Original Article

, Volume: 13( 3)Studies on Development of Non-Alcoholic Beverage from Grapes

- *Correspondence:

- Nithya Priya S , Department of Biotechnology, Kumaraguru College of Technology, Chinnavedampatti (Post), Saravanampatti, Coimbatore ? 641 049, India, Tel: 0422 266 1100; E-mail: nithyapriya.s.bt@kct.ac.in

Received: April 12, 2017; Accepted: May 02, 2017; Published: May 04, 2017

Citation: Priya NS, Vani JB. Studies on Development of Non-Alcoholic Beverage from Grapes. Biotechnol Ind J. 2017;13(3):136.

Abstract

Ready-to-serve beverage of grapes are a product with severe shelf life problems. Alcoholic fermentation, Quality loss, color changes and mould contamination are greatly influenced the quality of grape beverage. Limiting or preventing the growth of undesirable microbial flora in grape juice for the inhibition of alcoholic fermentation is one of the main goal of preservation. The present work was to investigate the effects of preservatives such as sodium benzoate, potassium meta bisulphite and combination of both (potassium meta bisulphite+sodium benzoate) in grape juice preservation. Initially various pulp concentration (8%, 10%, 12%, 14%, 16%) of grape juice was taken and preserved with sodium benzoate of 140 mg/l. Then sugar content was optimized to 15ºBrix and preservatives of sodium benzoate (140 mg/l), potassium metabisulphite (120 mg/l) and combination of both 60 mg/l+60 mg/l) were used for preservation and storage studies were conducted. The Organoleptic studies of preserved grape juice such as alcohol estimation indicates that sodium benzoate alone and combination of sodium benzoate and potassium meta bisulphte showed significant preservation effect in grape juice. This study nuances the application of the above mentioned Chemical preservatives which were used under the permissible limits by FSSAI would not cause much problems in human health, thus it can be commercially used.

Keywords

Grape juice; Inhibition of alcoholic fermentation; Chemical preservatives; Storage studies

Introduction

Fruits and vegetables are important constituents of the diet and provide significant quantities of nutrients, especially vitamins, sugars, minerals and fiber. Daily consumption of fruits and vegetables reduce the risk of cancer, heart disease, premature aging, stress and fatigue primarily due to the integrated action of oxygen radical scavengers such as β- carotene and ascorbic acid plus calcium and dietary fiber. Due to the perishable nature of the fruits and vegetables they require immediate processing to avoid post-harvest losses (20% to 25%). Fruit beverages have higher nutritional, medicinal and calorific values compared to synthetic beverages [1]. Therefore, fruit juices for the preparation of ready-to-serve beverage may be a convenient alternative for the utilization of fruits. It has been reported that the organoleptic quality of RTS beverage prepared from juice could be increased by the addition of spice extracts of ginger, black pepper, mint, cardamom and cumin etc.

Grape is one of the most popularly produced and globally well-known fruit crop. It was reported that consumption of grape products at moderate level helps in prevention of aging related diseases. Microbial contamination affects quality of grape juice. However, yeast contamination of grape juice may occur and may lead to fermentation. Fermentation pathways start with glucose, this is because it is the simplest molecule, requiring the fewest catalytic steps, to enter into a pathway of glycolysis and central metabolism. Thus the pathway is operated by microorganisms to produce ethanol and CO2.Thus beverages were preserved using 70 ppm SO2, 120 ppm sodium benzoate, and pasteurization at 85°C for 15 min.

Nutritional or phytochemical properties can be improved by blending which offers to adjust sugar/acid ratios and compensate undesirable juice consistency [2]. Juices with pH 3.5 adjusted using organic acids (citric, malic and tartaric acids at 0.15% each and lactic acid at 0.1%) and preservatives (Sodium benzoate and Potassium sorbate at 0.1% each and combination of both at 0.05%) can be used. TSS, pH, acidity, reducing sugar, total sugar, ascorbic acid and ß-carotene was measured by standard method.

Materials and Methods

Materials

Grapes was purchased from a local market. Sugar, Sodium benzoate, Potassium meta bisulphite, Citric acid were purchased from local chemical stores. Ethanol, NaOH, phenolphthalein solution, Potassium dichromate, conc. H2SO4, sodium sulphite, sodium potassium tartarate, phenol were purchased from sigma Aldrich.

