymers in Controlled Drug Delivery Systems. International Journal of Pharma Sciences. 2012;2:112-6.

- Reis RL, Cunha AM, Allan PS, et al. Mechanical behaviour of injection- molded starch based polymers. Polym Adv Technol. 1996;7:784-90.

- Seal BL, Otero TC, Panitch A. Polymeric biomaterials for tissue and organ regeneration. Mater Sci Eng Rep. 2001;3:147-230.

- Di Martino A, Sittinger M, Risbud MV. Chitosan: a versatile biopolymer for orthopaedic tissue-engineering. Biomaterials. 2005;26:5983-90.

- Lee SB, Kim YH, Chong MS, et al. Study of gelatin-containing artificial skin V: fabrication of gelatin scaffolds using a salt-leaching method. Biomaterials. 2005;26:1961-8.

- Mohanty AK, Misra M, Hinrichsen G. Biodegradable polymers and biocomposites: An overview. Macromol Mater Eng. 2000;277:1-24.

- Kottke MJ, Edward MR. Tablet Dosage Forms. In: Banker GS, Rhodes CT, editors. Modern Pharmaceutics. New York: Marcel Dekker Inc; 2002. p. 287-333.

- Alam AS, Parrott EL. Effect of aging on some physical properties of hydrochlorothiazide tablets. J Pharm Sci. 1971;60:263-6.

- Angelova N, Hunkeler D. Rationalizing the design of polymeric biomaterials. Trends Biotechnol. 1999;17:409-21.

- Brocchini S, Duncan R. Pendant drugs release from polymers. In: Encyclopaedia of Controlled Drug Delivery. New York: John Wiley and Sons; 1999. p. 786-816.

- Colthurst MJ, Williams RL, Hiscott PS, et al. Biomaterials used in the posterior segment of the eye. Biomaterials. 2000;21:649-65.

- Mao HQ, Kdaiyala I, Leong KW, et al. Biodegradable Polymers: poly (phosphoester). In: Encyclopaedia of Controlled Drug Delivery. New York: John Wiley and Sons; 1999. p. 45-60.

- Nair LS, Laurencin CT. Polymers as Biomaterials for Tissue Engineering and Controlled Drug Delivery. Adv Biochem Eng Biotechnol. 2006;102:47-90.

- Kotwal VB, Saifee M, Inamdar N, et al. Biodegradable polymers: Which, when and why? Indian J Pharm Sci. 2007;69(5):616-25.

- Manthina M, Kalepu S, Padavala V. Oral lipid-based drug delivery systems – an overview. Acta Pharmaceutica Sinica B. 2013;3:361-72.

- Vyas SP, Khar RK. Controlled Drug Delivery – Concepts and Advances. 2nd ed. Vallabh Prakashan. 2012. pp. viii+664.

- Lakshmi NS, Cato LT. Polymers as Biomaterials for Tissue Engineering and Controlled Drug Delivery. Adv Biochem Eng Biotechnol. 2006;102:47-90.

- Vert M, Makromol A. Synthesis of Degradable Polyesters. Polymer J. 1992;24:1109-17.

- Vainionpaa S, Rokkanen P, Tormala P. Surgical application of biodegradable polymers in human tissue. Prog Polym Sci. 1989;14:679-716.

- Jain NK. Controlled and novel drug delivery system. 1st ed. CBS Publication. 27-51.

- Li J, Peng L, Sun J, et al. Slow-Release Drug Delivery System with Polylactic Acid Hydrogels in Prevention of Tracheal Wall Fibroplasia. Arch Clin Exp Surg. 2012;1:1-7.

- Frazza EJ, Schmitt EE. A new absorbable suture. J Biomed Mater Res. 1971;5:43-58.

- Benicewicz BC, Hopper PK. Biodegradable Poly (Lactic Acid):Synthesis, Modification, and processing. J Bioact Compat Polym. 1990;5:453.

- Dinarvand R, Moghadam SH, Mohammadyari-Fard L, et al. Preparation of biodegradable microspheres and matrix devices containing naltrexone. AAPS Pharm Sci Tech. 2003;4:E34.

- Park TG, Lu WQ, Crotts GJ. Evaluation of controlled release products in vitro. 1995;33:211-22.

- Miller RA, Brady JM, Cutright DE. Degradation rates of oral resorbable implants (polylactates and polyglycolates): rate modification with changes in PLA/PGA copolymer ratios. J Biomed Mater Res. 1977;11:711-9.

- Repanas A, Wolkers WF, Gryshkov O, et al. Coaxial Electrospinning as a Process to Engineer Biodegradable Polymeric Scaffolds as Drug Delivery Systems for Anti-Inflammatory and Anti-Thrombotic Pharmaceutical Agents. Clin Exp Pharmacol. 2015;5:192.

- Rahmani V, Shams K, Rahmani H. Nanoencapsulation of Insulin Using Blends of Biodegradable Polymers and In Vitro Controlled Release of Insulin. J Chem Eng Process Technol. 2015;6:228.

- Gavasane AJ, Pawar HA. Synthetic Biodegradable Polymers Used in Controlled Drug Delivery System:An Overview. Clin Pharmacol Biopharm. 2014;3:121.

- Kong KV, Liao LD, Goh D, et al. Novel Biodegradable Polymer Tethered Platinum (II) for Photoacoustic Imaging. J Nanomed Nanotechnol. 2014;5:223.

- Gleadall A, Pan J. Computer Simulation of Polymer Chain Scission in Biodegradable Polymers. J Biotechnol Biomater. 2013;3:154.

- Carr D, Yu NYC, Fitzpatrick J, et al. Synergy between rhBMP-2 and IKK-Inhibitor PS-1145 Delivered via a Porous Biodegradable Polymer Implant. J Tissue Sci Eng. 2012;S1:003.