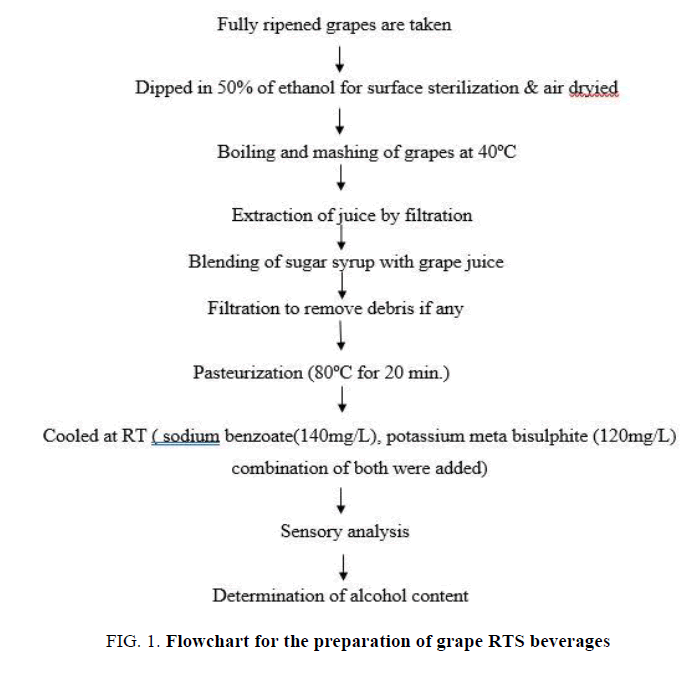

Production process of grape juice

Cleaning is the first step in fruit juice manufacturing because fermentation is better controlled and it prevents post decay of grapes. Unwanted inorganic materials (soil, stones, or metallic pieces) are eliminated by putting the grapes in a water bath or by manual selection and removal of rotten bunches [3]. The last step was dipped in a 50% ethanol to reduce the microbial load on the berries. After cleaning, grapes are crushed to facilitate juice extraction during the pressing step. Flowchart for the preparation of grape RTS beverages is represented in Figure 1.

Organoleptic studies of grape RTS beverage

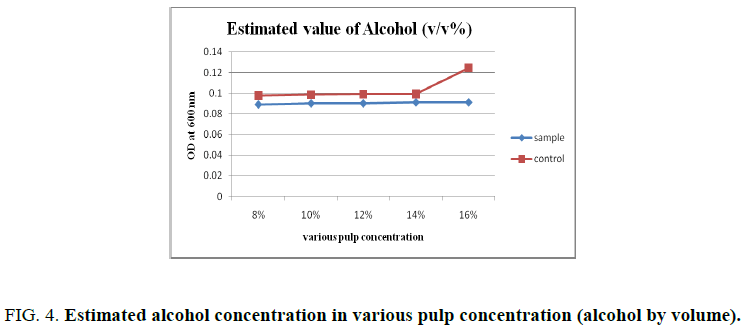

Initially grape juice of various pulp concentration was estimated for alcohol content. For 10 days of storage period pH, ºBrix values was also estimated.

Optimized grape juice

The sugar content optimized to 15ºBrix, its physico-chemical analysis was done such as estimation of TSS, pH, titrable acidity, ºBrix , total sugars, reducing sugars and also its alcohol content. The pH of the periodic samples was determined by using Digital pH meter. Total soluble solids (TSS) in juice were determined by using Erma hand refractometer of 0-32 ºBrix. Titrable acidity was expressed as per cent acidity and analyzed. Reducing sugars were estimated by DNSA method, total sugars were estimated by phenol-sulphuric acid method,percent of ethanol in alcoholic samples was estimated by spectrophotometer at 600 nm.

Results and Discussion

Organoleptic studies of grape RTS beverage

Color change: Fresh juice of 10 ml, which is added by 140 mg /L concentration of Sodium Metabisulphate leads color changes from pink to yellow.

Thus the fruit juice color was changed. The color changes are by anthocyanin content and its structural block by SO2.

Physico-chemical analysis of different pulp concentration of grape juice

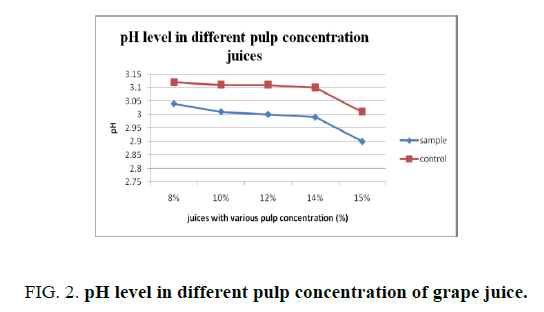

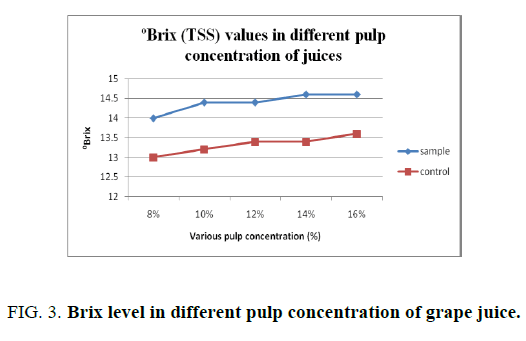

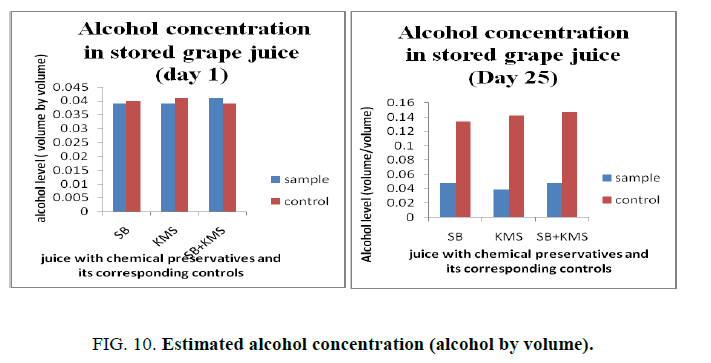

In Figure 2 some differences in the pH level of 10 days of stored different pulp concentration of grape juice when compared to control samples. Decrease of pH level indicates that increase in acidity of both control and samples. Figure 3 Indicates that decrease in ºBrix of sample and its corresponding controls [4]. If the brix is off, the nutritional value of the product changes. The brix level for ready-to-serve beverage is varies, control contains 13ºBrix and the sample contains 14ºBrix. Thus decrese in ºBrix levels leads to fermentation. Figure 4 shows that, significant difference in the alcohol by volume of samples when compared to control samples. The micro-organisms which are in the control samples leads to alcoholoic fermentation in grape juice.