- Loretta OO, Stephen E, Ezeata A, et al. In Vitro Biodegradation of Palm Oil Mill Effluent (POME) by Bacillus subtilis, Pseudomonas aeruginosa and Aspergillus niger. J Bioremed Biodeg. 2016;7:361.

- Prabhavathi P, Rajendran R, Karthik Sundaram S, et al. Molecular Docking Studies on Potent Adsorbed Receptor of Protein:A New Target for Biodegradation of Indigo Dye. J Bioremed Biodeg. 2016;7:356.

- Alariqi SAS, Mutair AA, Singh RP. Effect of Different Sterilization Methods on Biodegradation of Biomedical Polypropylene. J Environ Anal Toxicol. 2016;6:373.

- Abd El-Ghany TM, Masmali IA. Fungal Biodegradation of Organophosphorus Insecticides and their Impact on Soil Microbial Population. J Plant Pathol Microbiol. 2016;7:349.

- Jablonski MR, Ranicke HB, Qureshi A, et al. Novel Photo-fenton Oxidation with Sand and Carbon Filtration of High Concentration Reactive Dyes both with and without Biodegradation. J Textile Sci Eng. 2016;6:251.

- Prince RC, Kelley BA, Butler JD. Three Widely-Available Dispersants Substantially Increase the Biodegradation of Otherwise Undispersed Oil. J Marine Sci Res Dev. 2016;6:183.

- Anike FN, Yusuf M, Isikhuemhen OS. Co-Substrating of Peanut Shells with Cornstalks Enhances Biodegradation by Pleurotus ostreatus. J Bioremed Biodeg. 2016;7:327.

- Isiodu GG, Stanley OH, Victor E, et al. Role of Plasmid-Borne Genes in the Biodegradation of Polycyclic Aromatic Hydrocarbons (PAHs) by Consortium of Aerobic Heterotrophic Bacteria. J Pet Environ Biotechnol. 2016;7:264.

- Owhonka A, Gideon OA. The Role of Aerobic Microorganisms in the Biodegradation of Petroleum Hydrocarbons Laboratory Contaminated Groundwater. Fermentol Techno. 2015;4:122.

- Lim SJ. Biodegradation:Enzymes Evolution. J Bioremed Biodeg. 2015;6:e168.

- Shu CH, Jaiswal R, Shih JS. Improving Biodegradation of Rice Straw Using Alkaline and Aspergillus niger Pretreatment for Methane Production by Anaerobic Co-Digestion. J Bioprocess Biotech. 2015;5:256.

- Elghonemy D. Role of Microbial Enzymes in the Biodegradation of Rice Straw via Biotechnological Techniques. J Rice Res. 2015;3:e120.

- Saborimanesh N, Mulligan CN. Effect of Sophorolipid Biosurfactant on Oil Biodegradation by the Natural Oil-Degrading Bacteria on the Weathered Biodiesel, Diesel and Light Crude Oil. J Bioremed Biodeg. 2015;6:314.

- Chikere CB, Obieze CC, Okerentugba P. Molecular Assessment of Microbial Species Involved in the Biodegradation of Crude Oil in Saline Niger Delta Sediments Using Bioreactors. J Bioremed Biodeg. 2015;6:307.

- Ipeaiyeda AR, Nwauzor GO, Akporido SO. Biodegradation of Polycyclic Aromatic Hydrocarbons in Agricultural Soil Contaminated with Crude Oil from Nigeria Refinery using Pleurotus sajor-caju. J Bioremed Biodeg. 2015;6:301.

- Manoj B. Biodegradation of Coal Minerals by Gluconic Acid and its Effect on the Stacking Structure of Carbon:An Investigation. J Bioremed Biodeg. 2015;6:306.

- El Mahdi AM, Aziz HA, Abu Am SS, et al. Performance of Isolated Kocuria sp. SAR1 in Light Crude Oil Biodegradation. J Bioremed Biodeg. 2015;6:303.

- Natália Alvarenga, Willian G Birolli, Marcia Nitschke, et al. Biodegradation of Chlorpyrifos by Whole Cells of Marine-Derived Fungi Aspergillus sydowiiand Trichoderma sp. J Microb Biochem Technol. 2015;7:133-9.

- Oje Obinna A, Ubani Chibuike S, Onwurah INE. Variation in the Carbon (C), Phosphorus (P) and Nitrogen (N) Utilization during the Biodegradation of Crude Oil in Soil. J Pet Environ Biotechnol. 2015;6:206.

- Mohapatra S, Pandey M. Biodegradation of Hexachlorocyclohexane (HCH) Isomers by White Rot Fungus, Pleurotus florida. J Bioremed Biodeg. 2015;6:280.

- Paniagua-Michel J, Rosales A. Marine Bioremediation - A Sustainable Biotechnology of Petroleum Hydrocarbons Biodegradation in Coastal and Marine Environments. J Bioremed Biodeg. 2015;6:273.

- Chauhan A, Singh J. Biodegradation of DDT. J Textile Sci Eng. 2015;5:183.

- Godheja J, Shekhar SK, Modi DR. Biodegradation of One Ring Hydrocarbons (Benzene and Toluene) and Two Ring Hydrocarbons (Acenapthene and Napthalene) by Bacterial Isolates of Hydrocarbon Contaminated Sites Located in Chhattisgarh:A Preliminary Study. J Pet Environ Biotechnol. 2015;6:202.

- Kumar A, Singh C, Saini P. Biodegradation of Feather by Microsporum fulvum singly or in Combination with Other Fungi. J Bioremed Biodeg. 2014;5:26.