Sugar content optimized grape juice and its storage studies

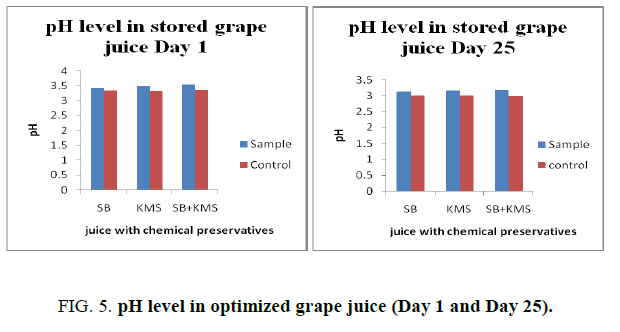

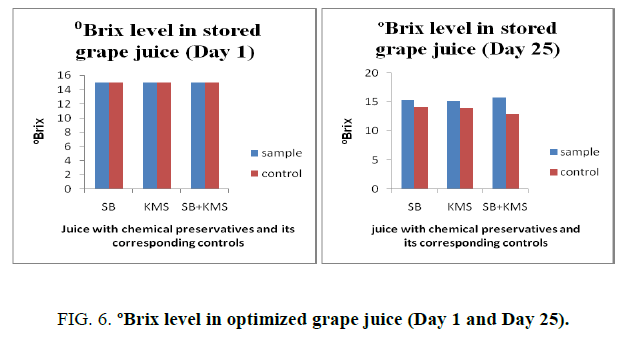

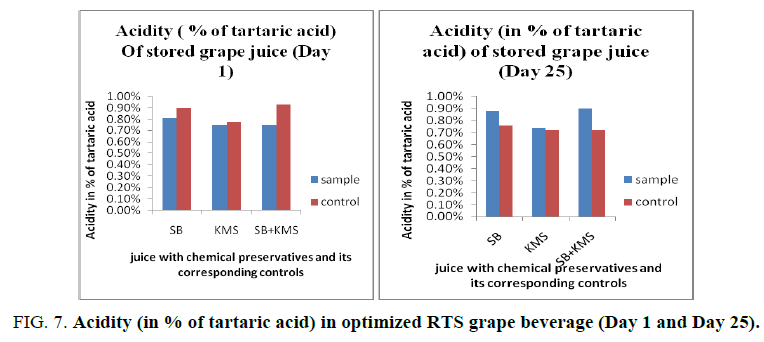

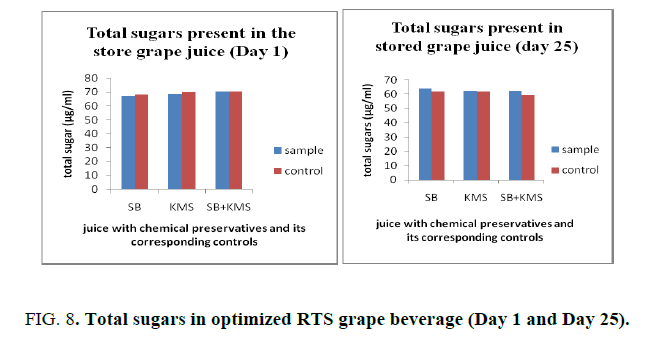

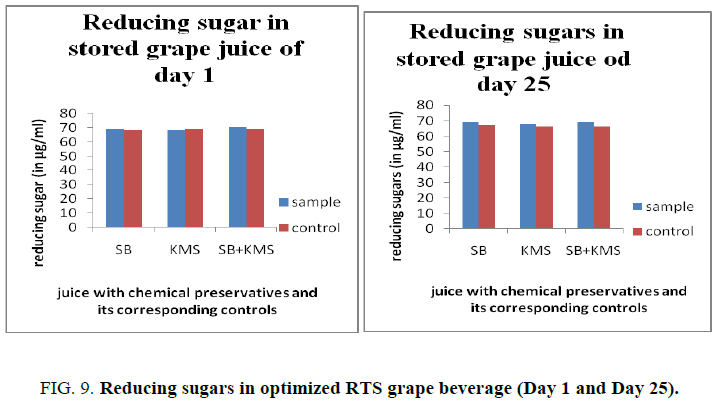

Figure 5 indicates some differences in the pH level of 25 days of optimized and stored grape juice when compared to Day 1 samples. Decrease of pH level indicates that increase in acidity of both control and samples. Low pH of the juice will inhibit the microorganisms. Addition of chemical preservatives changes the pH of the grape juice. Temperature was also an one of the important factor for decrease of the pH. When the temperature increases pH will get decreased. Thus citric acid is begins to dissociate, there by number of H+ ions also increased. It results in low pH of stored grape juice. ºBrix (TSS) is a scale based value, 1ºBrix is one gram of sucrose in 100 grams of solution. Decrease in ºBrix values indicates that alcoholic fermentation in stored grape juice. The sugar content of stored grape juice was optimized to 15 ºBrix (TSS), after storage of 25 days shows significant differences in the sugar content of grape juice (Figure 6) Acidity in % of tartaric acid was estimated by titration method. Since, the major organic acid which is present in grape juice is tartaric acid. Determination of acidity is important to estimate the organoleptic studies of grape juice, thus the high acid content leads to sour taste in grape juice. Here the acidity is increased, and the organoleptic characteristics are changed (Figure 7). The reducing sugars and total reducing sugars which are estimate in Day 1 and Day 25 sample indicates insignificant difference in samples and significant differences in controls (Figure. 8 and 9). Figure. 9 indicates that juice with chemical preservatives are inhibited from the fermentation of microbes. And there is no fermentation of grape juice. The crystals of KMS reacts with the acids present in it and the SO2 is released and forms sulphurous acid with the water of juice, which retards the growth of bacteria, yeast, fungi, and moulds. Absorption of benzoic acid in to the cell decreases the intracellular pH and there is no anaerobic fermentation of glucose, thus it inhibits the growth and survival of the microorganisms. Chemical food preservatives which were added in very low quantities (0.1%), which do not alter the organoleptic properties of the juices, also it prevents oxidation in grape juice (Figure. 10).

Conclusion

The present study showed that shelf life of beverages can be extended by adjusting the juice quantity and º Brix (TSS) value. The chemical preservatives such as SB, KMS, combination of both were inhibit the growth of microbes and it can be stored for several months. Thus thermal processing and preservation by chemical preservatives is a useful approach for fruit RTS (ready-to-serve beverage) beverage preservation. The Organoleptic studies of preserved grape juice and its alcohol estimation indicates that sodium benzoate alone and combination of sodium benzoate and potassium meta bisulphte showed significant preservation effect in grape juice. The products based on these techniques show many advantages such as the retention of sensorial qualities and nutritional values. Chemical preservatives which are used under the permissible limits by FSSAI would not cause much problems in human health, thus it can be commercially used.

References

- Hui YH.Handbook of fruits and fruit processing. John Wiley and Sons, UK.2006.

- Iriti M,Faoro F. Health-promoting effects of grape bioactive phytochemicals.In: Complementary and Alternative Therapies in the Aging Population.2011; 4:445.

- Rajashekhara E, Suresh ER, Ethiraj S. Modulation of thermal resistance of ascospores of Neosartoryafischeri by acidulants and preservatives in mango and grape juice.Food Microbiology.2000; 17(3): 269-75.

- Sindumathi G,Premalatha MR. Development and storage studies of naturally flavored papaya-pineapple blended ready-to-serve (RTS) beverages. International Journal of Science and Research. 2015; 4:856-60.